Truss and purlin support apparatus and a method of making and using same with building supports and floor and roof sheathing

a technology of support apparatus and purlin, which is applied in the direction of load-supporting elements, structural elements, building components, etc., can solve the problems of prior art systems that included, costly in terms of material costs, and -channel joists

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

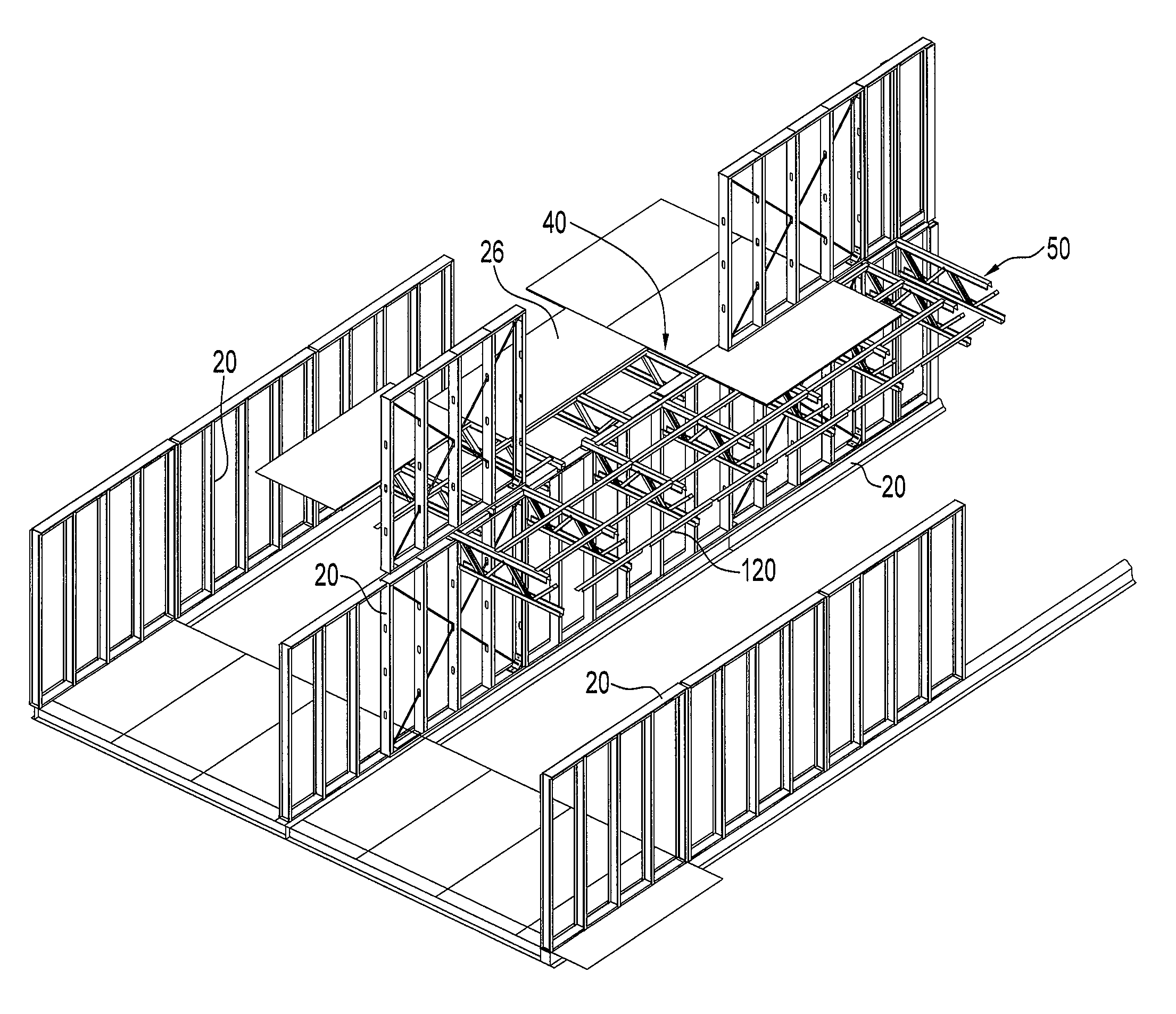

[0069] A truss and purlin support apparatus 40 according to the invention in shown in FIG. 3 of the drawings in use with building support members 20 and substantially planar substrate sheathing members 26. The apparatus 40 includes a plurality of Pratt-style elongate truss members 50 and a plurality of purlin members 120.

[0070] Each of the truss members 50 has at least two support portions 52 longitudinally spaced from one another. The support portions 52 are adapted to operatively engage and transfer loads to the building support members 20.

[0071] Each of the truss members 50 includes an elongate top chord 54b, an elongate bottom chord 54a, and a plurality of web members 80 securely extending between the top chord 54b and the bottom chord 54a. The top chord 54b, the bottom chord 54a, the web members 80, and the purlin members 120 are preferably constructed from roll-formed light gauge steel material. Each top chord 54b and each bottom chord 54a may preferably, but need not necess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com