Space robot paw

A technology of space robots and grippers, applied in the field of robotics, can solve the problems of small capture range of grippers, easy loss of targets, and non-unique determination of the final grasping position, etc., and achieve the effect of flexible rotary motion, fast movement, and large deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

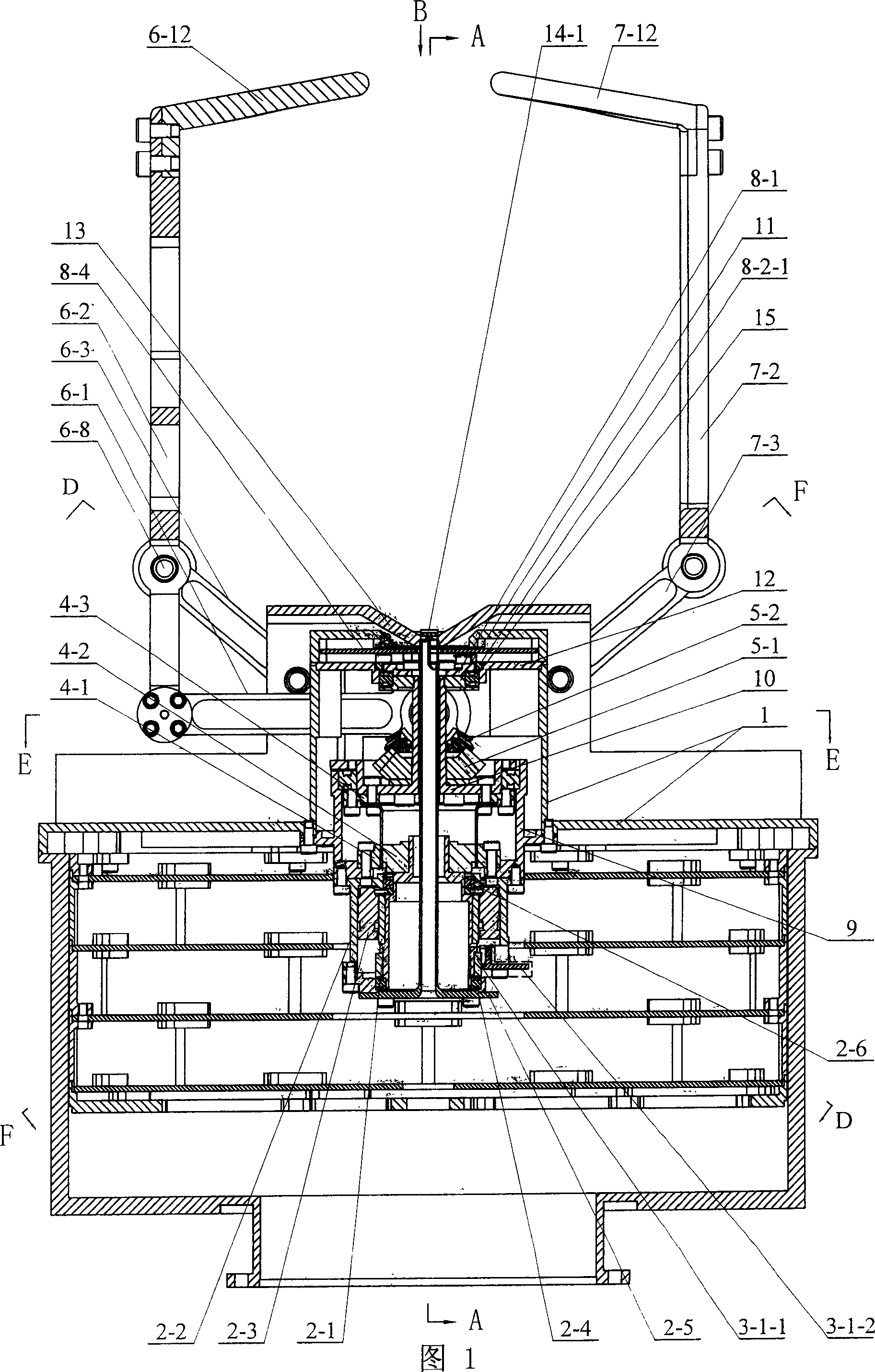

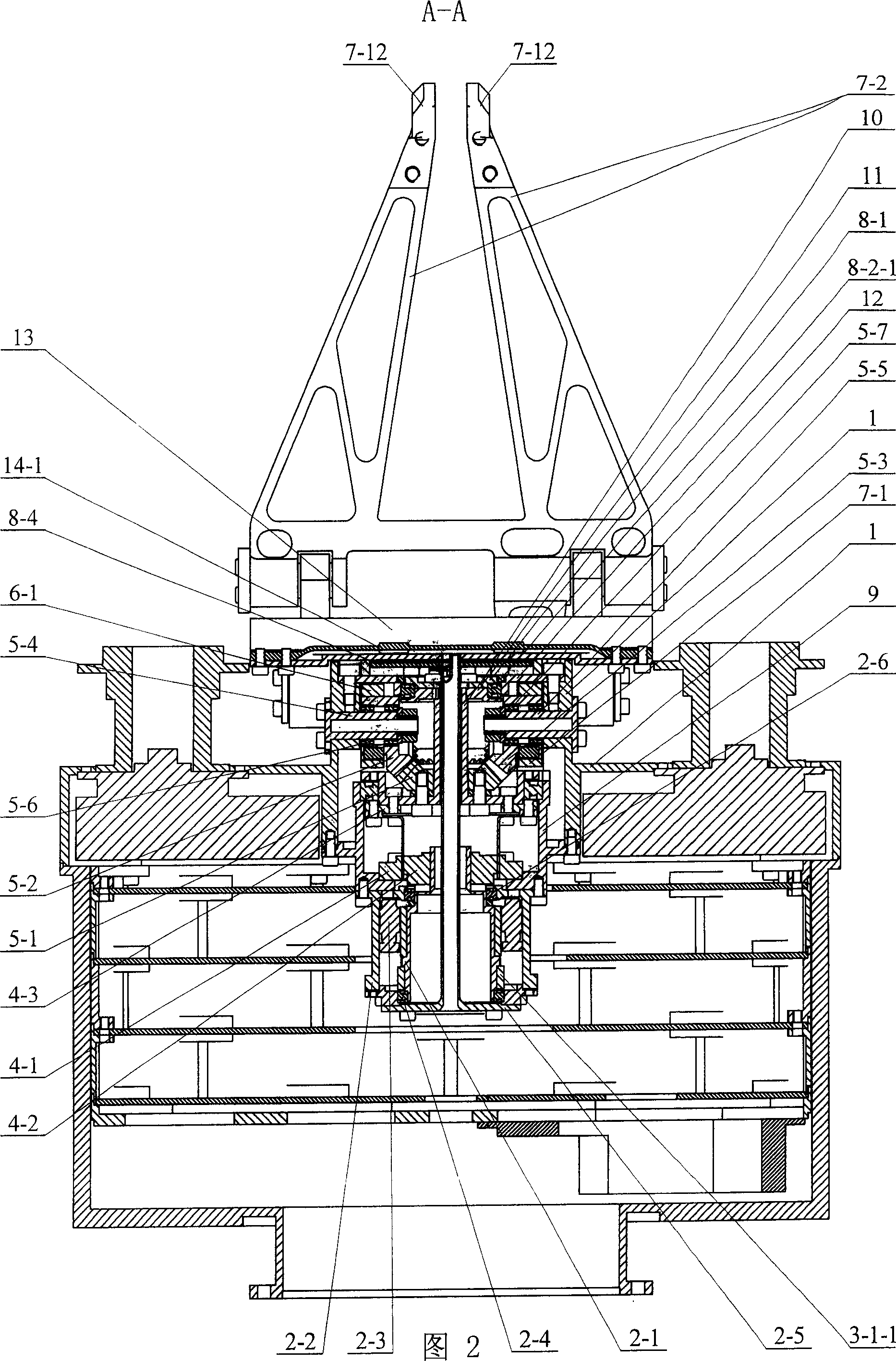

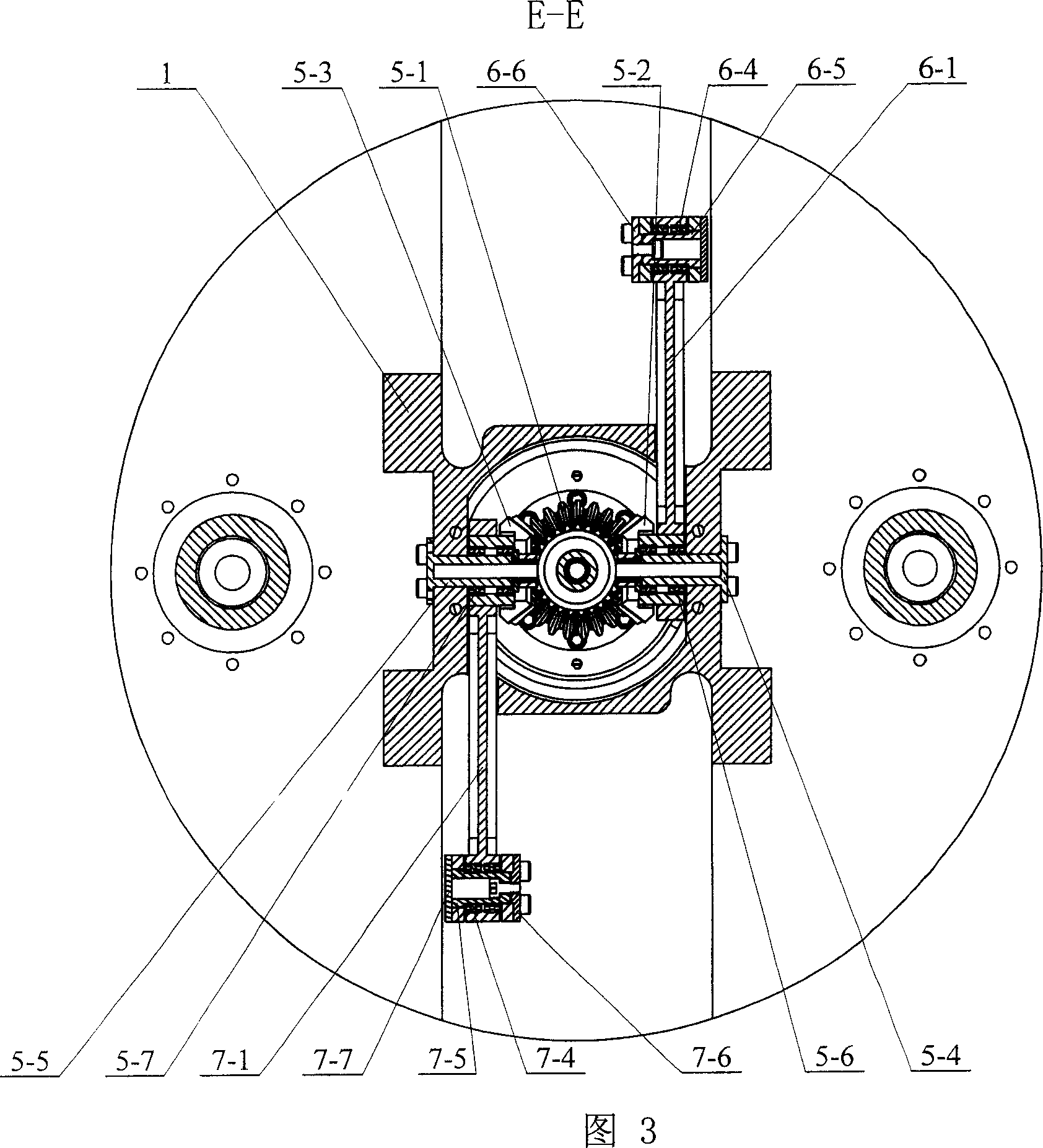

[0006] Specific embodiment 1: This embodiment is described in conjunction with Fig. 1, Fig. 2, Fig. 5, and Fig. 7. This embodiment consists of a housing 1, a motor drive device, a motor position sensor, a harmonic reducer component, a gear transmission, Link mechanism, two-finger four-link mechanism, finger position sensor, support sleeve 9, drive flange 10, shaft end flange 11, end cover plate 12, V-shaped positioning groove 13, contact sensor; the motor position sensor The magnetic ring 3-1-1 is fixedly installed on the motor shaft 2-1 in the motor drive device, the motor casing 2-2 in the