Hydrofining method of secondarily processed gasoline fractions

A technology of hydrofining and gasoline fractionation, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of long process, reduced heat exchange efficiency, and high content, and achieves small investment and high pressure drop. , the effect of extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

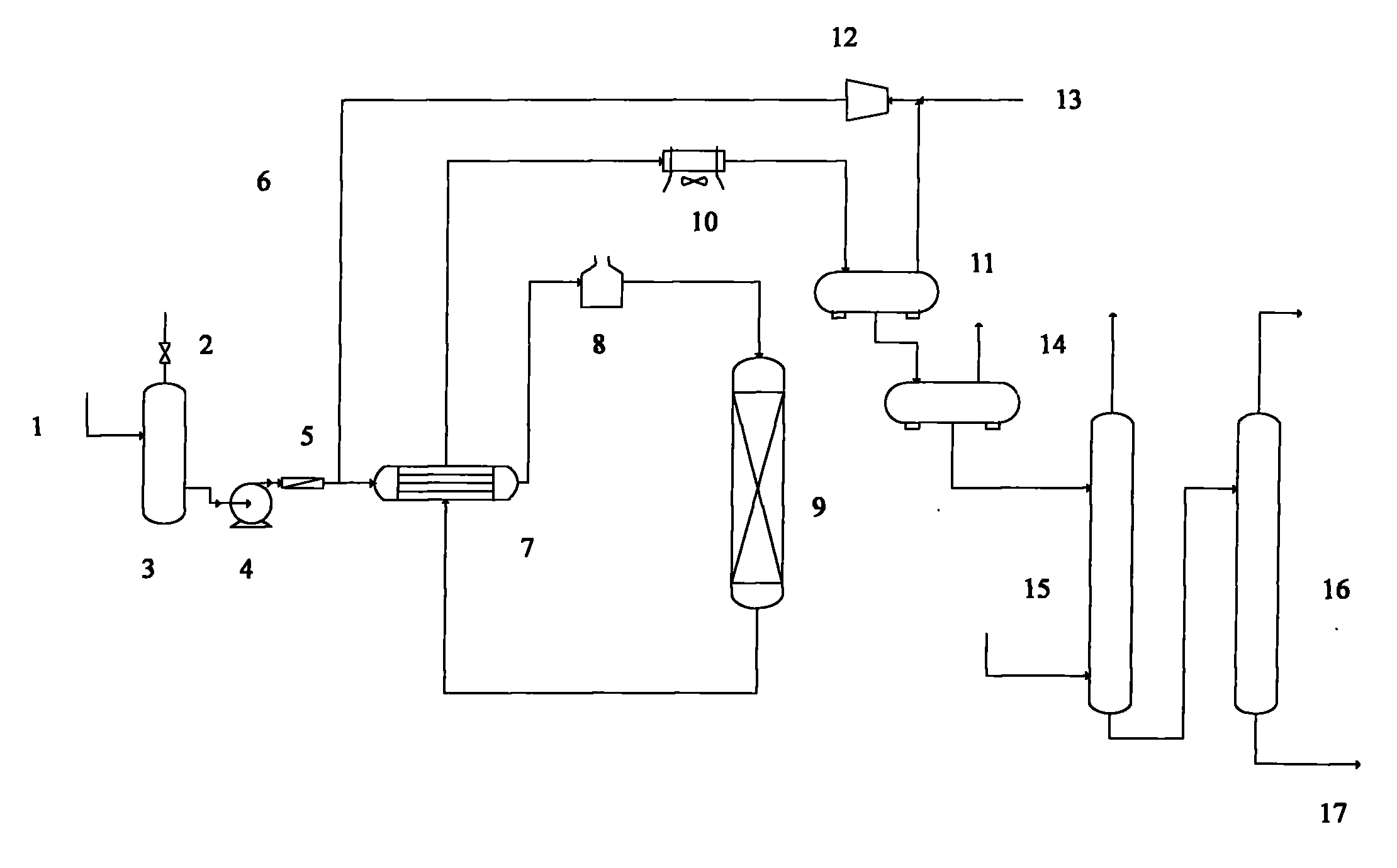

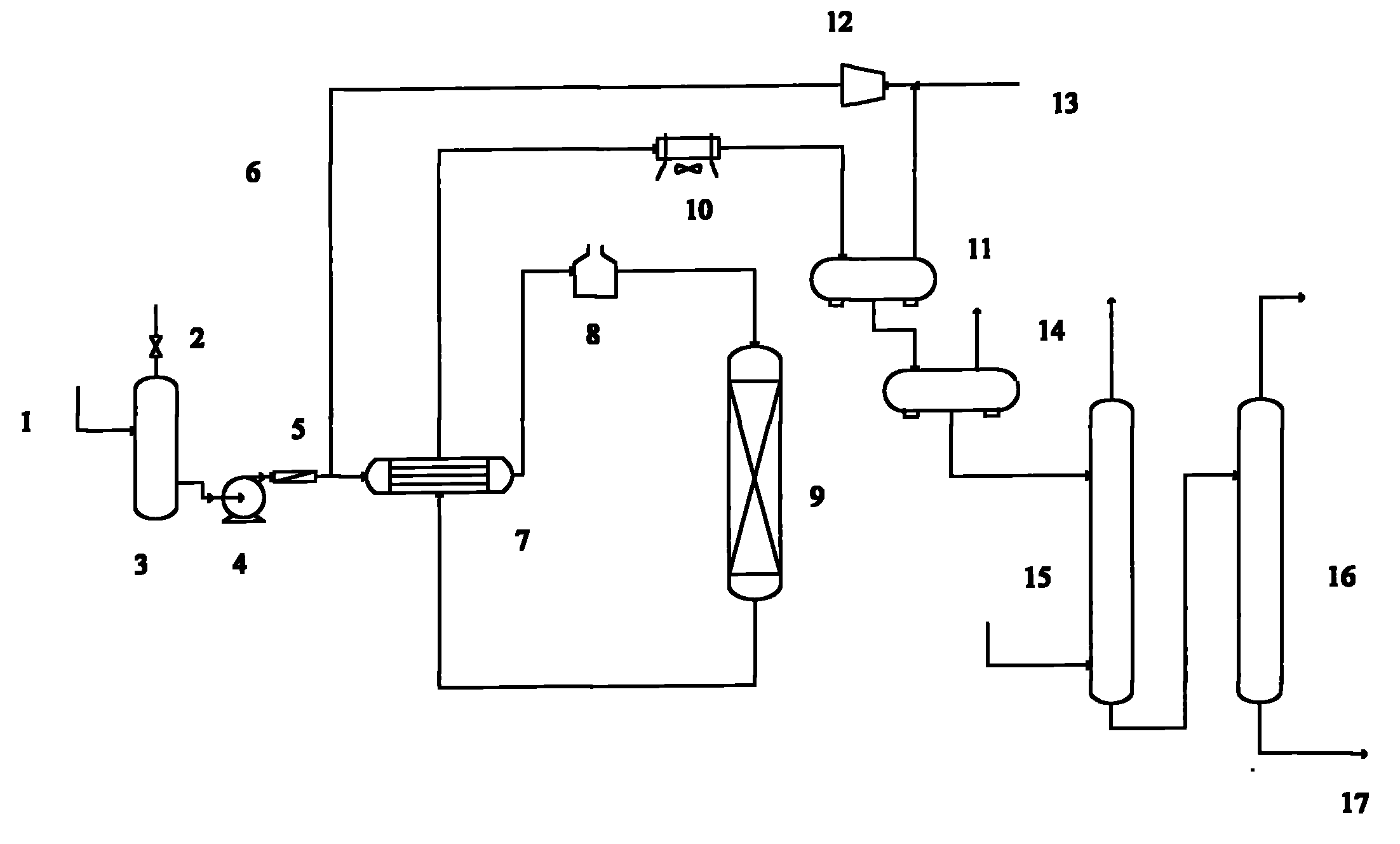

Image

Examples

Embodiment 1

[0027] Example 1 - Hydrotreating of Coker Gasoline Distillate

[0028] See Table 1 for the properties of the raw material oil, see Table 2 for the operating conditions of the de-diolefin heat transfer mild pre-hydrogenation equipment and hydrogenation reactor, and see Table 3 for the properties of the hydrogenation products.

[0029] Table 1 Example 1 Raw Oil Properties

[0030] name

coker gasoline

Density (20℃), g / cm 3

0.7350

Distillation range, ℃

IBP

30

10%

58

50%

132

90%

195

EBP

220

Diene value, gI / 100g

6.4

Bromine value, gBr / 100mL

45

[0031] Table 2 Example 1 Heat exchange and mild pre-hydrogenation equipment and hydrogenation reactor operating conditions

[0032] catalyst

FZC-103 catalyst

FH-98 catalyst

0.60

0.35

pressure, MPa

3.8

3.8

Hydrogen oil volume ratio

300 ...

Embodiment 2

[0035] Example 2-pyrolysis gasoline hydrotreating

[0036] See Table 4 for the properties of the raw material oil, see Table 5 for the operating conditions of the heat exchange and mild pre-hydrogenation equipment and hydrogenation reactor, and see Table 6 for the properties of the hydrogenation products.

[0037] Table 4 Example 2 Raw Oil Properties

[0038] name

pyrolysis gasoline

Density (20℃), g / cm 3

0.746

Distillation range, ℃

IBP

35

10%

65

50%

134

90%

198

EBP

229

Diene value, gI / 100g

7.9

Bromine value, gBr / 100mL

65

[0039] Table 5 Example 2 Heat exchange and mild pre-hydrogenation equipment and hydrogenation reactor operating conditions

[0040] catalyst

SHT catalyst

FH-40C catalyst

0.45

0.35

pressure, MPa

4.0

4.0

Hydrogen oil volume ratio

400

400

volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com