Anti-static release film and manufacturing method thereof

An antistatic, release film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of dust adsorption, affecting processing quality, damage to electronic components, etc., to achieve easy implementation, Simple and easy preparation method

Inactive Publication Date: 2010-11-17

李刚

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the base material of ordinary release film is polyester material, which is an insulator, it is easy to generate static electricity in the process of winding and unwinding. Light static electricity will cause dust to be absorbed and affect the quality of post-processing. Heavy static electricity will cause contact with it. Electronic components are damaged by high voltage discharge

In the traditional coating process of release film, antistatic coatings and release coatings are incompatible. At present, there are only pure antistatic films or simple release films on the market, and none have both antistatic function and release film. Functional release film

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

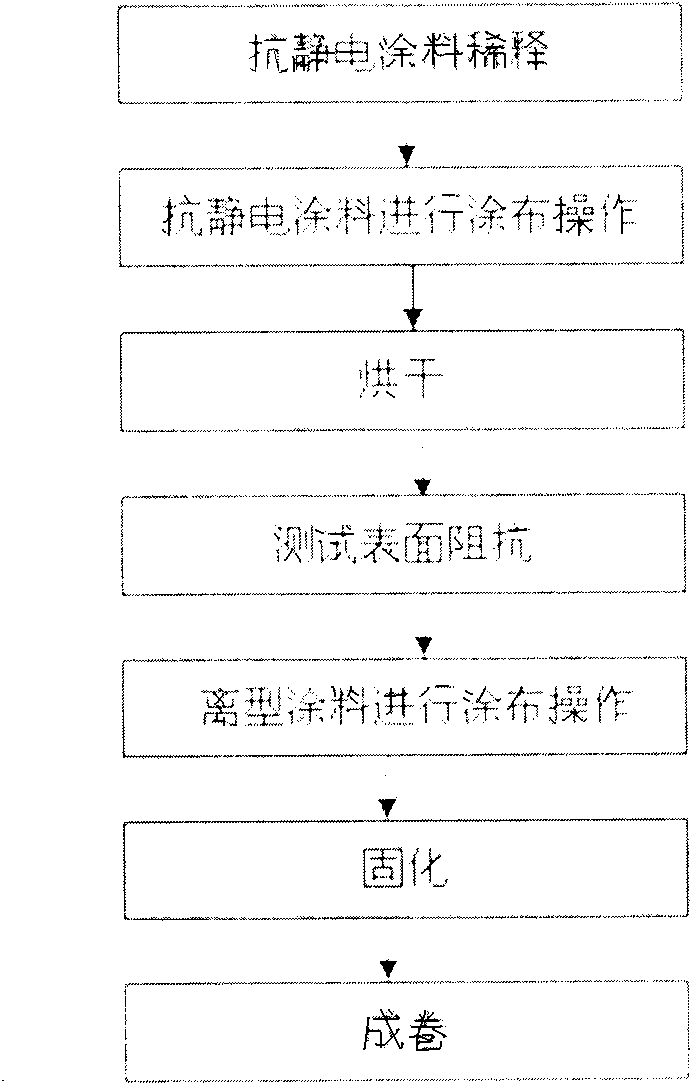

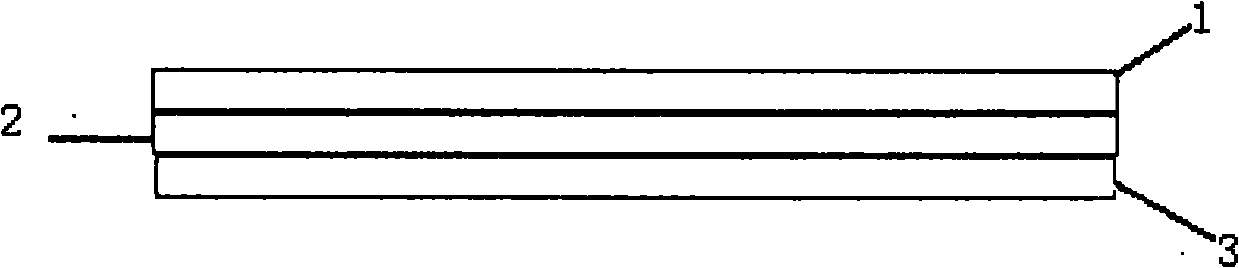

The invention discloses an anti-static release film and a manufacturing method thereof. The anti-static release film comprises three layers, wherein the first layer is a base material of which the main component is polyethylene glycol terephthalate (PET); the second layer is a conductive coating of which the main component is a conductive macromolecular compound with a polythiophene and polyaniline-containing co-orbit macromolecular structure; and the third layer is a release agent coating of which the main component is an addition organic silicon material. The manufacturing method comprises the following steps of: firstly, diluting and coating an anti-static coating; secondly, drying the coating; thirdly, testing surface impedance, and finally, coating a release coating and solidifying the coating to form a roll. The anti-static release film has the advantages of high release force and conductivity, and release and anti-static effects.

Description

technical field The invention relates to a release film, in particular to an antistatic release film used in die-cutting, shielding and protection industries of the electronic industry and a manufacturing method thereof. Background technique With the development of LCD, LED, PC, mobile phone and other industries, the demand for release film is increasing day by day, and the requirements are getting higher and higher. One of them is that the release film has antistatic function. Since the base material of ordinary release film is polyester material, which is an insulator, it is easy to generate static electricity in the process of winding and unwinding. Light static electricity will cause dust to be absorbed and affect the quality of post-processing. Heavy static electricity will cause contact with it. Electronic components are damaged by high voltage discharge. In the traditional coating process of release film, antistatic coatings and release coatings are incompatible. At...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B27/06B32B27/08B32B27/28B32B27/36

Inventor 李刚

Owner 李刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com