Welding system for pipeline formation

A technology of welding system and pipeline, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the oil system is prone to deformation, the arrangement of components in the oil system is easy to interfere, and the relative position and The overall positioning is not easy to determine and other problems, to achieve the effect of realizing the control of welding deformation, improving labor productivity and realizing the requirements of interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

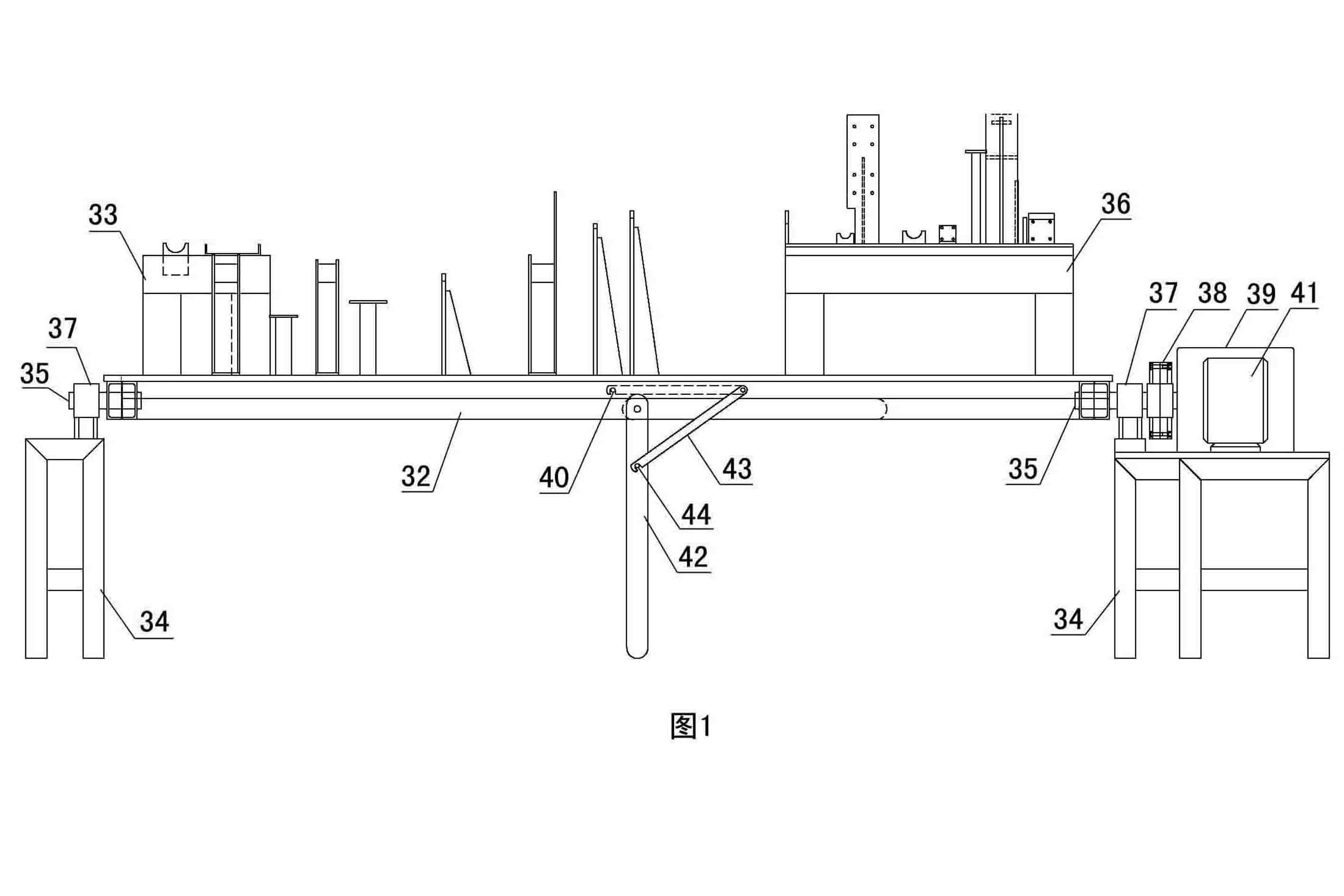

