Measurement, control and construction method for curved roof formwork system

A construction method and curved surface technology, applied in formwork/formwork/work frame, roof, building components, etc., can solve problems affecting the construction quality of curved concrete roofs, inaccurate curved roof formwork systems, and inaccurate positioning. Achieve the effects of reducing the difficulty and labor intensity of surveying and placing, ensuring construction quality and accurate elevation positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is further described in conjunction with the following examples.

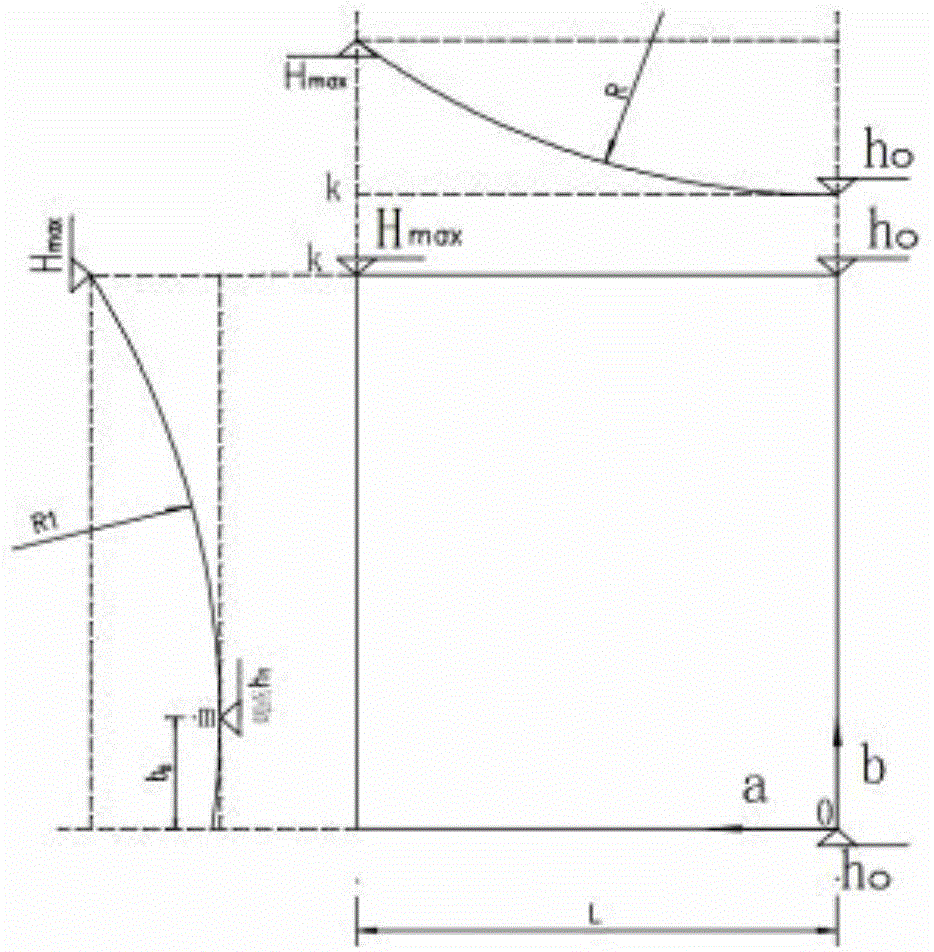

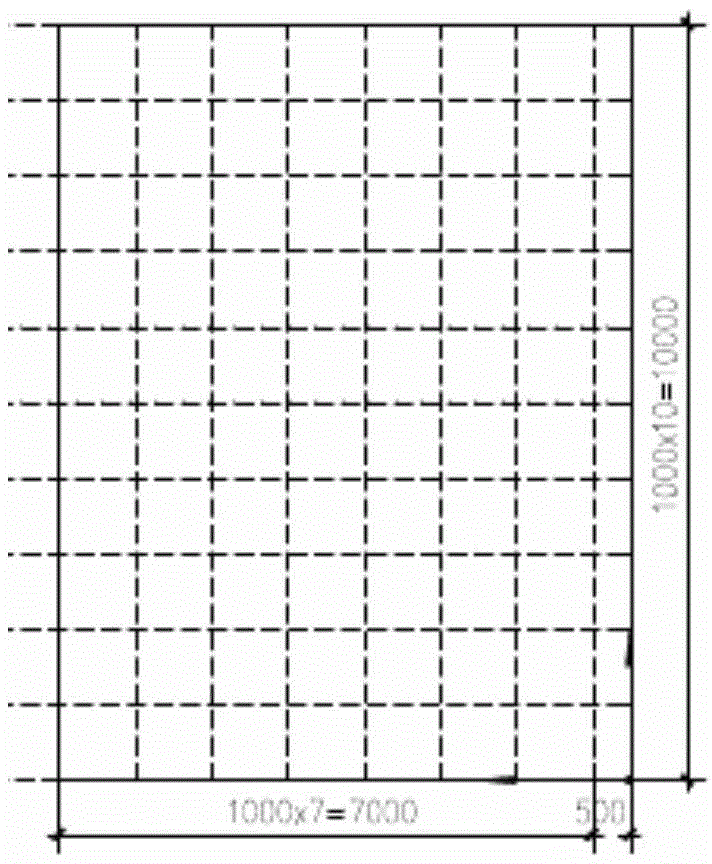

[0040] The roof measurement and control construction method created by the invention needs to quickly and accurately measure the axis elevation of the curved surface of the curved concrete roof before building the construction bottom formwork. The invention uses the coordinate grid measurement and positioning method to project the spatial curved surface horizontally. The axis elevation measurement specifically includes the following steps:

[0041] A. Curved concrete roof such as figure 1As shown, by using the finite element analysis software, it is projected in three directions, namely projecting the curved concrete roof to the horizontal plane along the vertical direction, projecting the curved concrete roof to the rear and projecting the curved concrete roof to the left side projection.

[0042] B. The curved concrete roof is projected on the horizontal plane to form the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com