Friction welding method for copper and aluminum end faces

A technology of friction welding and end face, which is applied in the direction of welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low joint area, low joint strength, unstable friction coefficient, etc., to increase the joint area, improve the joint strength, Effect of reducing oxide impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

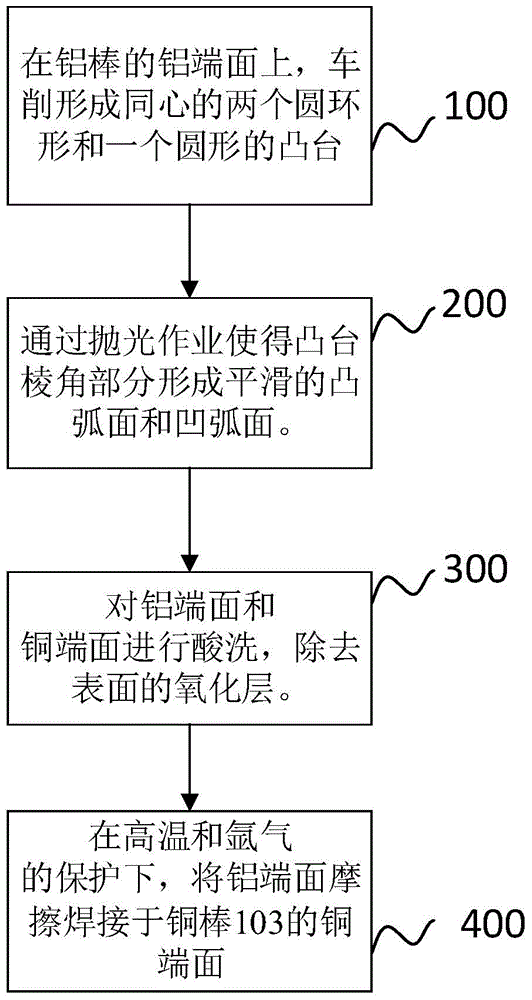

[0042] figure 1 It is the flow chart of the friction welding method of the copper-aluminum end face of embodiment 1 of the present invention, as figure 1 As shown, the friction welding method of the copper-aluminum end face involved in embodiment 1 includes the following steps:

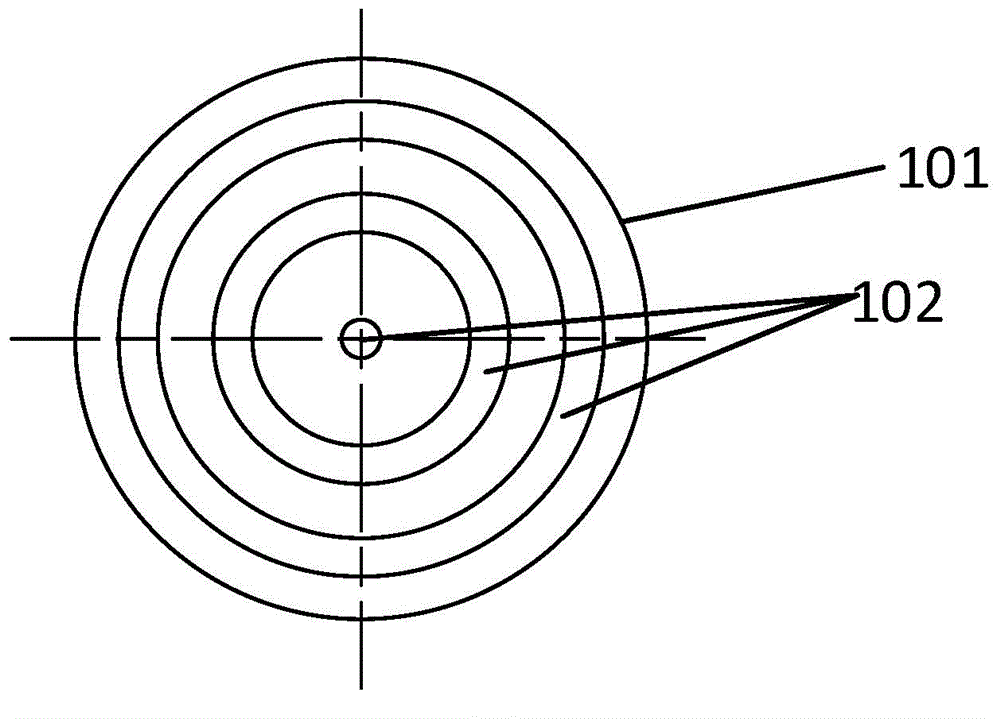

[0043] Step 100, on the aluminum end surface of the object to be welded (in this embodiment, an aluminum rod), machine tool turning process forms two concentric circular rings and a circular boss, and the section of the boss is the lower bottom and the aluminum end surface connected trapezoids. figure 2 It is the top view of the aluminum end face of embodiment 1, as figure 2 As shown, the aluminum end surface of the aluminum rod 101 is provided with a boss 102 .

[0044] Step 200 , using a polishing machine to polish the corners (including the angle between the waist and the bottom surface) of the boss until all the parts with corners form smooth arc surfaces.

[0045] Step 300, pickling the alu...

Embodiment 2

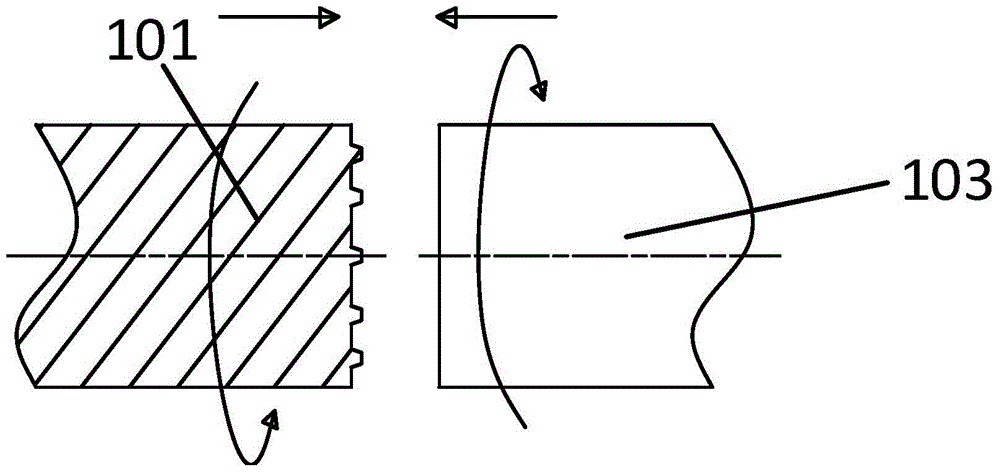

[0048] Figure 4 It is the flowchart of the friction welding method of the copper-aluminum end face of embodiment 2, figure 2 It is the top view of the aluminum end face of embodiment 2, image 3 It is the structural representation of the joint of the aluminum end face and the copper end face of embodiment 2, as Figure 2~4 As shown, the friction welding method of the copper-aluminum end face that embodiment 2 involves includes the following steps:

[0049] Step 1. On the aluminum end face of the object to be welded (in this embodiment, an aluminum rod), two concentric circular rings and a circular boss are formed by lathe turning. The cross section of the boss is the lower bottom and the aluminum end face. connected trapezoids. like figure 2 As shown, the aluminum end surface of the aluminum rod 101 is provided with a boss 102 .

[0050]Step 11, turning the copper end surface of the copper rod 103 to form a groove (not shown in the figure) that matches the shape of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com