Light-emitting device and illuminating device

A technology for light-emitting devices and light-emitting elements, which is applied to electrical components, electric solid-state devices, circuits, etc., can solve the problems of not being able to improve the luminous efficiency of phosphors, and the luminous efficiency of light-emitting devices, so as to reduce uneven hues and suppress luminescence. Efficiency drop and joint strength enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

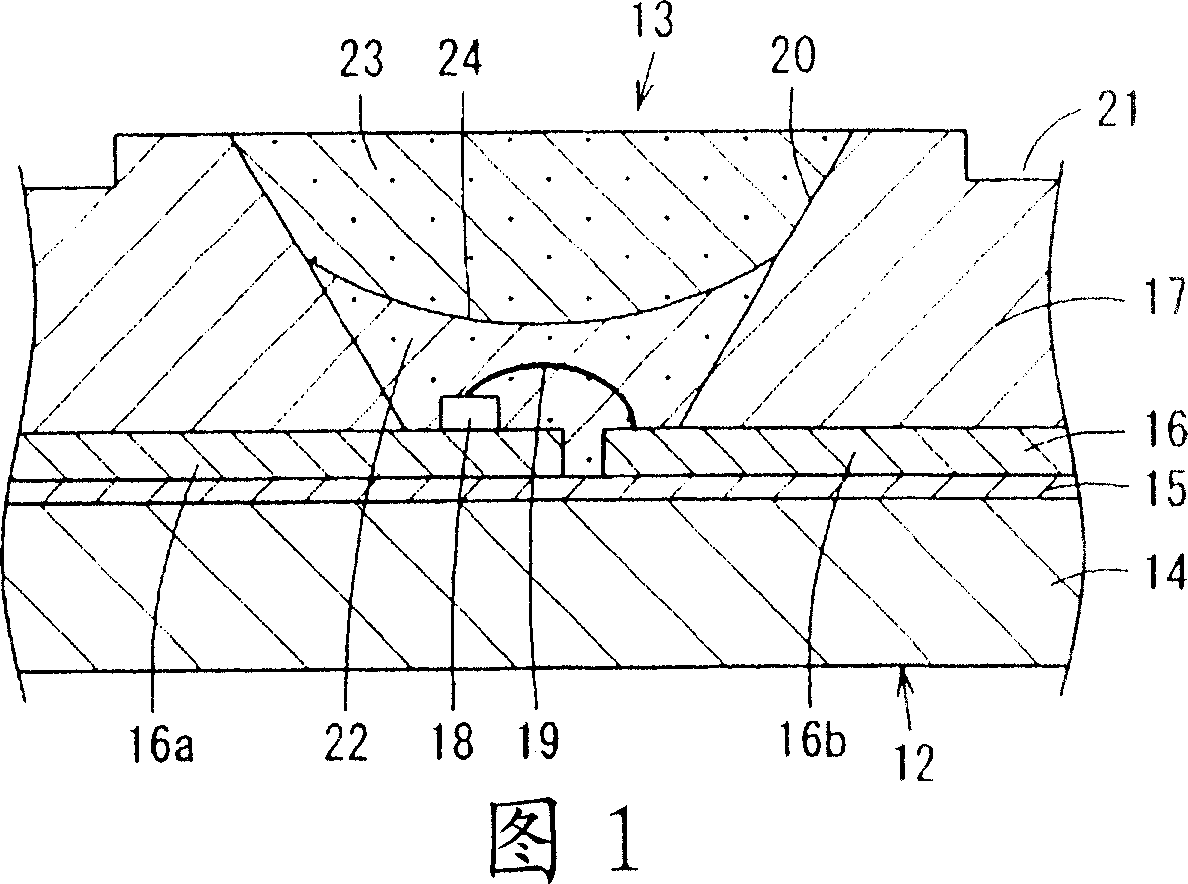

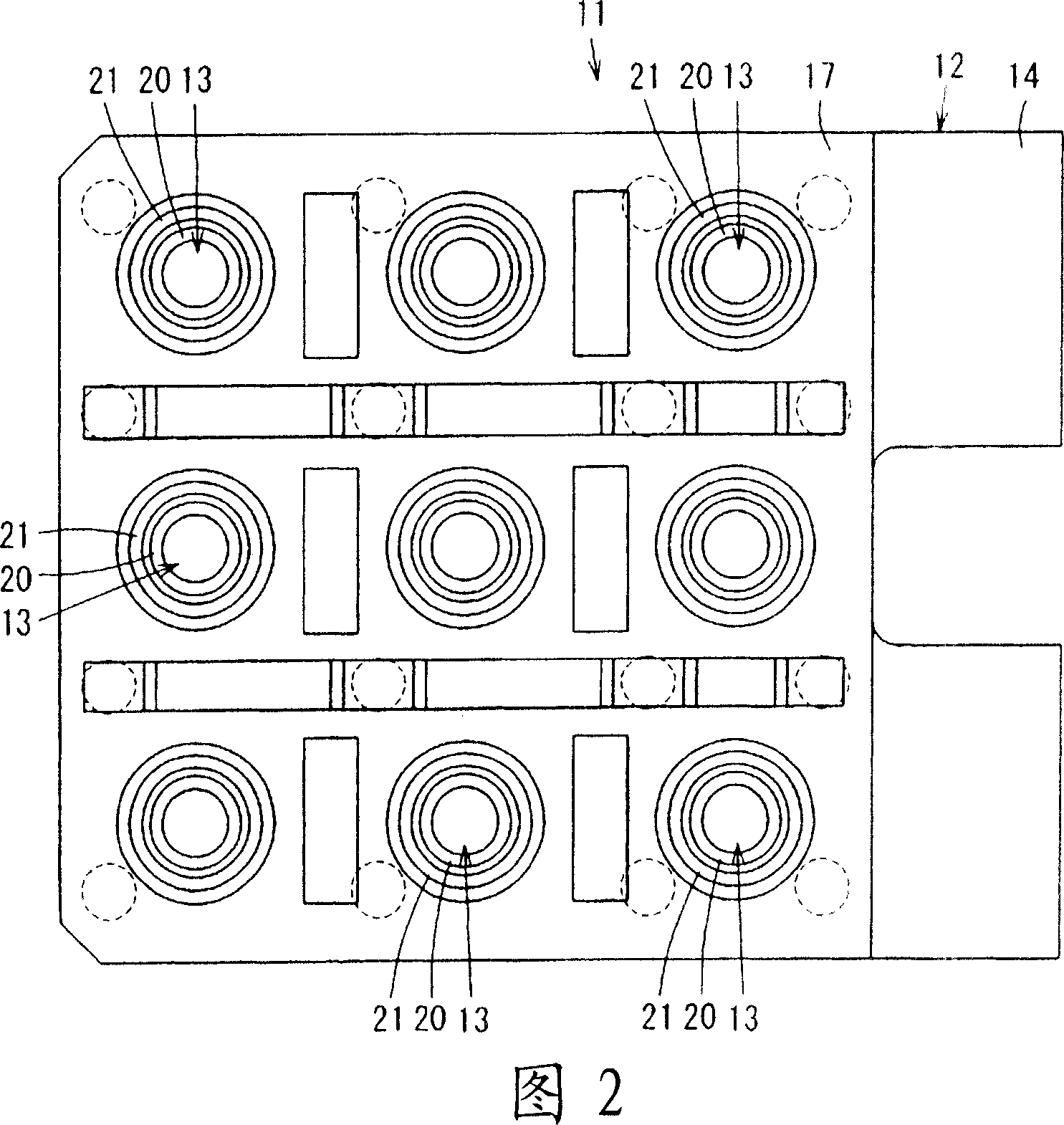

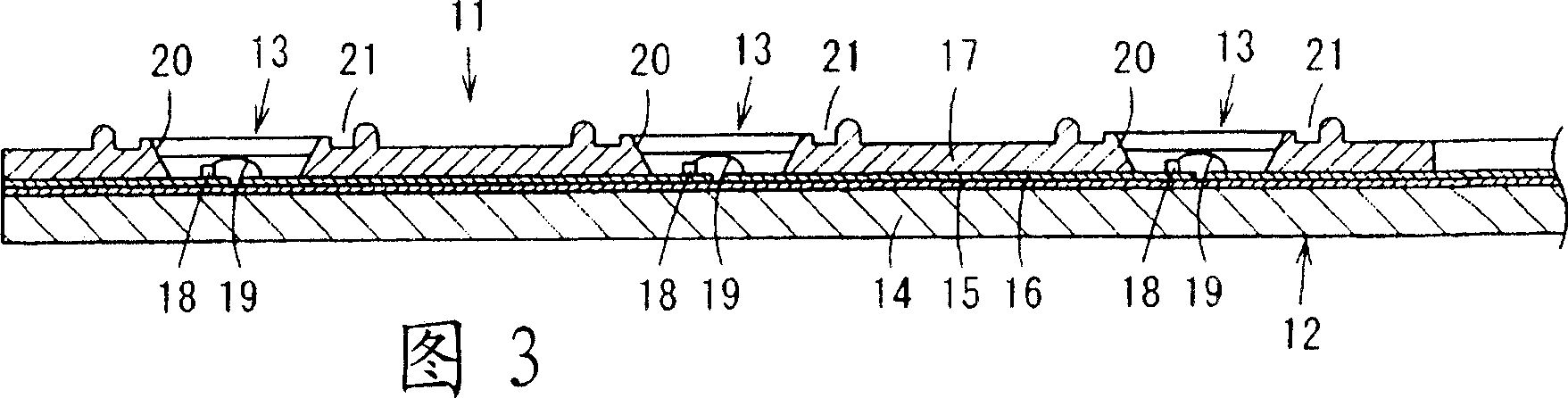

[0064] 1 to 4 show a first embodiment of the present invention. 1 is a partial enlarged cross-sectional view of a light emitting device, FIG. 2 is a top view of the light emitting device, FIG. 3 is a cross-sectional view of the light emitting device, and FIG. 4 is a table showing the relationship between the amount of scattering agent added and the light beam of the light emitting device.

[0065] As shown in FIGS. 2 and 3 , the light-emitting device 11 has a base material 12 on which a plurality of light-emitting element arrangement portions 13 are formed, for example, in a matrix of three rows and three columns.

[0066] The base material 12 has: a plate-shaped substrate 14 of aluminum (Al) or nickel (Ni), glass epoxy resin, etc. with heat dissipation and rigidity; an insulating layer 15 formed on the substrate 14; lead frame 16 ; and reflector 17 ′ formed on substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com