Supporting system reinforcement structure after foundation pit deepening

A technology for strengthening structures and foundation pits, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of reducing the amount of engineering, increasing the amount of engineering, refilling, etc., and achieves the effect of reducing construction costs and reducing the amount of engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

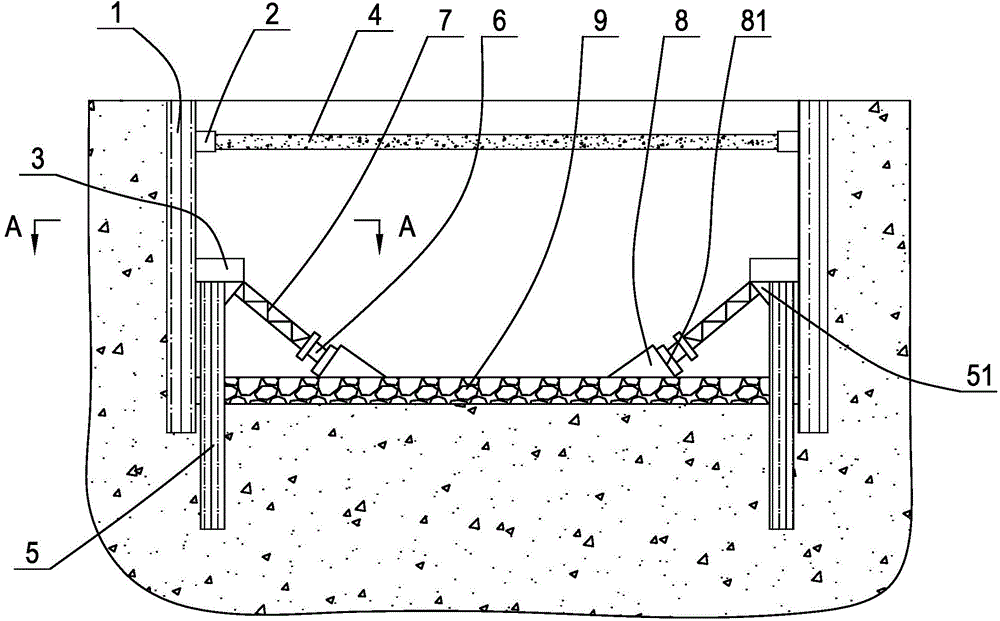

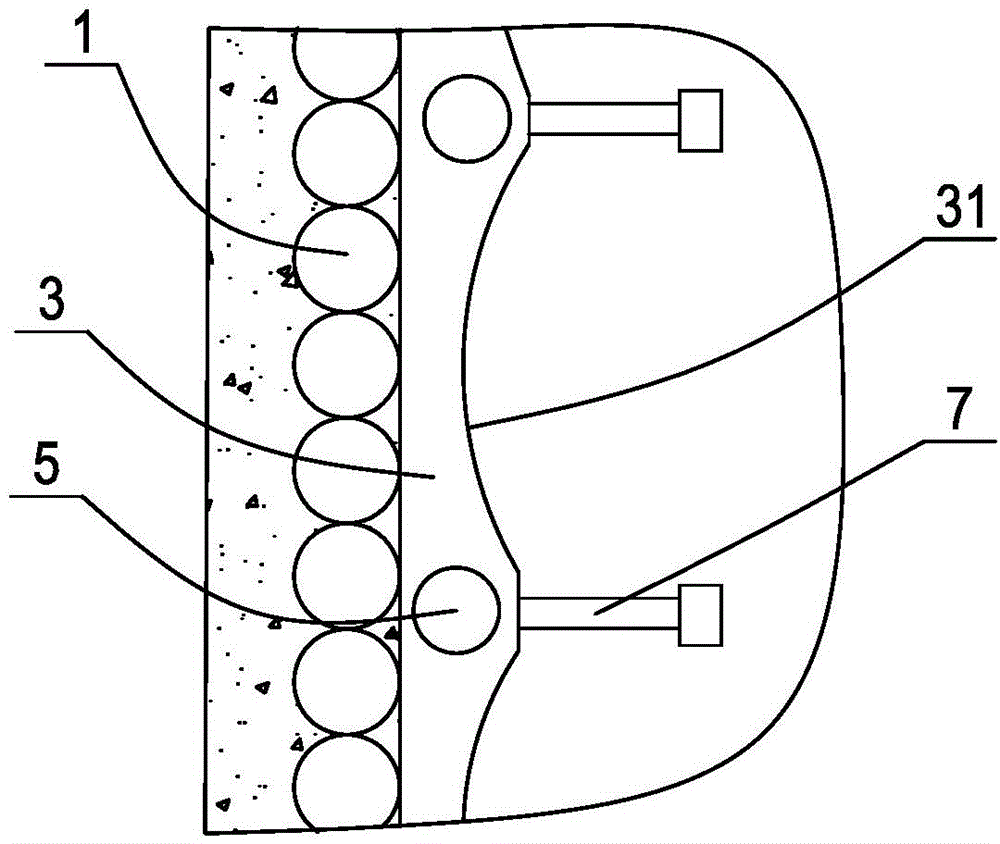

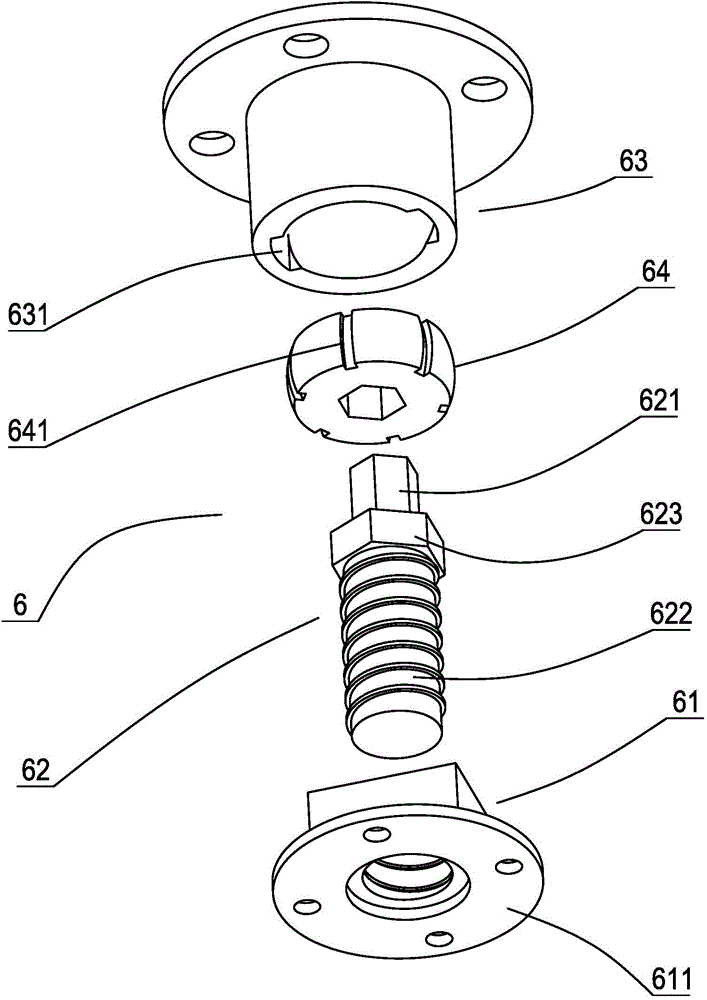

[0031] Such as figure 1 , figure 2As shown in Fig. 1, a reinforced structure of the support system after the foundation pit is deepened. The reinforcement includes cast-in-situ piles 1 arranged around the edge of the foundation pit. The cast-in-place piles can be formed by pouring concrete after drilling, or by using existing technologies such as SMW piles. In addition, a horizontal first purlin girder 2 is arranged inside the upper end of the cast-in-place pile so as to connect the cast-in-place piles into one body. Then connect the horizontal support beam 4 between the first purlin girders on the relatively long opposite sides of the foundation pit. The horizontal support beam can be a reinforced concrete beam or a steel structure beam made of section steel such as I-beam or H-beam. Of course, the depth of the cast-in-place piles is desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com