Design method of airplane frame and rib type sheet metal part processing model

A technology of process model and sheet metal parts, which is applied in the field of process model design of aircraft frame and rib sheet metal parts, and can solve the problems of small number of single pieces of frame and rib parts, large size changes, and difficulty in parametric expression of structural features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

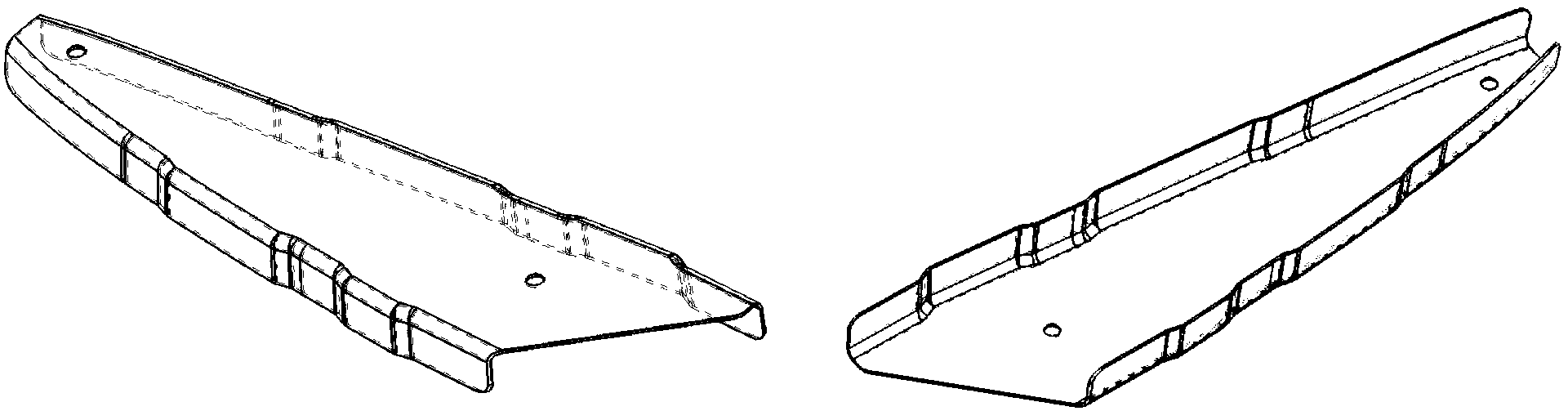

[0053] by figure 1 Example Take the 20-rib part of the front flap as an example. The part consists of a flat web and two flanges with variable curvature, sagging and stringer notches. Combined with the accompanying drawings, the specific implementation process of the process model design method for aircraft frame rib parts is described.

