High-strength steel wire net framework polyethylene pipe

A high-strength steel wire and polyethylene pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as burrs, inability to use ventilation or water supply and drainage, and affect the normal flow of media in the pipe, etc., to achieve manufacturing costs Low, high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

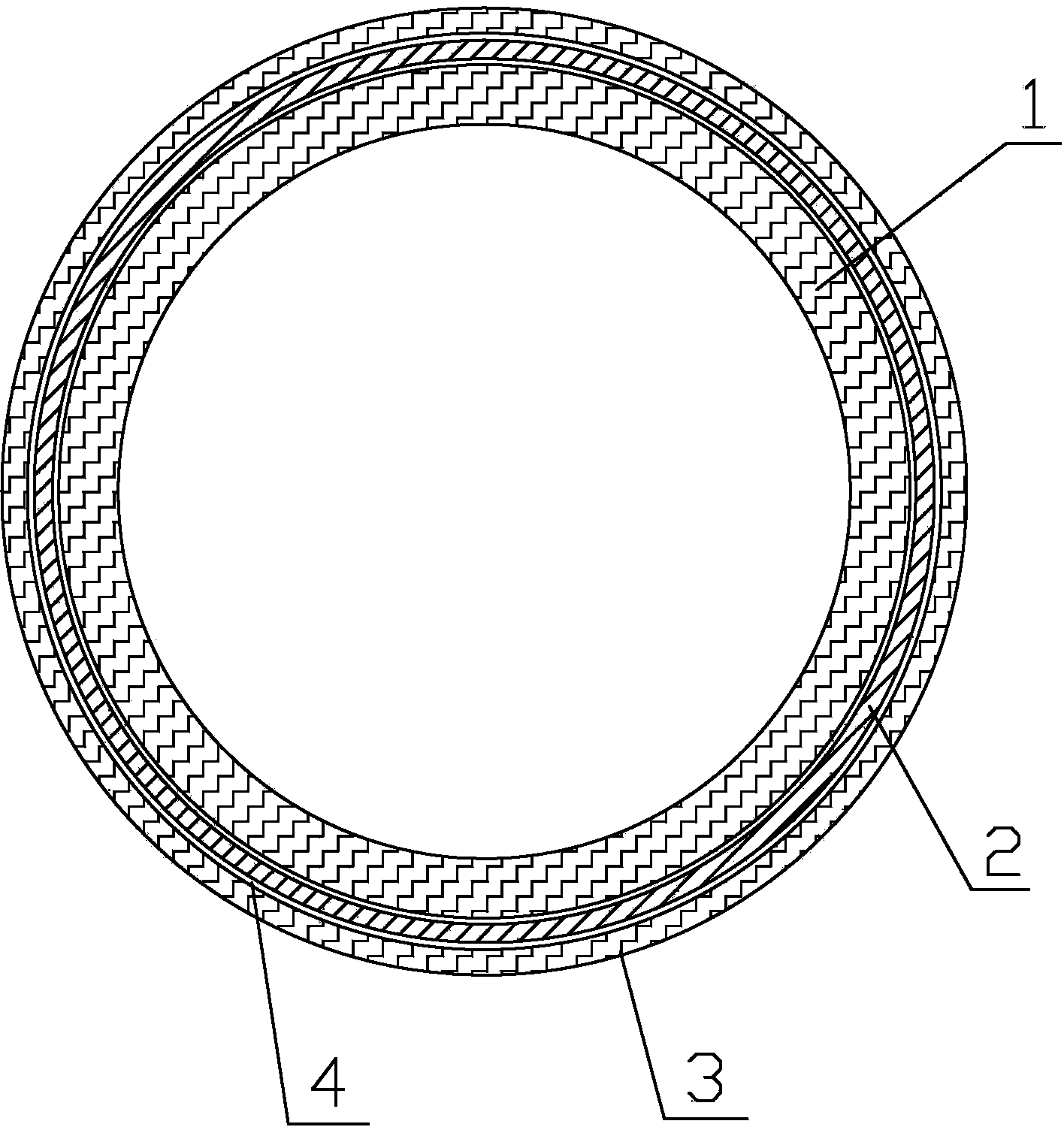

[0013] Such as figure 1 As shown, the high-strength steel mesh skeleton polyethylene pipe includes an inner layer 1, a reinforcement layer 2 and an outer surface protection layer 3. The inner layer 1 is made of flame-retardant and antistatic polyethylene material, and the reinforcement layer 2 is made of steel mesh layer. Composed of a hot melt adhesive layer, the protective layer 3 is made of flame retardant and antistatic polyethylene material, and a hot melt adhesive layer 4 is respectively arranged between the steel mesh layer, the inner layer and the protective layer.

[0014] In this embodiment, the steel mesh layer is composed of one or two layers of steel mesh, and a hot melt adhesive layer 4 is arranged between the two layers of steel mesh, and the mesh of the outer layer of steel mesh is larger than that of the inner layer of steel mesh. hole, the hot melt adhesive is polyethylene hot melt adhesive. The steel wires constituting the steel mesh are spring steel wires,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com