Composite contact lens and production method for lens material

A technology for contact lenses and lens materials, applied in the directions of glasses/protective glasses, glasses/goggles, optics, etc., can solve problems such as lens breakage, and achieve the effects of preventing breakage, reducing breakage, and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

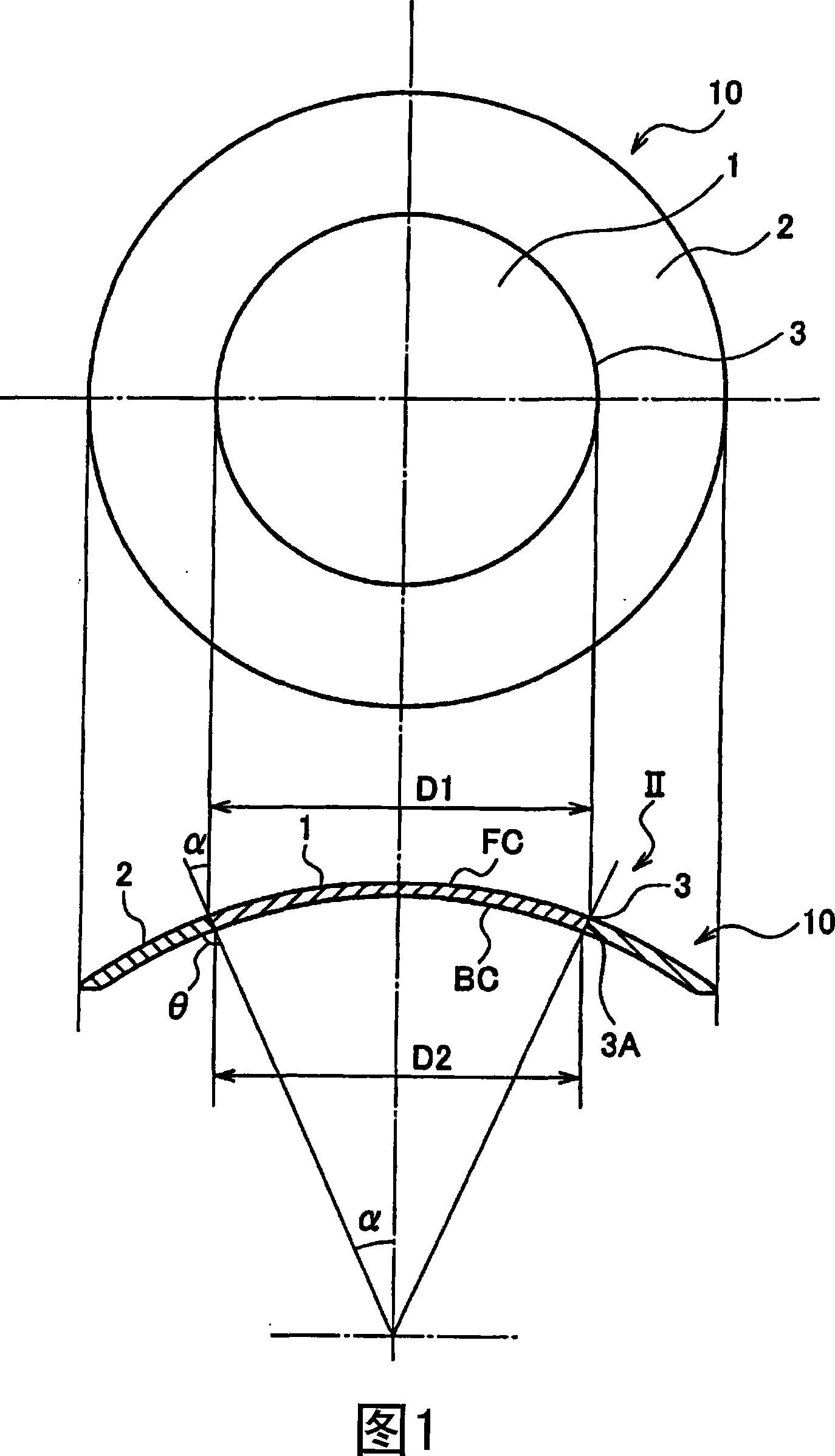

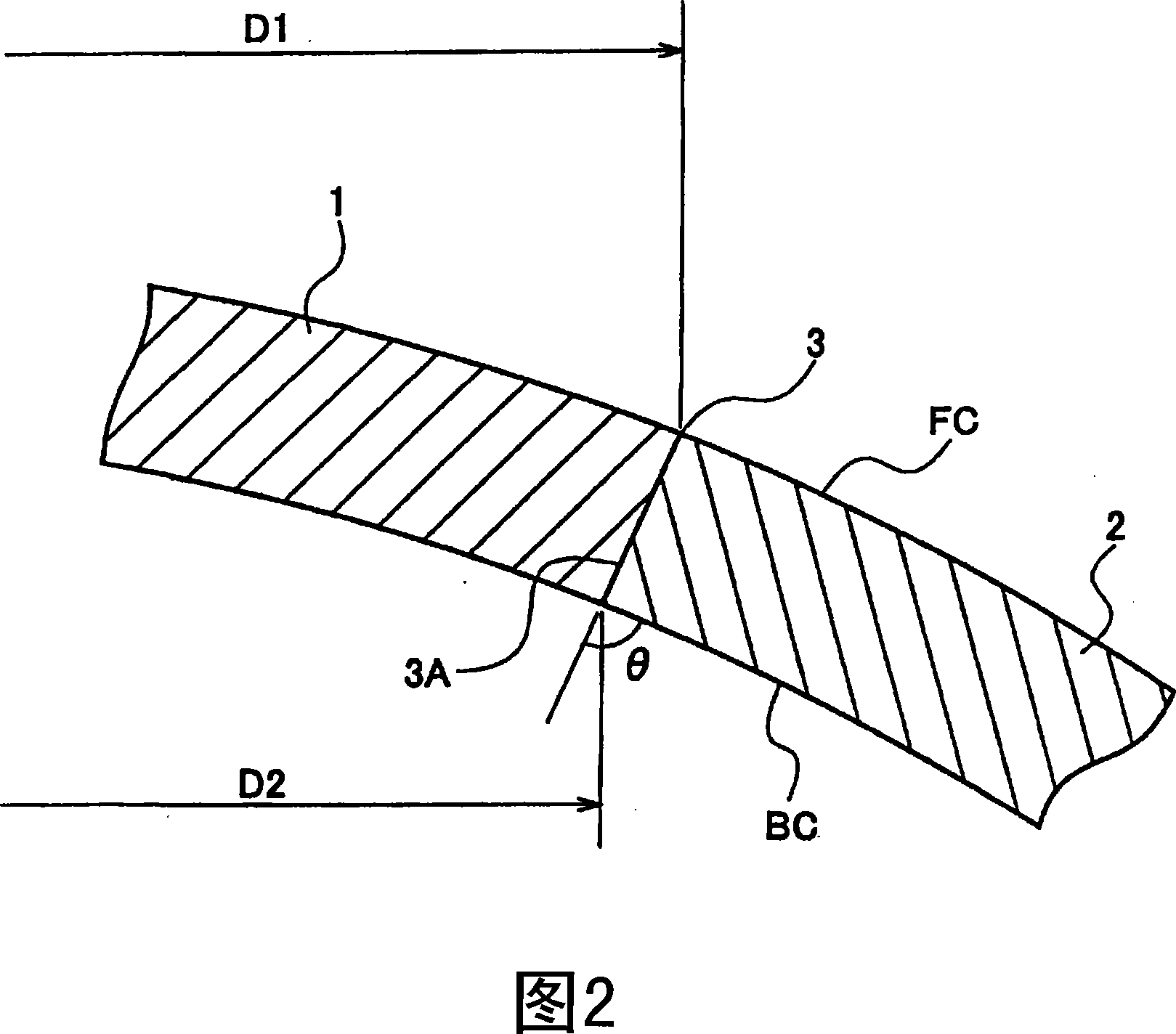

no. 1 example

[0120]First, in a mixture comprising 44% by weight of 2-hydroxyethyl methacrylate, 35% by weight of 2-methoxyethyl acrylate, 20% by weight of methyl methacrylate, and 1% by weight of ethylene glycol dimethyl 0.1% by weight of 2,2'-azobisisobutyrocyanide as a polymerization initiator was added to the monomer mixture of acrylate acrylate, and stirred to dissolve it.

[0121] Next, using [PA-100AT] produced by Kyoto Denshi Measurement Co., Ltd., the mixed solution was poured into the following polymerization vessel, which was cylindrical in shape, with an inner diameter of 17 mm, made of polypropylene, and output at 50 W , a vacuum degree of 0.6 Torr, a reaction gas of Ar, and a treatment time of 120 seconds for plasma treatment. After the polymerization container was sealed, it was placed in a hot air circulation dryer, kept at 40°C for 48 hours, kept at 80°C for 6 hours, and then naturally cooled to room temperature to obtain the peripheral polymer (soft material 32).

[0122...

no. 2 example

[0130] In Example 2, a composite contact lens was obtained in the same manner as in Example 1 except that the angle of inclination provided in the cavity of the peripheral material was changed to α=35°, and the evaluation was also the same as in Example 1.