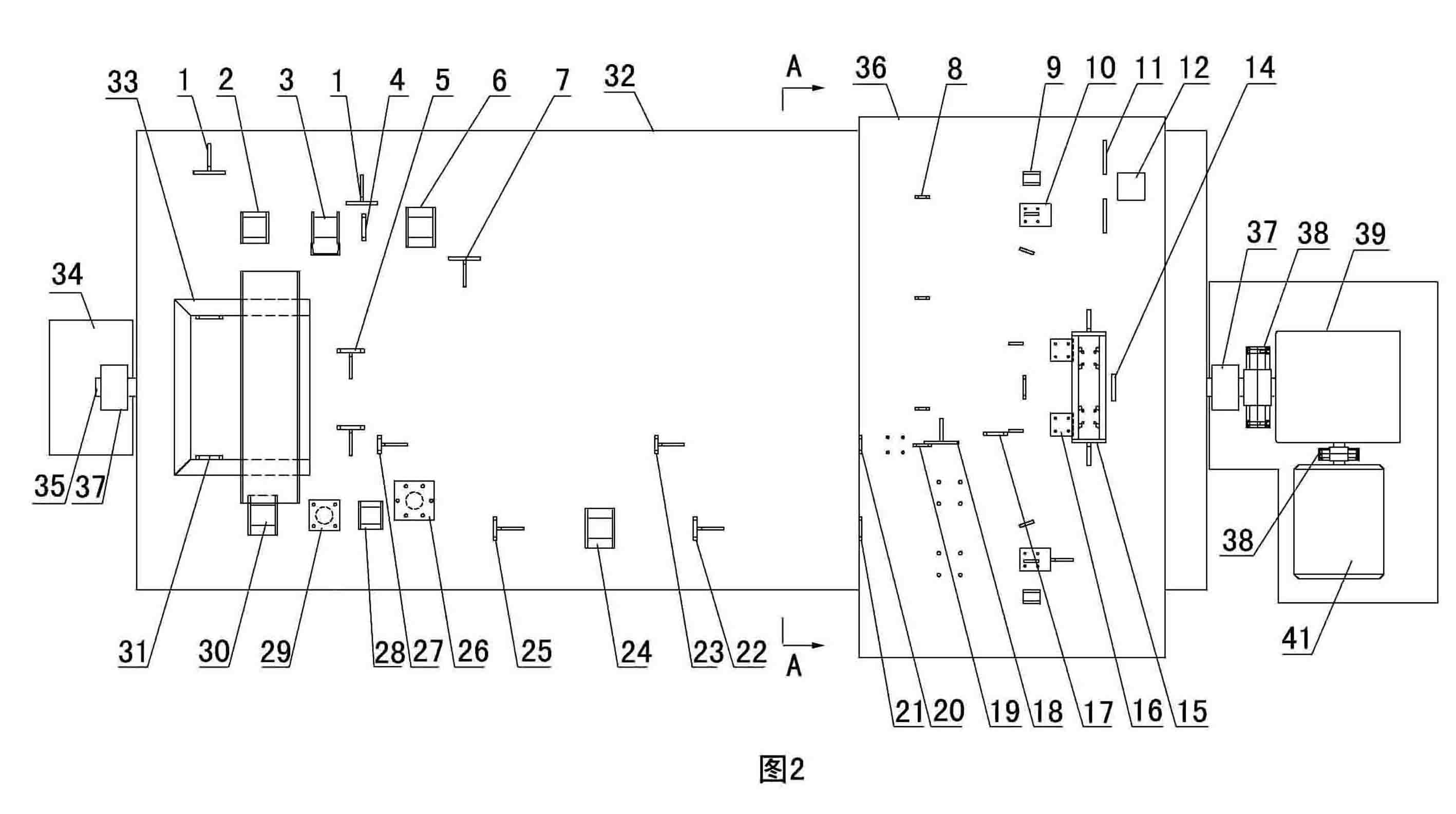

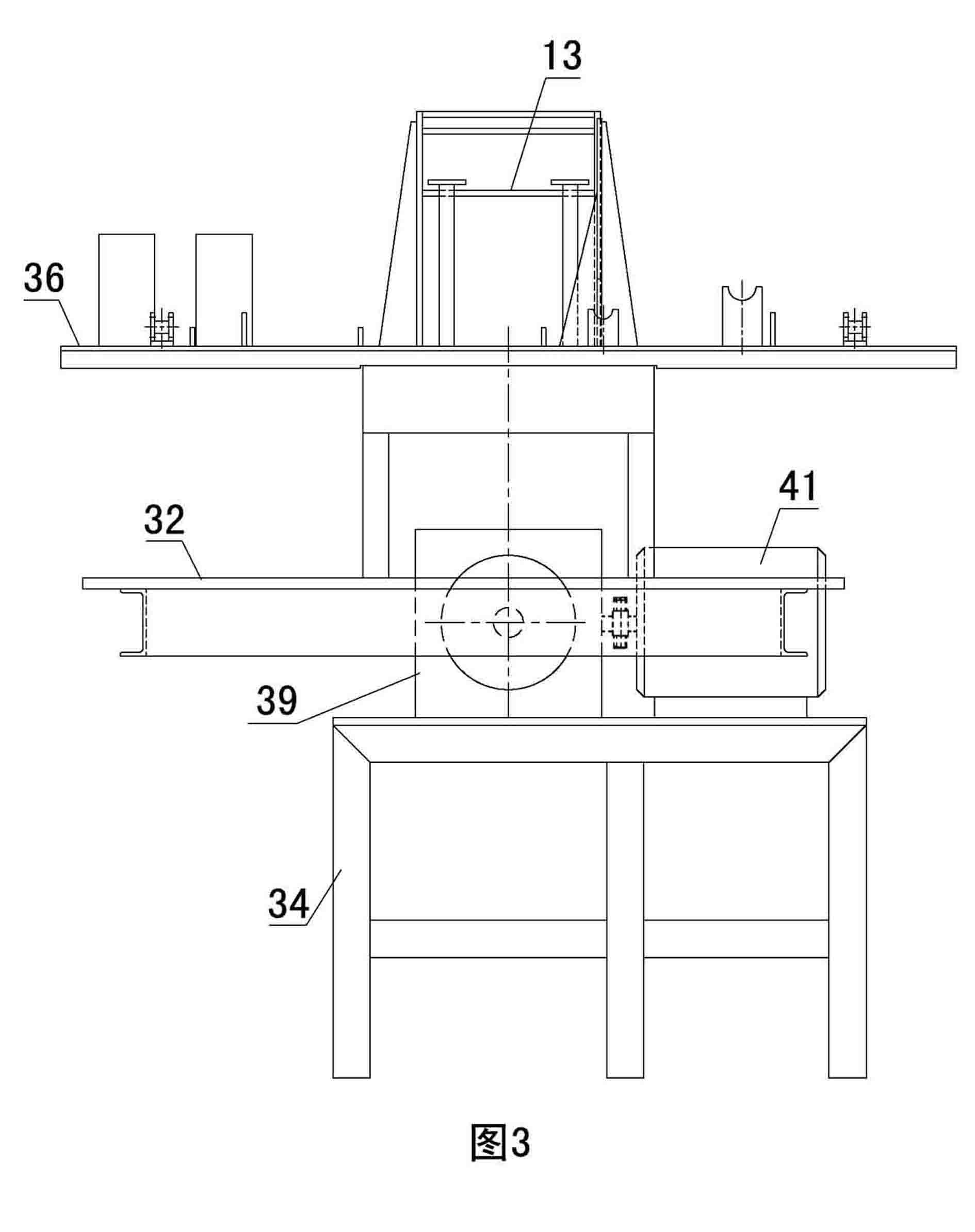

[0027] Examples see Figure 1-3 As shown, this pipeline forming welding system is composed of welding equipment and oil circuit tooling, wherein the oil circuit tooling includes two basic platform support frames 34 and a basic platform 32 connected between the two basic platform support frames , the left and right ends of the base platform 32 are fixedly connected with a horizontal shaft 35, and the horizontal shaft 35 is rotatably supported on the base platform support frame 34 through a shaft seat 37, and is also fixedly placed on one of the two base platform support frames 34. There is a motor 41, the output end of the motor 41 is connected with the input end of the speed reducer 39 through a shaft coupling, and the output end of the speed reducer 39 is connected with the horizontal rotating shaft 35 through a shaft coupling. The basic platform is a support platform for the oil pipeline at the lower part of the tank body.

[0028] A positioning device and a pipeline suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com