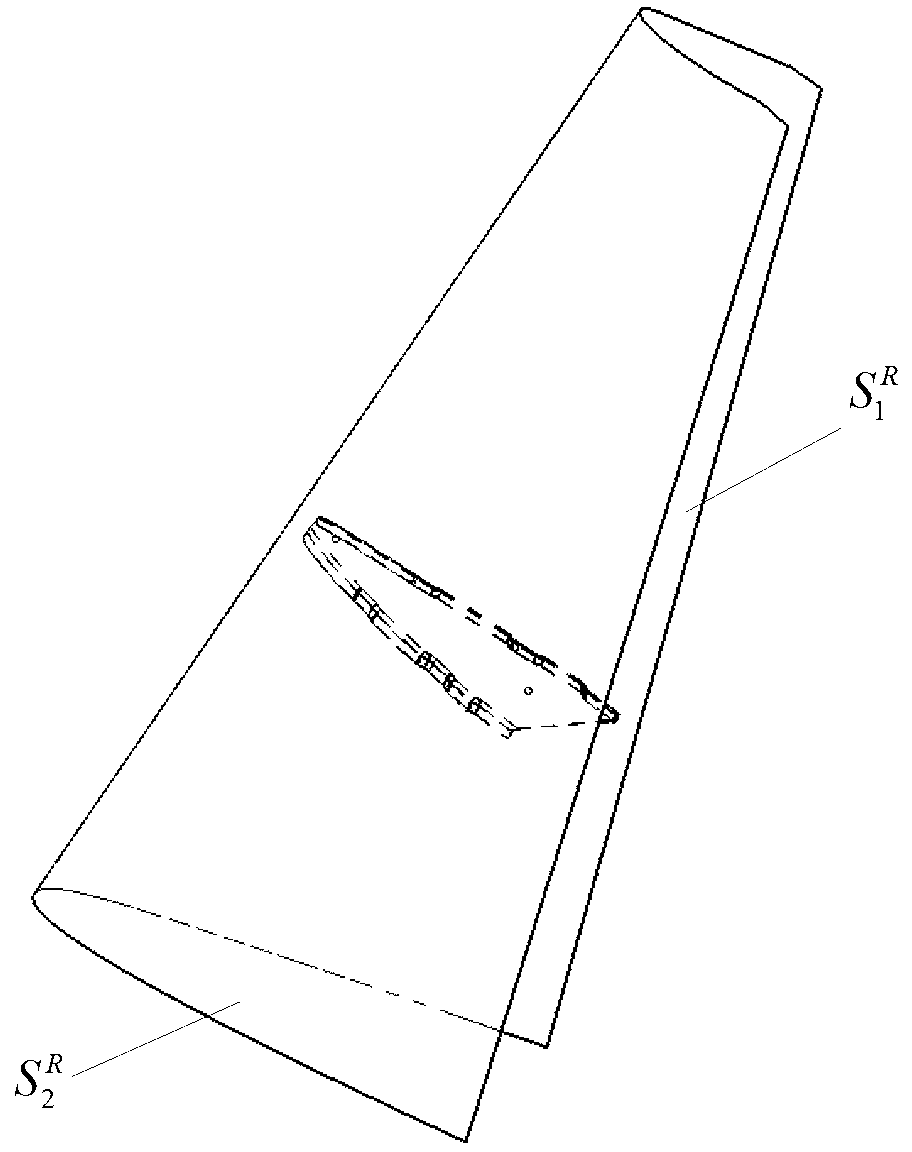

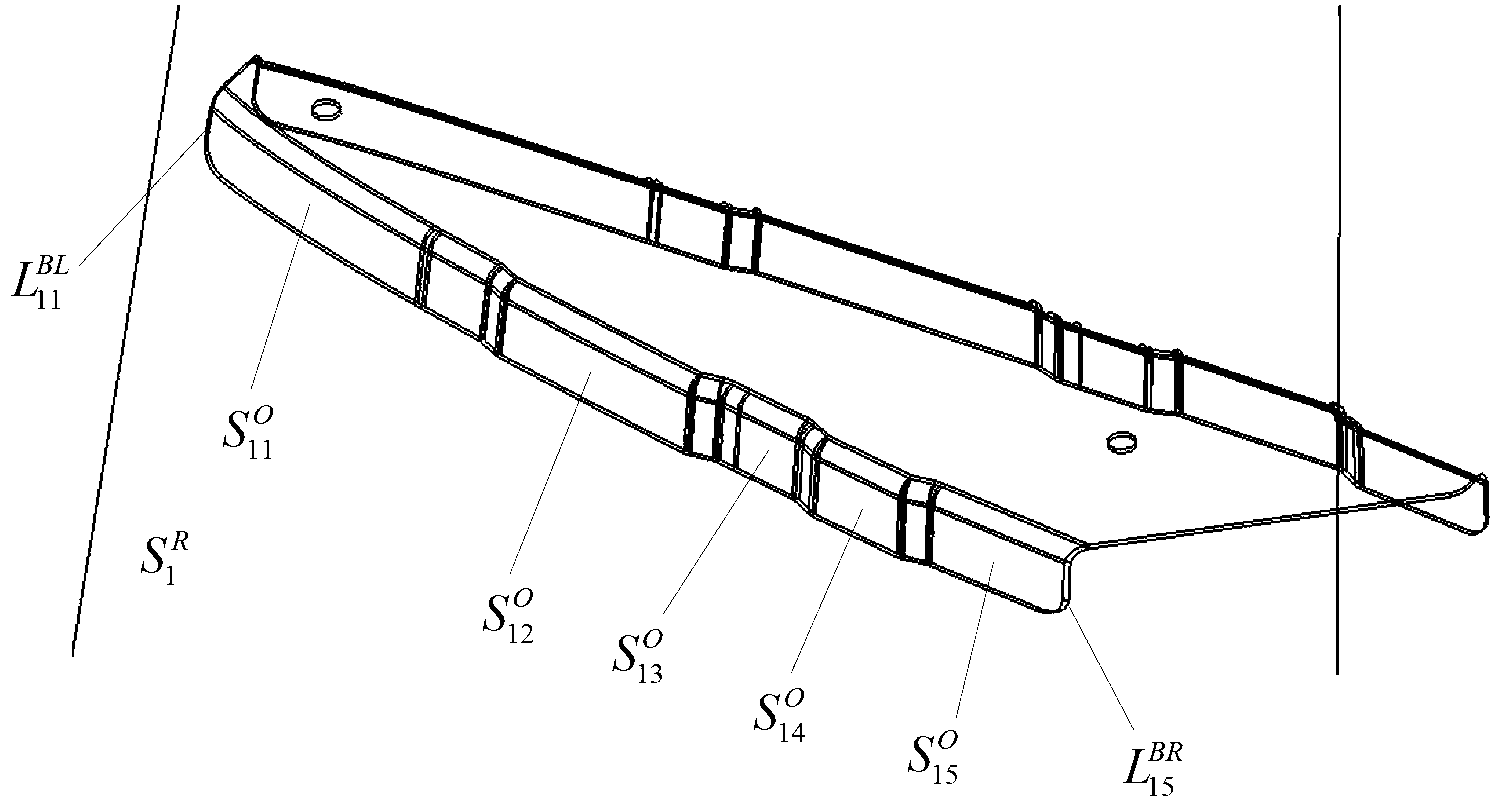

[0054] 1. Example parts are figure 2 The 2 flange design reference surfaces shown and image 3 Flange outer surface shown by as design basis; use plane F WU and F WD intercept get Figure 4 Flange split reference plane shown borderline and projection line and in the normal plane and between, and intercept Get Flange Projection Segmentation Extended Reference Surface and common intercept plane F WU Get web extension inner surface The result is as Figure 5 Shown; the radius of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com