Support system of rear support removing type section steel-concrete double-enclosing-purlin foundation pit and construction method

A technology of support system and construction method, applied in basic structure engineering, excavation, construction, etc., can solve problems such as affecting construction progress and construction quality, structural construction can not work continuously, poor integrity of structural steel skeleton, etc., to achieve convenient construction process, The effect of good economic benefits and reliable construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

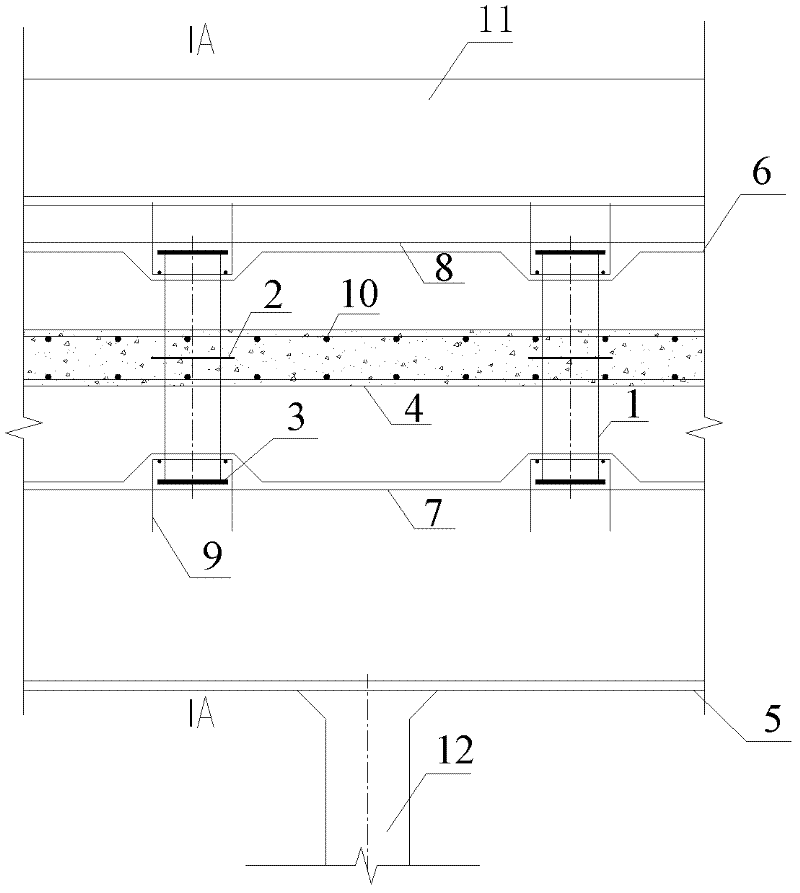

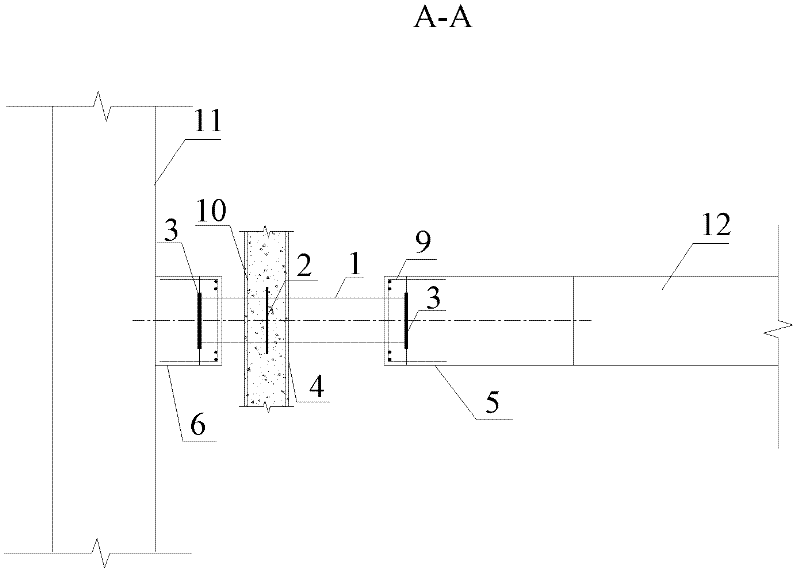

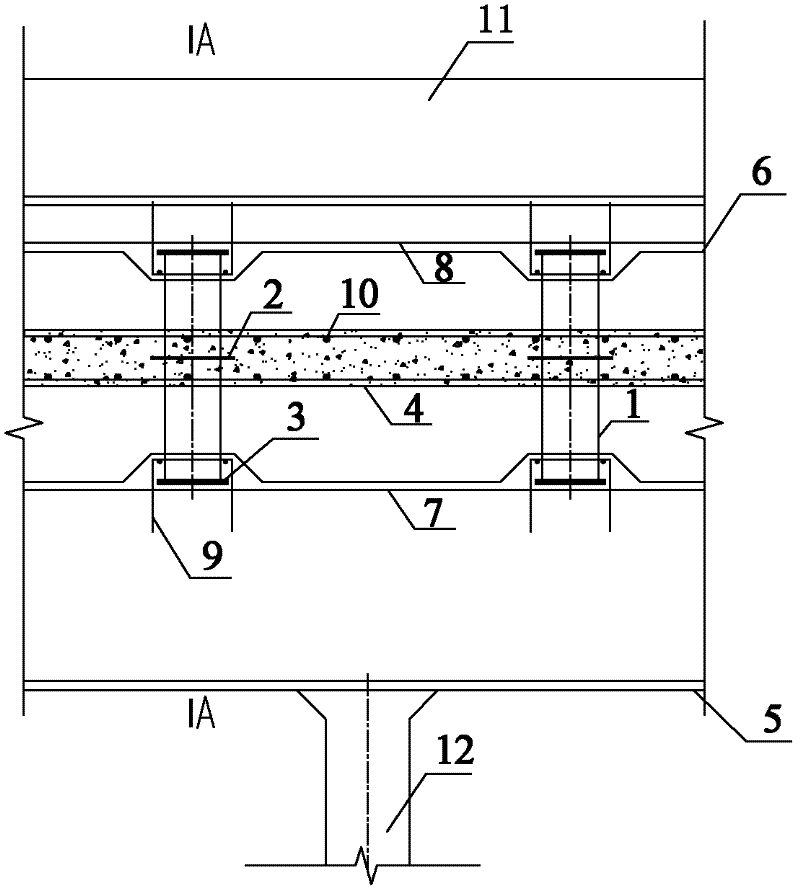

[0025] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] see figure 1 , figure 2 The shown one kind of post-detachable type steel-reinforced concrete double wall purlin support system includes a wall (pile) 11 located in the foundation pit, a plurality of horizontal supports 12 located inside the wall 11, fixed on the wall The reinforced concrete purlin 6 on the parapet wall 11, the reinforced concrete purlin 5 fixed on the horizontal support 12, a plurality of horizontally arranged section steels 1, the purlin 6 and the horizontal support 12 evenly arranged on the side of the parapet wall 11 Between the purlins 5 on the side, as the force transmission path between the purlins 5 and 6 on both sides; a plurality of vertical steel bars 10 pass from the bottom to the top between the section steel 1 and the purlins 5 and 6; The structural wall 4 connecting the vertical steel bars 10 . It also includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com