Emulsion paraffin for producing waterproof fiberboard and preparation method thereof

A technology for emulsifying paraffin and fiberboard, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of inflammability and explosion, increase production cost, pollute the environment, etc., and achieve the effect of good stability and good waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

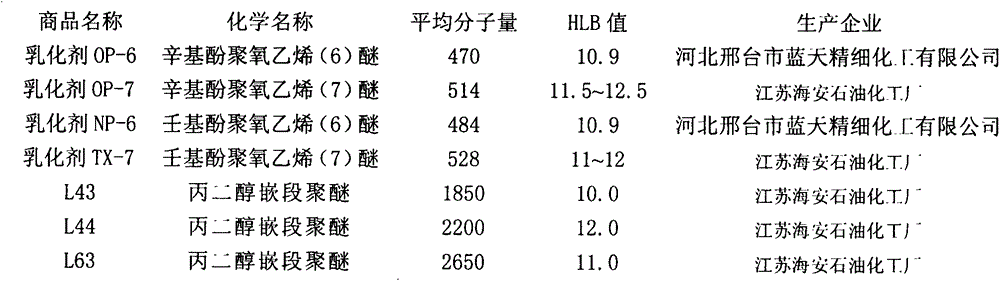

[0020] Add 30kg of solid paraffin, 1kg of emulsifier octylphenol polyoxyethylene (6) ether, 0.1kg of sodium perfluorooctanoate and 48.9kg of water into the emulsification tank, heat up to 90-95°C to melt the solid paraffin, and then add 20kg of pre-prepared 5% polyvinyl formal aqueous solution, the mixed system is spontaneously emulsified to form a milky white emulsion, and the emulsion is cooled to room temperature to obtain 100kg paraffin microemulsion. The average particle size of the product is 280±10nm, the stability is good, and there is no layering phenomenon after one year of storage. Compared with the molten paraffin test, under the same test conditions, the amount of paraffin microemulsion is 5kg / m 3 At this time, the water absorption thickness expansion rate of the fiberboard is reduced by 10.3%, and the static bending strength is increased by 1.6%.

Embodiment 2

[0022] Add 40kg of solid paraffin, 5kg of emulsifier octylphenol polyoxyethylene (7) ether, 2kg of sodium perfluorooctane sulfonate and 43kg of water into the emulsification tank, heat up to 90-95°C to melt the solid paraffin, and then add 10kg of The pre-prepared 7% polyvinyl formal aqueous solution is used to spontaneously emulsify the mixed system to form a milky white emulsion, and the emulsion is cooled to room temperature to obtain 100 kg of paraffin microemulsion. The average particle size of the product is 280±10nm, the stability is good, and there is no layering phenomenon after one year of storage. Compared with the molten paraffin test, under the same test conditions, the amount of paraffin microemulsion is 5kg / m 3 At this time, the water absorption thickness expansion rate of the fiberboard is reduced by 10.1%, and the static bending strength is increased by 1.5%.

Embodiment 3

[0024] Add 30kg of solid paraffin, 2kg of emulsifier nonylphenol polyoxyethylene (6) ether, 0.1kg of sodium perfluorooctane sulfonate and 62.9kg of water into the emulsification tank, heat up to 90-95°C to melt the solid paraffin, and then Add 5 kg of pre-prepared 10% polyvinyl formal aqueous solution to make the mixed system spontaneously emulsify to form a milky white emulsion, and cool the emulsion to room temperature to obtain 100 kg of paraffin microemulsion. The average particle size of the product is 280±10nm, the stability is good, and there is no layering phenomenon after one year of storage. Compared with the molten paraffin test, under the same test conditions, the amount of paraffin microemulsion is 5kg / m 3 At this time, the water absorption thickness expansion rate of the fiberboard is reduced by 10.3%, and the static bending strength is increased by 1.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com