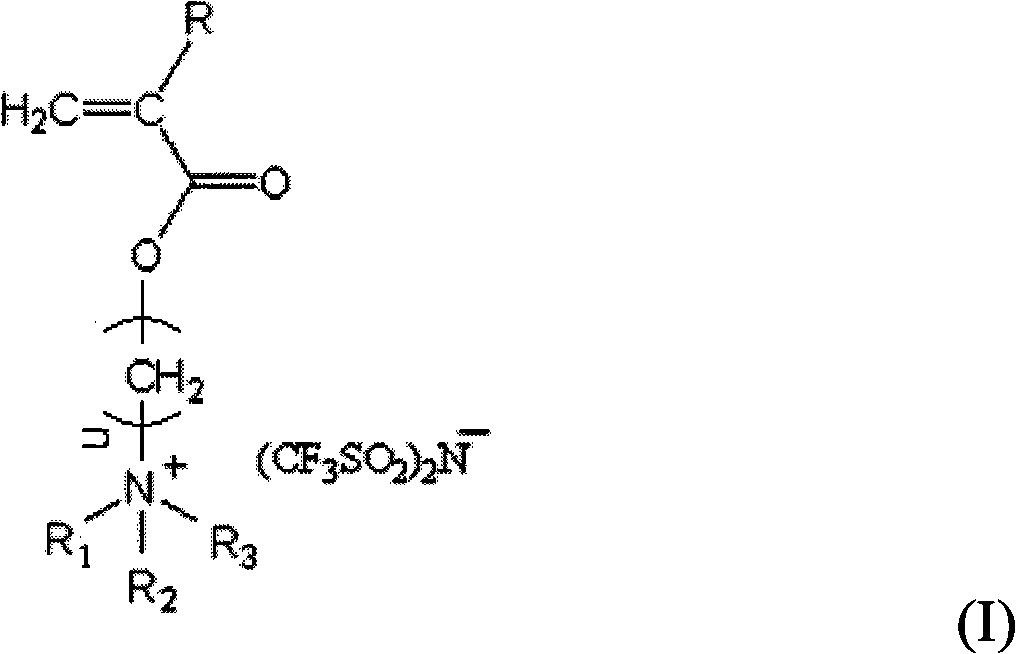

Antistatic ionic compound, oligomer thereof, copolymer thereof and pressure-sensing agglutinant component thereof

A technology of ionic compounds and compositions, applied in the direction of non-polymer organic compound adhesives, ester copolymer adhesives, adhesives, etc., can solve the problem of reducing the performance of pressure-sensitive adhesives, poor transparency, and affecting pressure-sensitive adhesion The optical properties of the agent and other problems can be solved to achieve the effect of no deterioration of adhesion and excellent antistatic property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0056] The preparation of preparation example methacrylate polymer (A)

[0057] Put 189.4 parts by weight of butyl acrylate, 10 parts by weight of acrylic acid, and 0.6 parts by weight of hydroxyethyl methacrylate into a four-necked flask equipped with stirring blades, a thermometer, a nitrogen gas inlet tube, and a condenser as a polymerization initiator 0.16 parts by weight of 2,2'-azobisisobutyronitrile, and 466 parts by weight of ethyl acetate as a solvent, after nitrogen gas was introduced for about 30 minutes under gentle stirring, the polymerization reaction was carried out for about 8 hours, and the flask The temperature of the liquid inside was maintained at about 60° C., and after cooling to room temperature, 334 parts by weight of ethyl acetate was added for dilution, thus preparing a polymer (A) mainly composed of acrylate (solid content: 20%). The glass transition temperature of the polymer (A) was -44° C. and the weight average molecular weight was 1,280,000 as m...