motor drive device is fixedly connected with the support sleeve 9, and the support sleeve 9 is connected with the harmonic reducer parts The rigid wheel 4-1 is fixedly connected, the wave generator 4-2 in the harmonic reducer part is fixedly mounted on the motor shaft 2-1, and the flexible spline ring 4-3 in the harmonic reducer part is fixed to the drive flange 10 connection, the driving ...

specific Embodiment approach 2

[0008] Specific embodiment two: this embodiment is described in conjunction with Fig. 1, Fig. 2, the motor position sensor of this embodiment is made up of magnetic encoder and the inherent digital hall element of motor itself; Magnetic encoder is made up of magnetic ring 3-1-1, The magnetic ring detection circuit is composed of 3-1-2; Connect the magnetic ring detection circuit 3-1-2. The motor position sensor is used, and the motor position detection system is composed of a magnetic encoder and a digital hall element inherent in the motor itself. The magnetic ring detection circuit 3-1-2 is installed on the motor shell 2-2 to record the rotation position of the motor. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific Embodiment Three: This embodiment is described in conjunction with Fig. 1 and Fig. 2. The motor driving device of this embodiment is a DC brushless motor; the DC brushless motor consists of a motor shaft 2-1, a motor casing 2-2, The stator 2-3, the first motor bearing 2-4, the bearing cover 2-5, and the second motor bearing 2-6 are composed; the motor stator 2-3 is fixedly connected with the motor casing 2-2, and the motor stator 2-3 is equipped with a motor Rotating shaft 2-1, the first motor bearing 2-4 is housed between the motor rotating shaft 2-1 and the motor casing 2-2, the first motor bearing 2-4 is positioned by the bearing cover 2-5, and the bearing cover 2-5 is connected with the motor The casing 2-2 is fixedly connected, the second motor bearing 2-6 is installed between the motor rotating shaft 2-1 and the motor casing 2-2, and the motor casing 2-2 is fixedly connected with the support sleeve 9. It adopts DC brushless motor to facilitate its control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com