Preparation method of antistatic hard polyvinyl chloride material

A rigid polyvinyl chloride, antistatic technology, applied in the field of functional material preparation, can solve the problems of PVC material mechanical properties decline, high cost, compatibility between graphene and PVC, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Microwave-exfoliated expandable graphite, carbon fiber, and PVC composites were prepared by blending molding.

[0020] Preparation process steps:

[0021] (1) Using expandable graphite with a particle size of 200 mesh and a carbon content greater than 99.5w% as a raw material, place the expandable graphite in a microwave heating chamber, and under the condition of a microwave power of 3KW, at a temperature of 50°C / min The heating rate is such that the temperature in the microwave heating chamber is raised from normal temperature to 400-600° C., and the treatment time is 1 minute to obtain microwave-exfoliated expanded graphite.

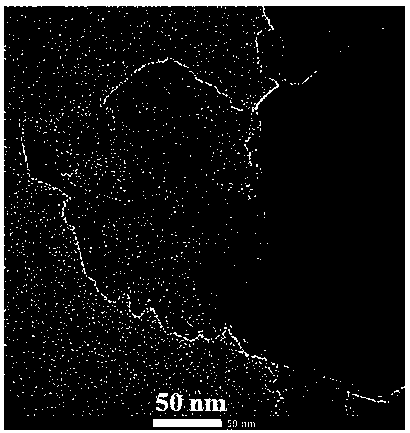

[0022] Depend on figure 1 It can be seen that the expandable graphite is exfoliated by microwave, and the expanded graphite is a mixture of nano-graphite flakes and graphite flakes.

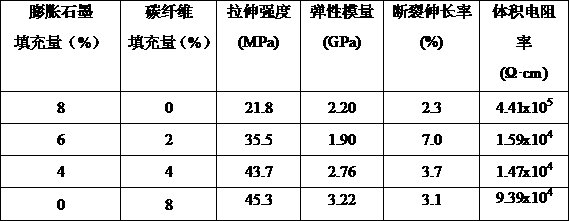

[0023] (2) X g microwave exfoliated expanded graphite and Y g carbon fiber (wherein X and Y coordinates are: 8 and 0; 6 and 2; 4 and 4; 0 and 8), respectively, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com