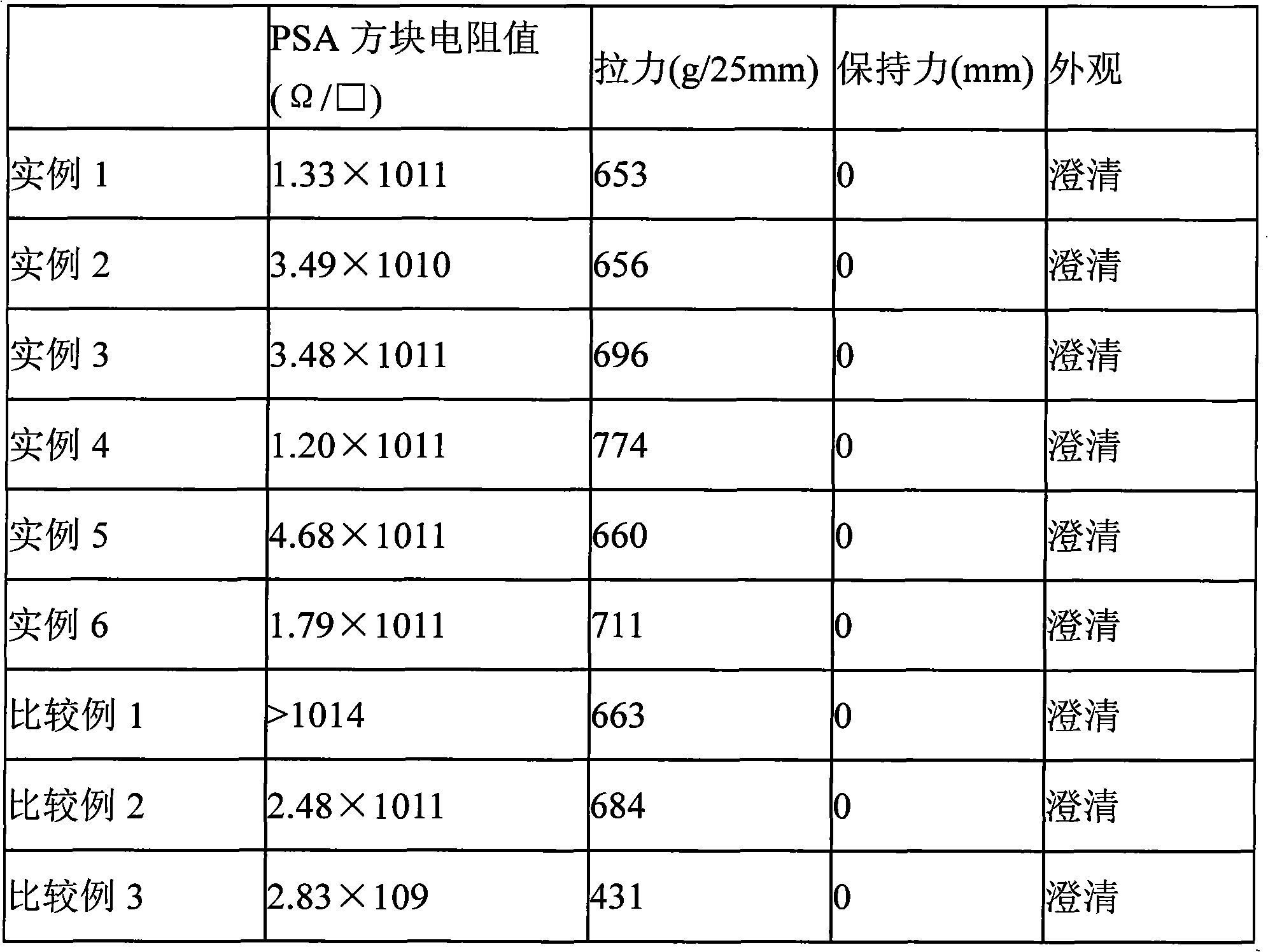

example 1

[0066] Preparation of pressure-sensitive adhesive composition according to the present invention

[0067] Add 0.1 weight part of the above-mentioned synthetic example 1 in the solution of the polymer (A) based on propylene group obtained in the above-mentioned preparation example of 100 parts by weight (the polymer (A) based on propylene group accounts for 20 weight percent) Gained ionic compound (a), also add following medicine in addition as cross-linking agent and additive: 0.4 parts by weight of polyisocyanate (polyisocyanate) adduct (toluene diisocyanate-trihydroxymethyl propaneadduct, Japan Polyurethane Industry Co., Ltd. (abbreviated as NPU company) manufacture) , 0.8 parts by weight of aluminum acetylacetonate (aluminum acetylacetonate), and 0.04 parts by weight of 3-glycidyl etheroxypropyl trimethoxysilane (glycidoxypropyltrimethoxysilane, product code Z-6040, manufactured by U.S. Dow Corning (Dow Corning) Co., Ltd.) , mixed and stirred at room temperature for about 5...

example 2

[0071] Preparation of pressure-sensitive adhesive composition according to the present invention

[0072] The preparation steps of the acrylic pressure-sensitive adhesive solution are the same as in Example 1, but 1 part by weight of the ionic compound (a) is added instead of 0.1 part by weight.

[0073] Preparation of pressure-sensitive adhesive sheets

[0074] Same as example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com