Foundation pit containment structure with prestress ribs on vertical soil-retaining structure and construction method

A technology of retaining structures and prestressed tendons, which is applied in the direction of foundation structure engineering, excavation, and sheet pile walls, etc., can solve the problems that prestressed tendons cannot be recycled, are not suitable for foundation pits, and are not applicable, so as to reduce settlement and resist Effects of improved bending stiffness, durability and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

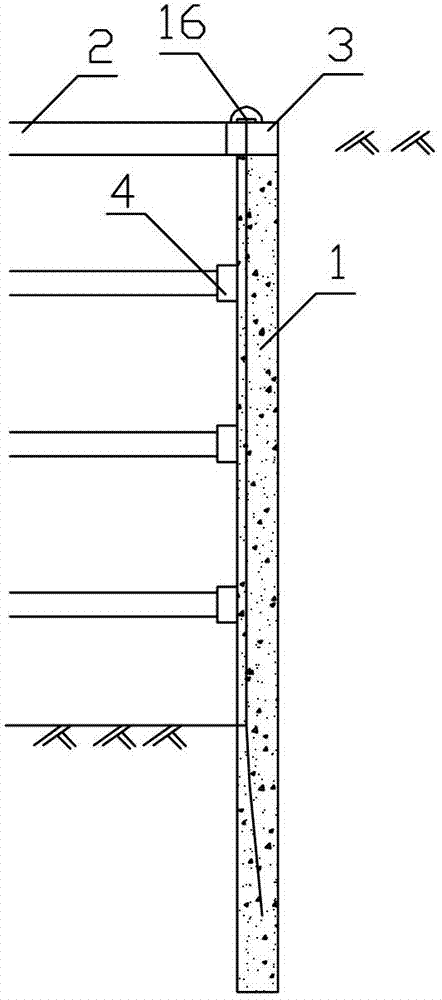

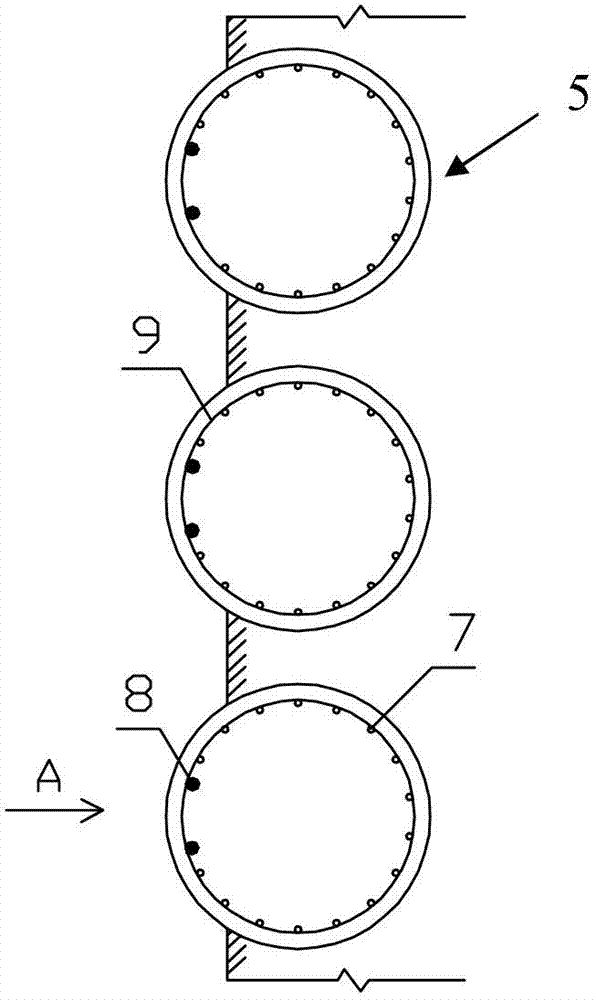

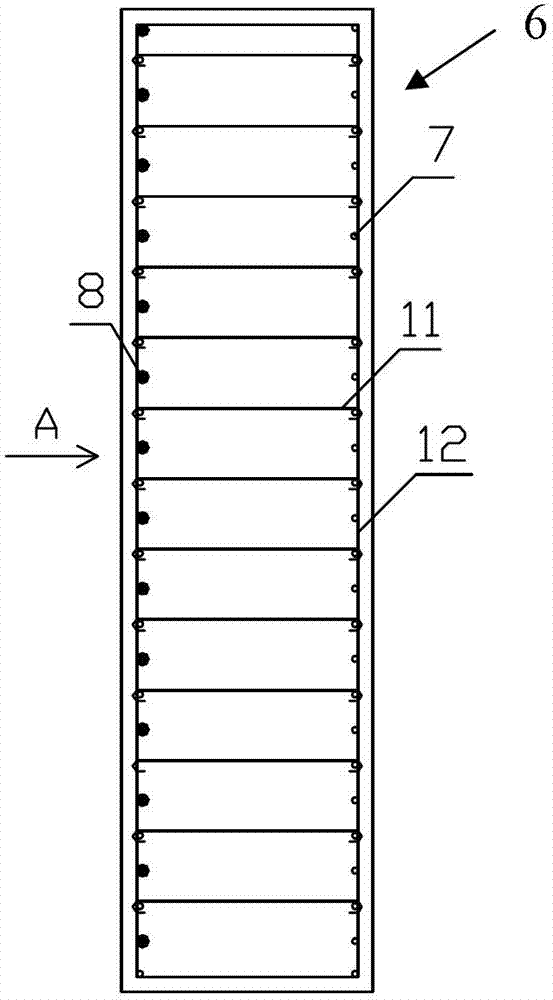

[0033] The foundation pit enclosure structure provided with prestressed tendons on the vertical soil retaining structure provided by the present invention and the construction method will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] Such as Figure 1-Figure 6 As shown, the foundation pit enclosure structure equipped with prestressed tendons on the vertical retaining structure provided by the present invention includes a vertical retaining structure 1, multiple horizontal supports 2, reinforced concrete ring beams 3 and multiple purlins 4; The vertical retaining structure 1 is arranged on the inner edge of the foundation pit, which is composed of a plurality of drilled concrete piles 5 or concrete continuous walls 6 arranged at intervals; the reinforced concrete ring beam 3 is arranged on the top of the vertical retaining structure 1 ; Multiple purlins 4 are arranged on the inner peripheral surface of the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com