A kind of superhydrophobic composite material additive and preparation method thereof

A composite material and additive technology, used in organic chemistry, coatings, etc., can solve the problems of poor weather resistance of super-hydrophobic materials, covering with hydrophobic properties, easy to deposit dust, etc., and achieve the effect of improving hydrophobicity and adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of superhydrophobic composite additives:

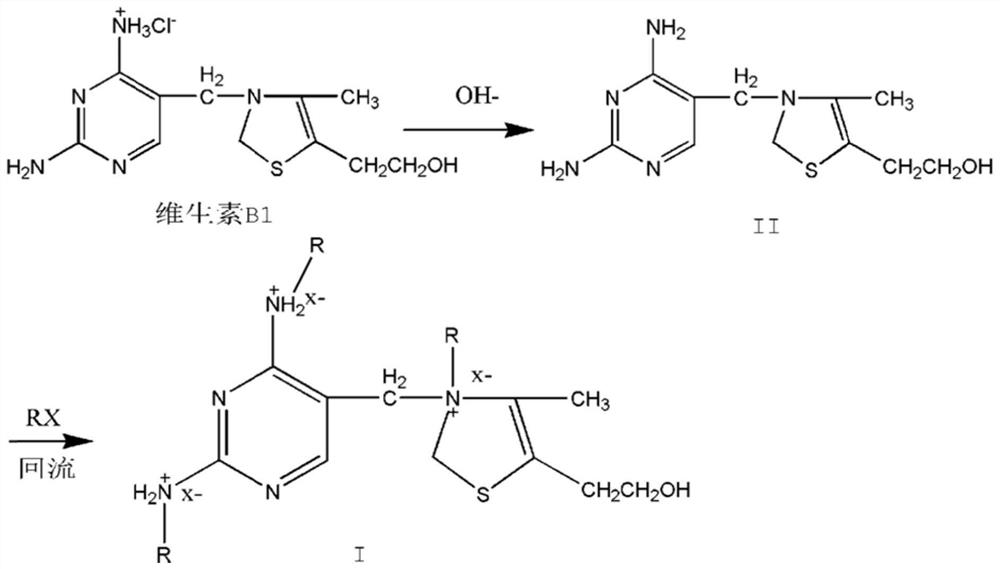

[0036] (1) 0.1mol vitamin B1 is added into 58ml molar concentration and is 2mol / L sodium hydroxide aqueous solution, stirs, and now sodium hydroxide and the ammonium ion on the vitamin B1 pyrimidine ring neutralize reaction, obtain product (II), And precipitated in water, the precipitate was filtered, washed and dried to obtain 0.08mol product (II);

[0037] (2) Add 0.05mol of the product (II) obtained in step (1) into DMSO, and simultaneously add 0.16mol

[0038] The ethyl bromide was stirred and heated to reflux for 24h. At this time, the product (II) and ethyl bromide had an affinity substitution reaction to obtain the superhydrophobic composite material additive (I), and precipitated in DMSO, and the obtained superhydrophobic composite material additive (1) precipitation filtration separation, obtains 0.045mol superhydrophobic composite material additive (I), as figure 1 Shown is a schematic diagram of the syn...

Embodiment 2

[0041] Preparation of superhydrophobic composite additives:

[0042] (1) 0.1mol vitamin B1 is added into 50ml molar concentration and is 2mol / L sodium hydroxide aqueous solution, stirs, and now sodium hydroxide and the ammonium ion on the vitamin B1 pyrimidine ring undergo a neutralization reaction to obtain product (II), And precipitated in water, the precipitate was filtered, washed and dried to obtain 0.08mol product (II);

[0043] (2) Add the product (II) that 0.05mol step (1) obtains in DMSO, add 0.15mol bromoethane simultaneously and stir, heat and reflux 24h, this moment product (II) and bromoethane generation affinity substitution reaction, Obtain superhydrophobic composite material additive (I), and precipitate in DMSO, the superhydrophobic composite material additive (I) precipitation filtration separation that obtains, obtain 0.045mol superhydrophobic composite material additive (I), as figure 1 Shown is a schematic diagram of the synthesis process of the superhydr...

Embodiment 3

[0045] Preparation of superhydrophobic composite additives:

[0046] (1) Add 0.1mol vitamin B1 to 60ml molar concentration and be 2mol / L sodium hydroxide aqueous solution, stir, and now sodium hydroxide and the ammonium ion on the vitamin B1 pyrimidine ring undergo a neutralization reaction to obtain product (II), And precipitated in water, the precipitate was filtered, washed and dried to obtain 0.08mol product (II);

[0047] (2) Add the product (II) that 0.05mol step (1) obtains in DMSO, add 0.165mol bromoethane simultaneously and stir, heat and reflux 24h, this moment product (II) and bromoethane generation affinity substitution reaction, Obtain superhydrophobic composite material additive (I), and precipitate in DMSO, the superhydrophobic composite material additive (I) precipitation filtration separation that obtains, obtain 0.045mol superhydrophobic composite material additive (I), as figure 1 Shown is a schematic diagram of the synthesis process of the superhydrophobic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com