liquid composition sensor

A sensor and liquid technology, applied in the direction of instruments, scientific instruments, analytical materials, etc., can solve the problem of detection accuracy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An optical liquid composition sensor according to an example embodiment is used to detect a composition and a concentration of the composition in a liquid. For example, when gasoline and alcohol such as ethanol are mixed into a mixed fuel, the sensor is used as a fuel characteristic sensor for detecting alcohol, water, and acetic acid in gasoline.

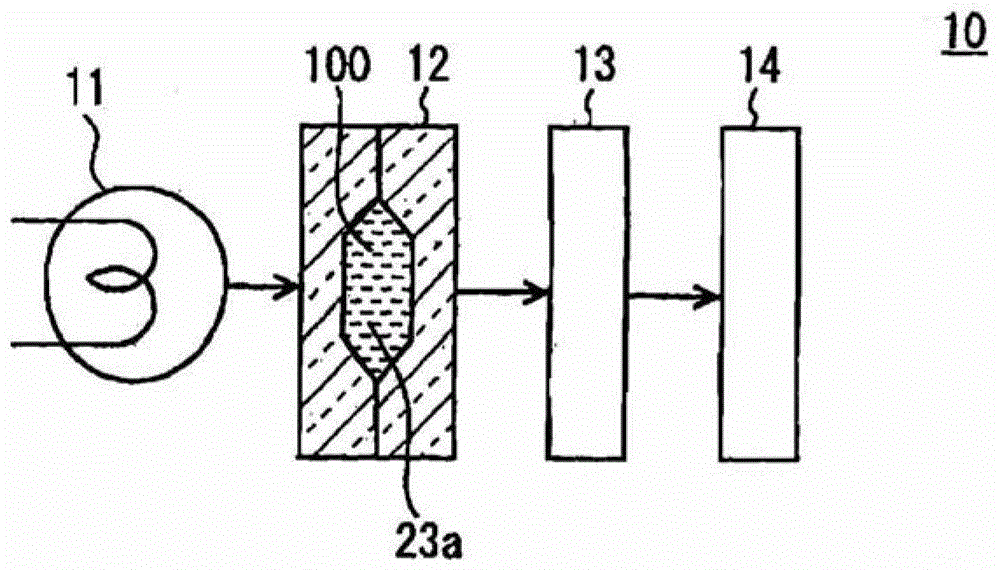

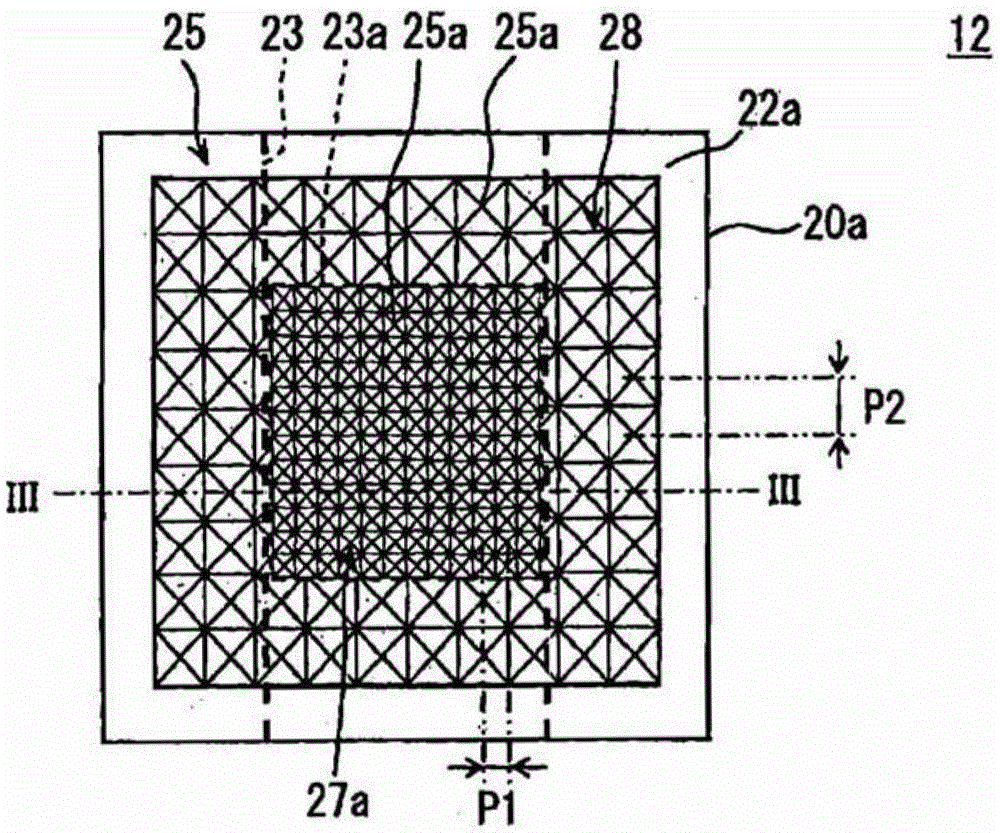

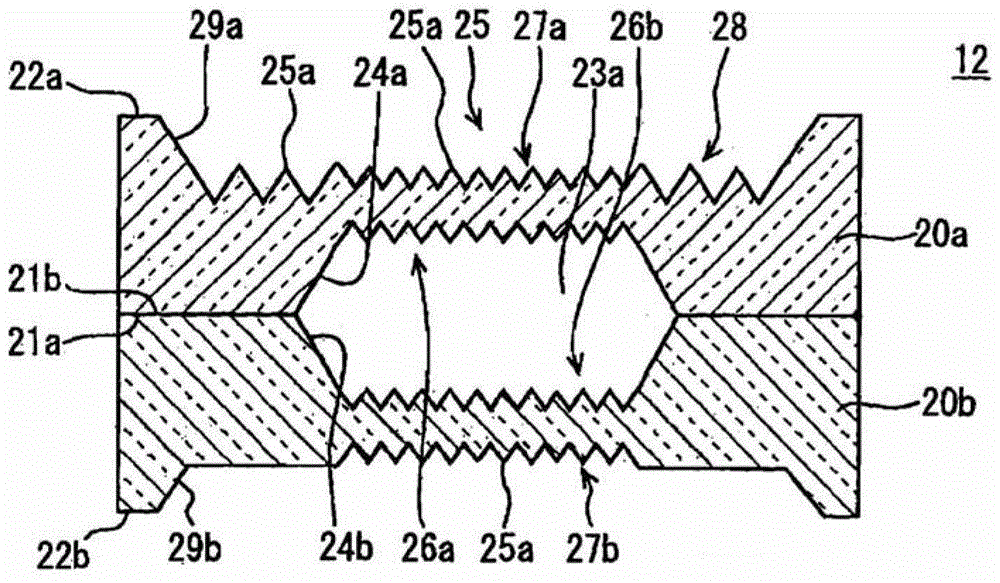

[0026] like figure 1 As shown, the liquid composition sensor 10 includes a light source 11 , a detection unit 12 , a spectrometer 13 and a light detector 14 . Reference numeral 100 denotes a liquid. The detection unit has a specific structure. The configuration other than the detection unit will be described below.

[0027] The light source 11 outputs infrared light. The light source 11 corresponds to an infrared light source. Here, the light source for outputting infrared light may radiate light including infrared light in a specific wavelength band. Thus, the light source may only output infrared light. Alternativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com