Long-span pre-stress fish belly sill for foundation pit support and mounting method thereof

A foundation pit support and installation method technology, applied in excavation, foundation structure engineering, construction, etc., can solve the problems of small span, low rigidity of steel purlins, inconvenient connection, etc., and achieve large span, shortened construction period, and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

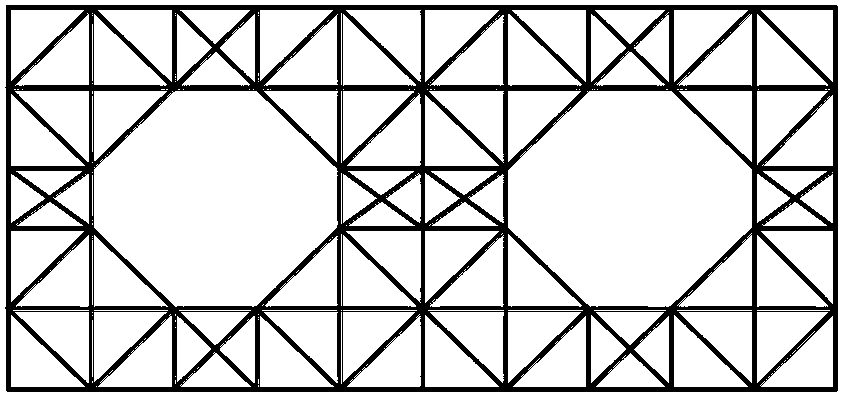

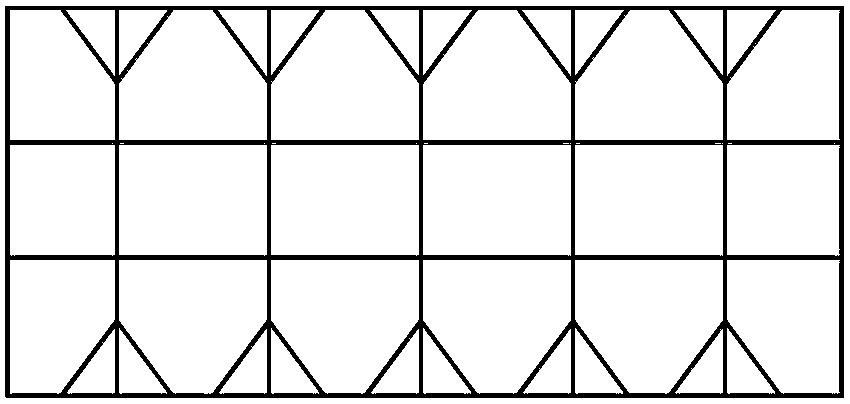

Image

Examples

Embodiment Construction

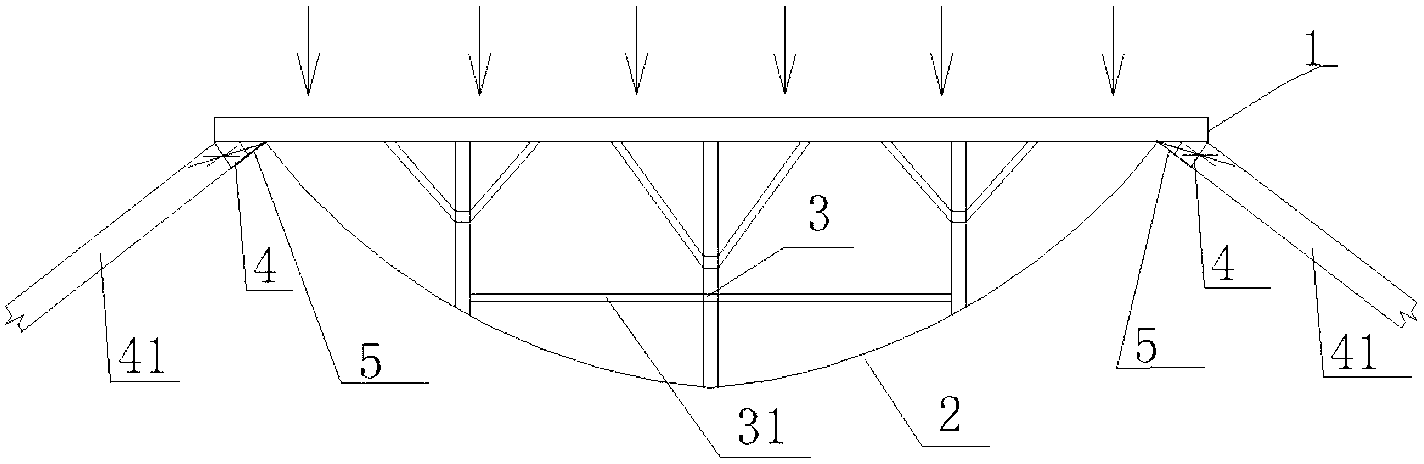

[0046] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0047] see image 3 , the long-span prestressed fish-belly girder structure, including a lower chord beam 1, steel strand 2, web bar 3, two support points 4 for purlins, and special anchorage 5.

[0048] Its lower string beam 1 is assembled from section steel materials; its steel strand 2 is composed of multiple high-strength and low-relaxation steel wires, and each steel strand is covered with a plastic tube and filled with grease for protection and isolation;

[0049] Its web bar 3 is assembled from section steel materials into a wooden or straight shape; its supporting point 4 is assembled from section steel materials into a triangle; its prestressed loading locking mechanism is composed of special anchors 5 .

[0050] The web bar 3 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com