Hot pressing process for plywood

A hot pressing process and plywood technology, applied in the direction of manufacturing tools, wood processing appliances, wood veneer bonding, etc. The effect of improving, saving labor and reducing energy consumption of hot pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

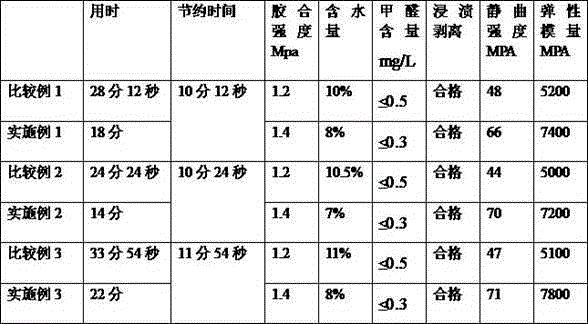

Embodiment 1

[0022] Taking a 15mm eucalyptus slab as an example, adopt the process requirements of the present invention to carry out hot pressing treatment. The water content of the veneer forming the slab is 10%, and the phenolic resin adhesive used for the slab has a solid content of 50%.

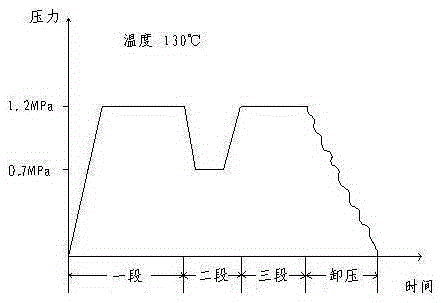

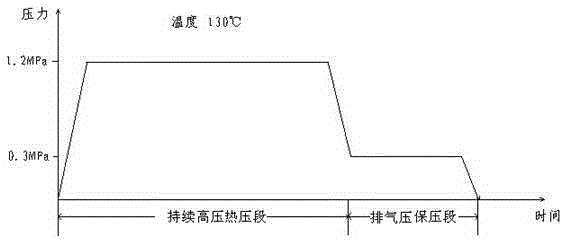

[0023] In the first hot-pressing stage, turn on the hot-pressing machine to quickly increase the pressure to a plate surface pressure of 1.2Mpa and a temperature of 130°C. It takes 1 minute and 12 seconds to carry out the first stage of heat preservation and hot-pressing of the slab. The total hot-pressing time is based on the slab The thickness is set at 58s / mm, the total time is 15mm×58s / mm=870s, and the hot-pressing time of each hot-pressing stage is one-third of the total hot-pressing time, that is, 870s÷3=290s;

[0024] In the second hot-pressing stage, when the time of the first hot-pressing stage is over, the hot-pressing machine quickly lowers the pressure to 0.7MPa on the surface of the slab,...

Embodiment 2

[0034] Take a 12mm poplar slab as an example and adopt the process requirements of the present invention to carry out hot pressing treatment. The water content of the veneers forming the slab is 13%, and the urea-formaldehyde resin adhesive used in the slab has a solid content of 45%.

[0035] In the first hot-pressing stage, turn on the hot-pressing machine to quickly raise the pressure to 0.9Mpa on the surface of the slab, and raise the temperature to 100°C. It takes 1 minute to carry out the first stage of heat preservation and hot-pressing of the slab. The total hot-pressing time is based on the thickness of the slab. 55s / mm setting, the total time is 12mm×55s / mm=660s, and the hot-pressing time of each hot-pressing stage is one-third of the total hot-pressing time, that is, 660s÷3=220s;

[0036] In the second hot-pressing stage, when the time of the first hot-pressing stage is over, the hot-pressing machine quickly reduces the pressure until the surface pressure of the slab...

Embodiment 3

[0046] Taking the 18mm birch slab as an example, adopt the process requirement of the present invention to carry out hot pressing treatment, the water content of the veneer constituting the slab is 13%, and the urea-formaldehyde resin adhesive used in the slab has a solid content of 52%.

[0047]In the first hot-pressing stage, turn on the hot-pressing machine to quickly increase the pressure to a plate surface pressure of 1.3Mpa, and raise the temperature to 120°C. It takes 1 minute and 30 seconds to carry out the first stage of heat preservation and hot-pressing of the slab. The total hot-pressing time is pressed The thickness of the slab is set at 60s / mm, the total time is 18mm×60s / mm=1080s, and the hot-pressing time of each hot-pressing stage is one-third of the total hot-pressing time, that is, 1080s÷3=360s;

[0048] In the second hot-pressing stage, when the first hot-pressing stage is over, the hot-pressing machine quickly depressurizes to a pressure of 0.8MPa on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com