An installation method for a curved steel reticulated shell structure with a gradual change in the starting span of the gable wall

An installation method and starting span technology, applied in building structure, building material processing, construction, etc., can solve the problems of difficulty in controlling the positioning accuracy of the inner ball, complex structural load and deflection, and difficulty in effectively maintaining verticality, etc., to achieve It is easy to adjust the accuracy error, increase the construction safety performance, and ensure the effect of pulling and setting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

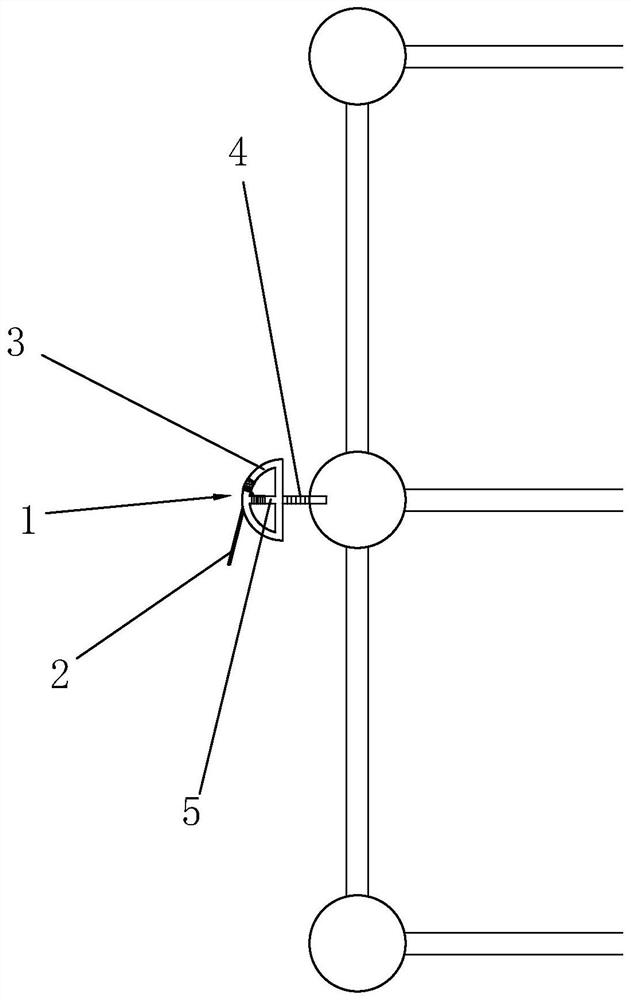

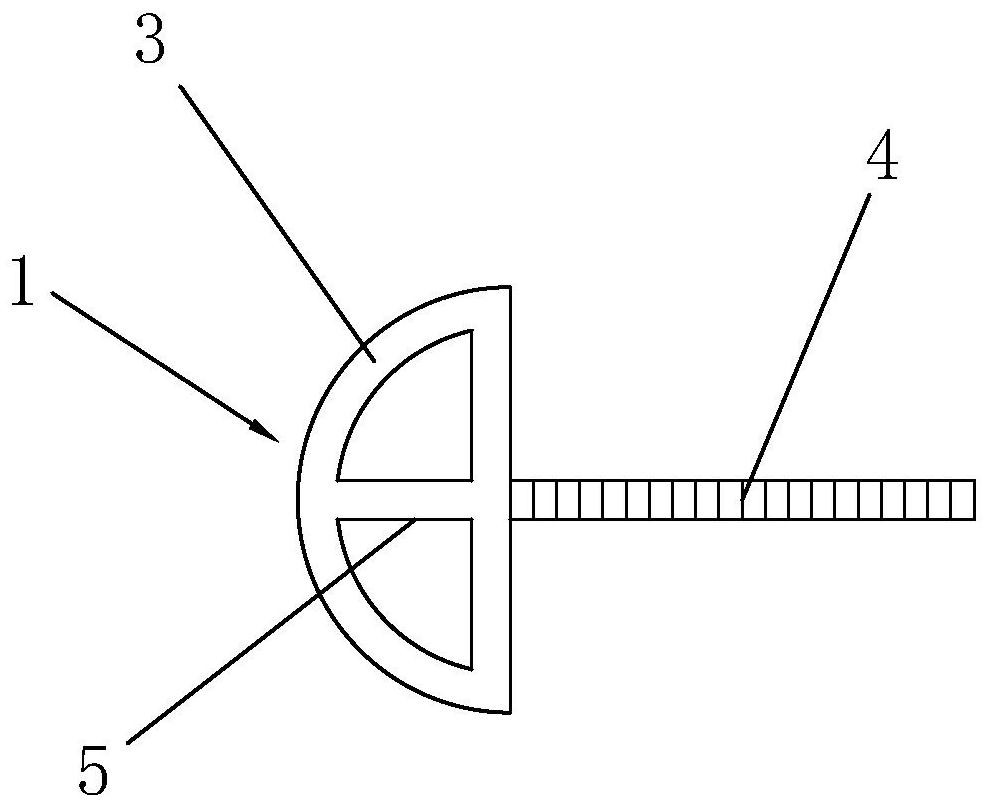

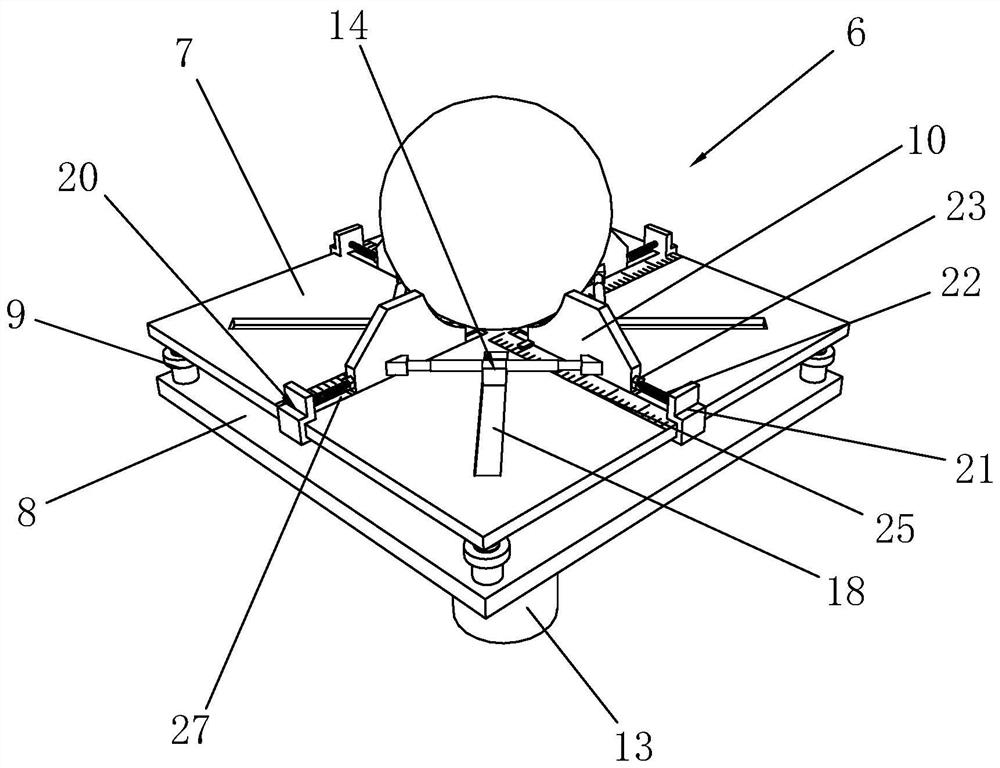

[0051] Such as Figure 1 to Figure 20 As shown, it is a method for installing a curved steel reticulated shell structure with a gradual change in the starting span of the gable wall according to the present invention, which includes the following steps:

[0052] Step 1: Level the site, prepare the materials, perform the axis positioning before the installation of the gable structure, and install the concrete pre-embedded support on the concrete structure;

[0053] Step 2: Assemble the first batch of hoisting units, take a gable unit and a gable connecting side unit respectively, connect the two with the concrete pre-embedded support to form an angle, and erect a temporary fix on the inner ball joint at the bottom Device 6: The inner spherical joint is supported by the temporary fixing device 6, and the outer spherical joint is supported by the concrete pre-embedded support, so that the inner and outer spherical joints are jointly supported by the mutual cooperation of the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com