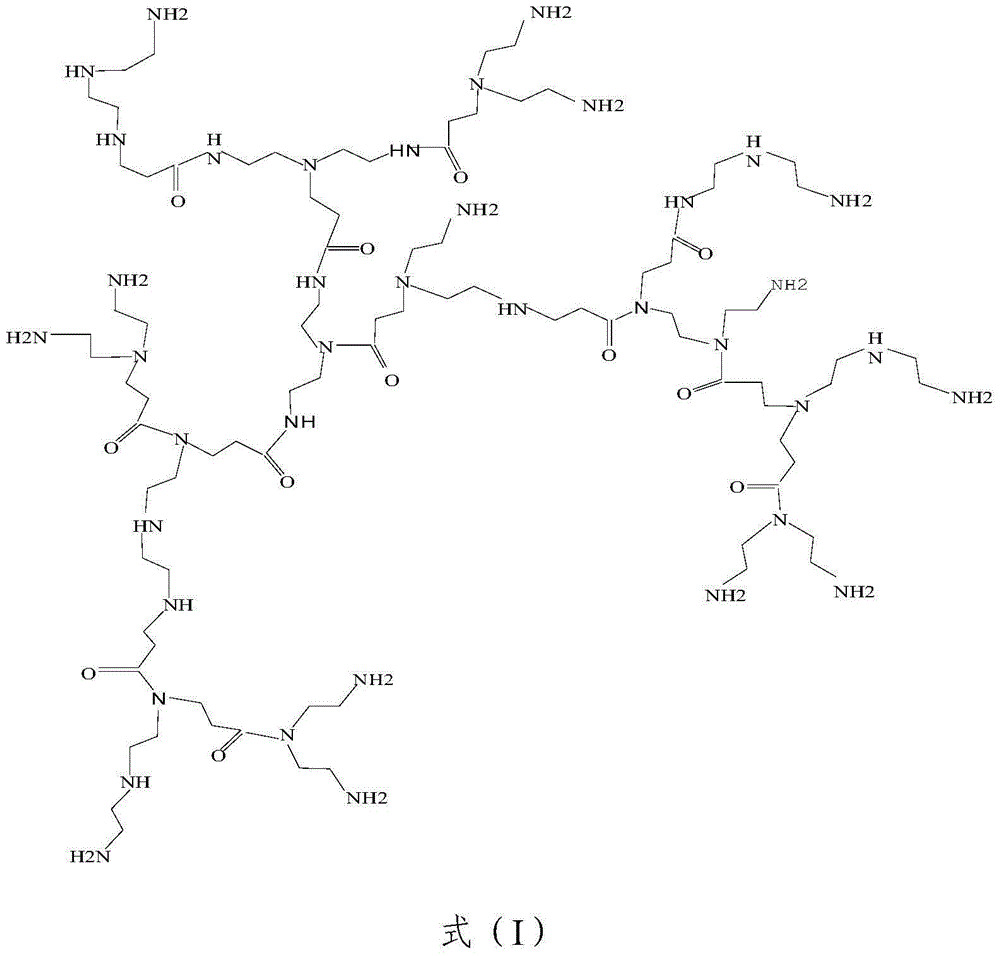

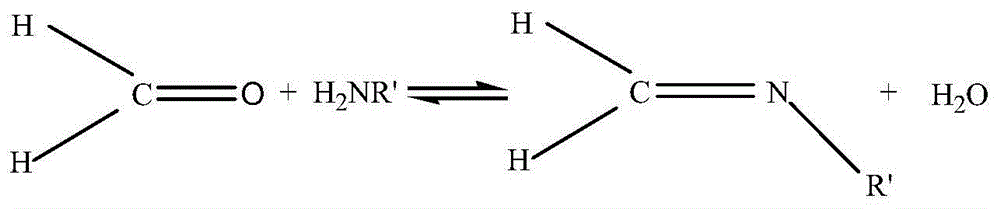

Formaldehyde catching agent and preparation method thereof

A technology of formaldehyde scavenger and auxiliary agent, applied in the field of formaldehyde scavenger and its preparation, can solve the problems such as short effective time of formaldehyde remover, inability to remove formaldehyde well, limited effective ingredients, etc., achieves good market application prospects, easy to use Get, long-lasting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 formaldehyde capture agent and preparation thereof

[0030] Add methyl acrylate monomer to the methanol solution of divinyltriamine (the content of divinyltriamine is 35%), the molar ratio of divinyltriamine to methyl acrylate is 1:1, and the reaction temperature is controlled at 0°C , control the reaction time to 8 hours, add 5% by weight of initiator A, gradually increase the temperature, the temperature is divided into four stages, respectively 60 ℃, 100 ℃, 120 ℃ and 140 ℃, and the initial stage (heating to 60 ℃, 100°C) to maintain the vacuum with a water pump, and use an oil pump after the third stage (heating to 120°C, 140°C). The total reaction time is 8 hours, add 100% deionized water by weight, stir well, add 5% of auxiliary agent B, 5% of auxiliary agent C (succinic acid disulfide), and mix and stir at 50°C to obtain Efficient polymer formaldehyde capture agent.

Embodiment 2

[0031] Embodiment 2 formaldehyde capture agent and preparation thereof

[0032] Add methyl acrylate monomer to the methanol solution of divinyltriamine (the content of divinyltriamine is 35%), the molar ratio of divinyltriamine to methyl acrylate is 1:1.2, and the reaction temperature is controlled at 20°C , control the reaction time to 16 hours, add 5% by weight of initiator A, and gradually increase the temperature. The temperature rise is divided into four stages, namely 60°C, 100°C, 120°C and 140°C. The initial stage (heating to 60°C, 100°C) to maintain the vacuum with a water pump, and use an oil pump after the third stage (heating to 120°C, 140°C). The total reaction time is 16 hours, add 200% by weight of deionized water, stir well, add 5% of auxiliary agent B, 5% of auxiliary agent C (adipic disulfide), and mix and stir at 50°C to obtain Efficient polymer formaldehyde capture agent.

Embodiment 3

[0033] Embodiment 3 formaldehyde capture agent and preparation thereof

[0034] Add methyl acrylate monomer to the methanol solution of divinyltriamine (the content of divinyltriamine is 35%), the molar ratio of divinyltriamine to methyl acrylate is 1:1.5, and the reaction temperature is controlled at 20°C , control the reaction time to 24 hours, add 5% by weight of initiator A, and gradually increase the temperature. The temperature rise is divided into four stages, namely 60°C, 100°C, 120°C and 140°C. The initial stage (heating to 60°C, 100°C) to maintain the vacuum with a water pump, and use an oil pump after the third stage (heating to 120°C, 140°C). The total reaction time is 24 hours, add 400% by weight of deionized water, stir well, add 5% of auxiliary agent B, 5% of auxiliary agent C (sebacic acid diacid) and mix and stir at 50°C to obtain Efficient polymer formaldehyde capture agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com