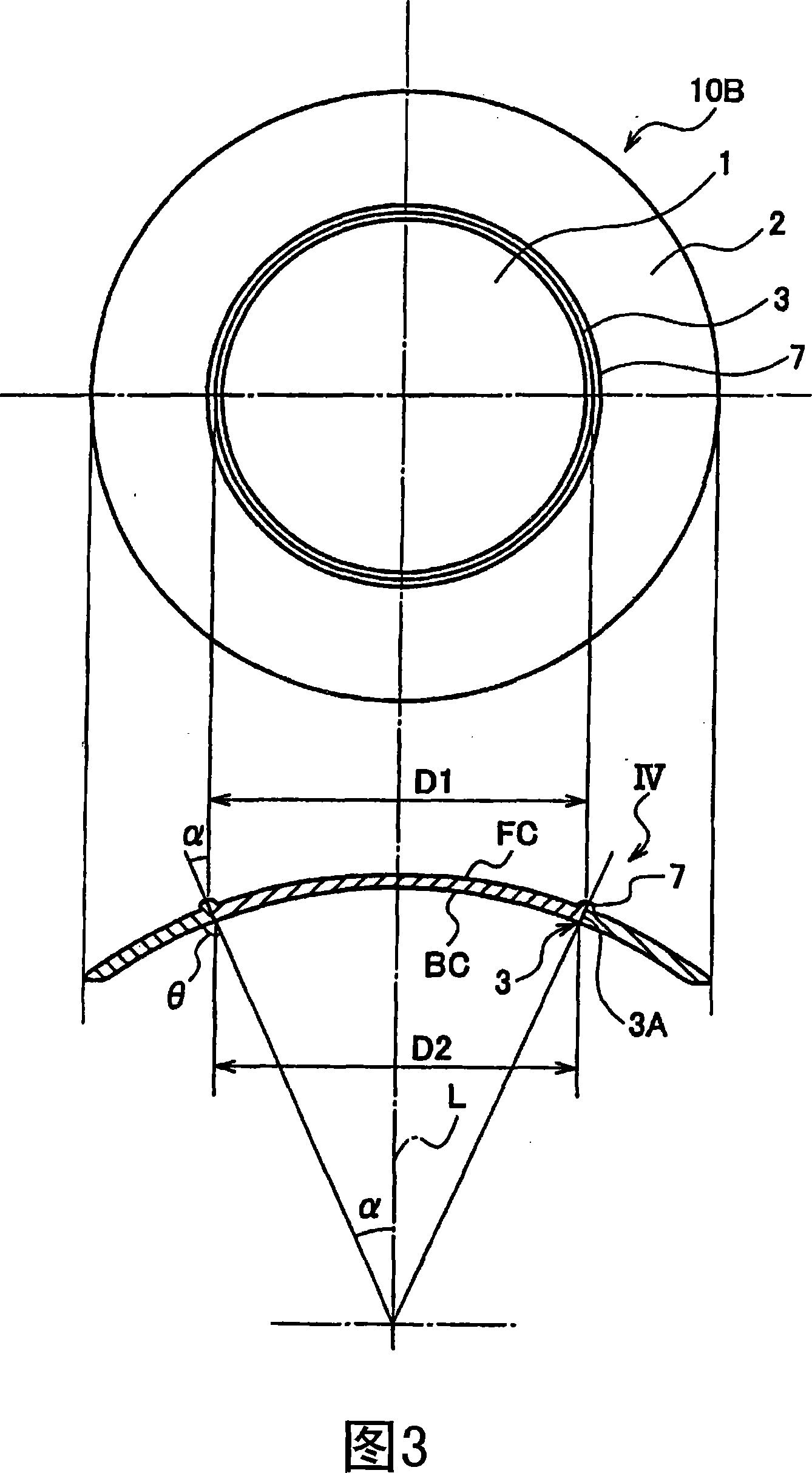

no. 3 example

[0132] Including 46% by weight of 2-hydroxyethyl methacrylate, 38% by weight of 2-methoxyethyl acrylate, 15% by weight of 2,2,2-trifluoroethyl methacrylate, and 1% by weight 0.1% by weight of 2,2'-azobisisobutyrocyanide as a polymerization initiator was added to the monomer mixture liquid of ethylene glycol dimethacrylate, and stirred to dissolve it.

[0133] Next, using [HV-2010] manufactured by TANTEC Corporation, the mixed liquid was poured into the following polymerization vessel, which was cylindrical in shape with an inner diameter of 17 mm, made of polypropylene, and spherical with a tip of 6 mm in the atmosphere. The electrodes were subjected to corona discharge treatment inside the polymerization container under the conditions of a set voltage of 24 kV, a set output of 51 W, and a treatment time of 5 seconds. After the polymerization container was sealed, it was placed in a hot air circulation dryer, kept at 42°C for forty-two hours, at 80°C for six hours, and then na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com