Cleaning and polishing integrated antistatic automobile polishing wax and preparation method thereof

An antistatic and polishing wax technology, applied in chemical instruments and methods, polishing compositions, detergent compounding agents, etc., can solve problems such as poor use effect, tarnishing, corrosion, etc., and achieve strong cleaning and dust removal ability, antistatic The effect is remarkable and the production cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

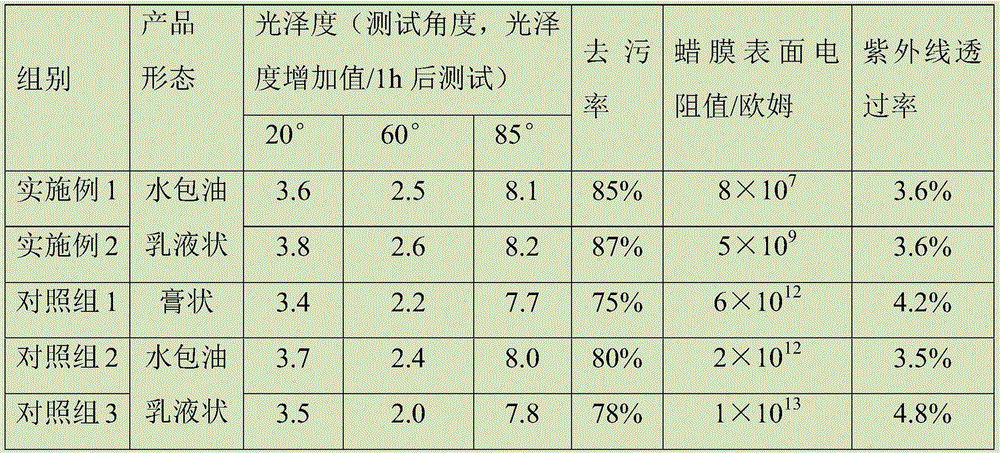

Examples

Embodiment 1

[0031] An antistatic car polishing wax integrating cleaning and glazing, its components are, by mass fraction, 1% of antistatic agent, 7% of emulsion, 25% of compound solution, and 1.5% of polydimethylsiloxane , UV absorber 0.3%, preservative 0.2% and deionized water 65%.

[0032] Among them, the antistatic agent is sulfonated styrene and maleic acid polymer, namely TL-3 (AkzoNobel, USA).

[0033] Among them, the solute of the emulsion is a mixture of carnauba wax (Suzhou Bernuo Rubber and Plastic Materials Co., Ltd.), paraffin wax (Maoming Petrochemical Nanhai brand), Fischer-Tropsch wax (Malaysia Shell) and emulsifier (Zibo Huitong Oil Fine Chemical Co., Ltd.) , the solvent is an emulsifier, the mass fraction of the solute is 15%, and the mass ratio of carnauba wax, paraffin wax and Fischer-Tropsch wax in the solute is 2:4:1.

[0034] Wherein, the compound solution is a cationic and non-ionic surfactant, and the component of the compound solution is dodecyltrimethylammoni...

Embodiment 2

[0047] An antistatic car polishing wax integrating cleaning and glazing, its components are, by mass fraction, 3% of antistatic agent, 5% of emulsion, 35% of compound solution, and 1.5% of polydimethylsiloxane , UV absorber 0.3%, preservative 0.2% and deionized water 55%.

[0048] Among them, the antistatic agent is sulfonated polystyrene polymer, namely TL-130 (AkzoNobel, USA).

[0049] Among them, the solute of the emulsion is a mixture of carnauba wax (Suzhou Bernuo Rubber and Plastic Materials Co., Ltd.), paraffin wax (Maoming Petrochemical Nanhai brand), Fischer-Tropsch wax (Malaysia Shell) and emulsifier (Zibo Huitong Oil Fine Chemical Co., Ltd.) , the solvent is an emulsifier, the mass fraction of the solute is 15%, and the mass ratio of carnauba wax, paraffin wax, and Fischer-Tropsch wax in the solute is 2:8:1.

[0050] Wherein, the compound solution is a cationic and non-ionic surfactant, and the component of the compound solution is dodecyltrimethylammonium chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com