Connection structures between foundation pit support piles and outer walls of basement and construction method

A support technology for basement exterior walls and foundation pits, which is applied to foundation structure engineering, underwater structures, artificial islands, etc., can solve the problems of large number of anti-buoyancy piles, high cost, and high construction labor intensity, and achieve saving A large amount of cost, avoiding floating damage, and simplifying the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

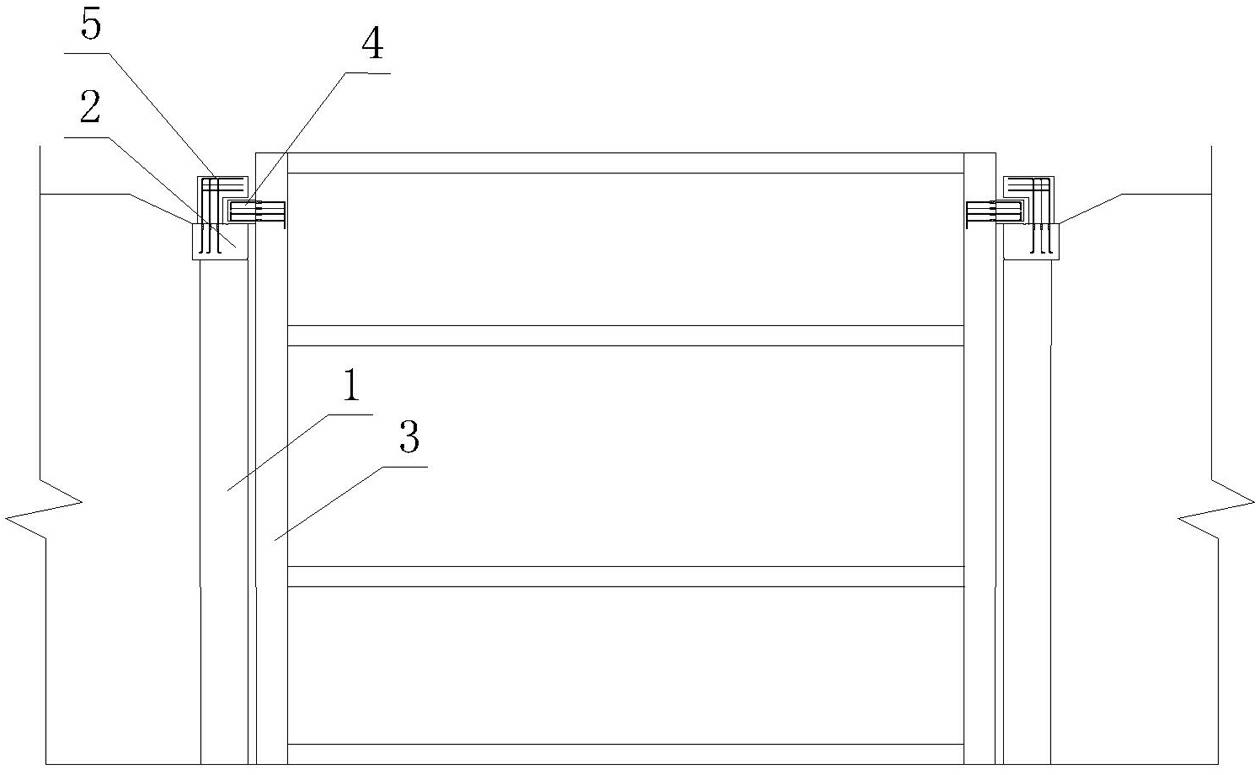

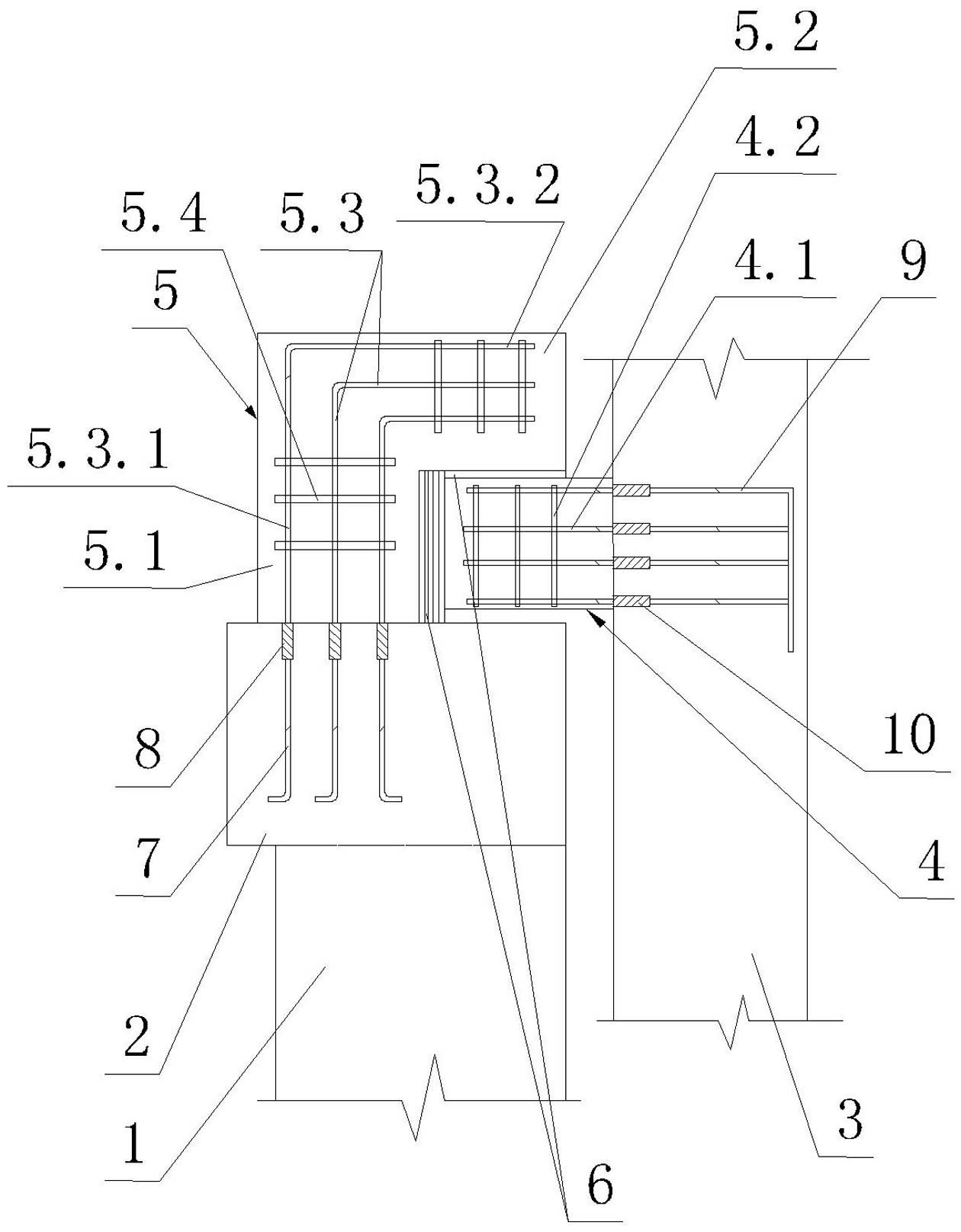

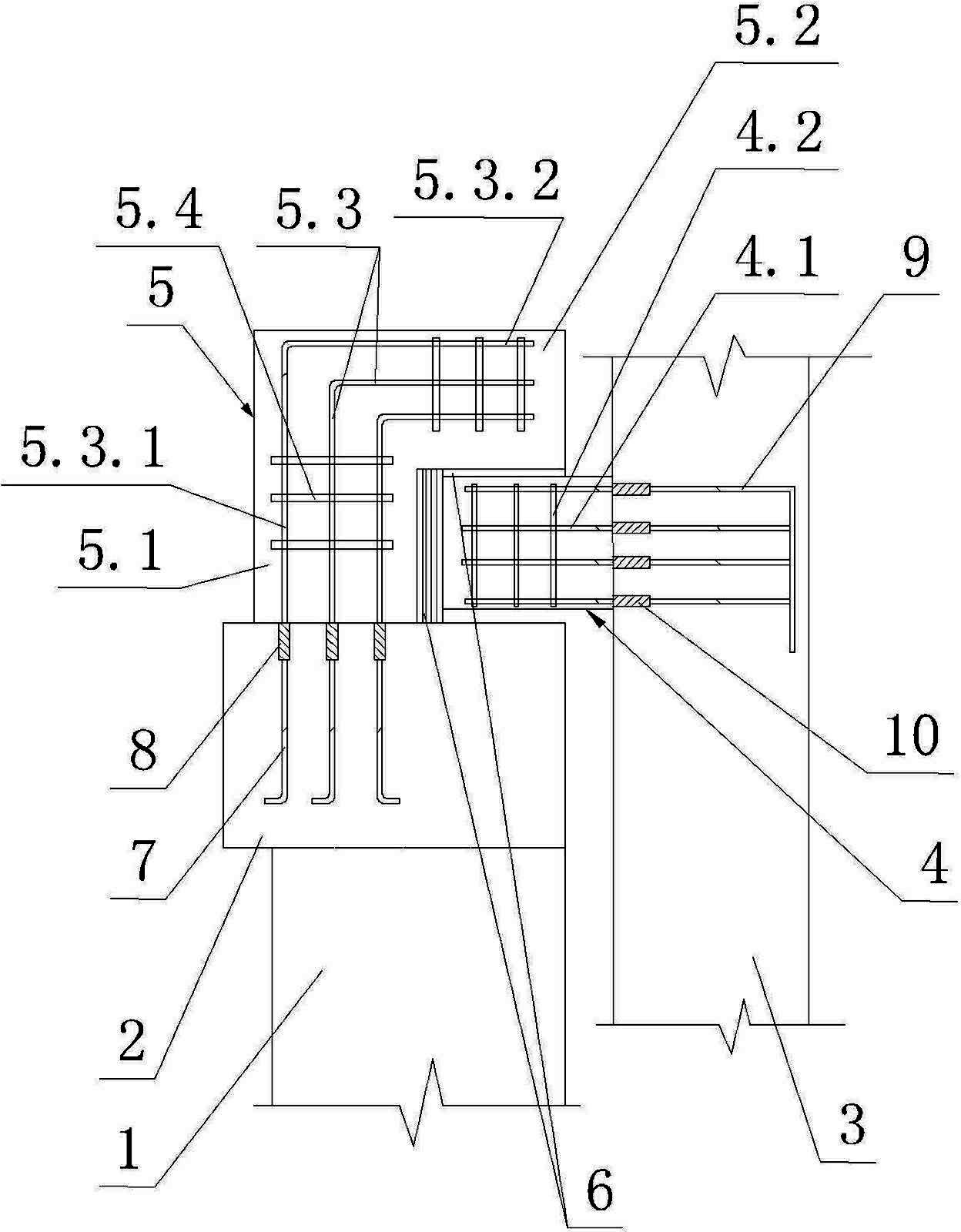

[0032] Such as figure 1 , figure 2 As shown, the connection structure between the foundation pit support pile and the basement outer wall of the present invention includes a crown beam 2 and a basement outer wall 3 positioned at the top of the foundation pit support pile 1 . Concrete corbels 4 protrude from the outer surface of the basement exterior wall 3 , the bottom surface of the concrete corbel 4 is higher than the top surface of the crown beam 2 , and the outer end of the concrete corbel 4 is located above the crown beam 2 . The top surface of the crown beam 2 is provided with a concrete capping beam 5, which is composed of an integrated column 5.1 and a beam 5.2. Concrete pressure beam 5.

[0033]The beam 5.2 is pressed on the top surface of the concrete corbel 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com