A kind of ecological composite material and preparation method thereof

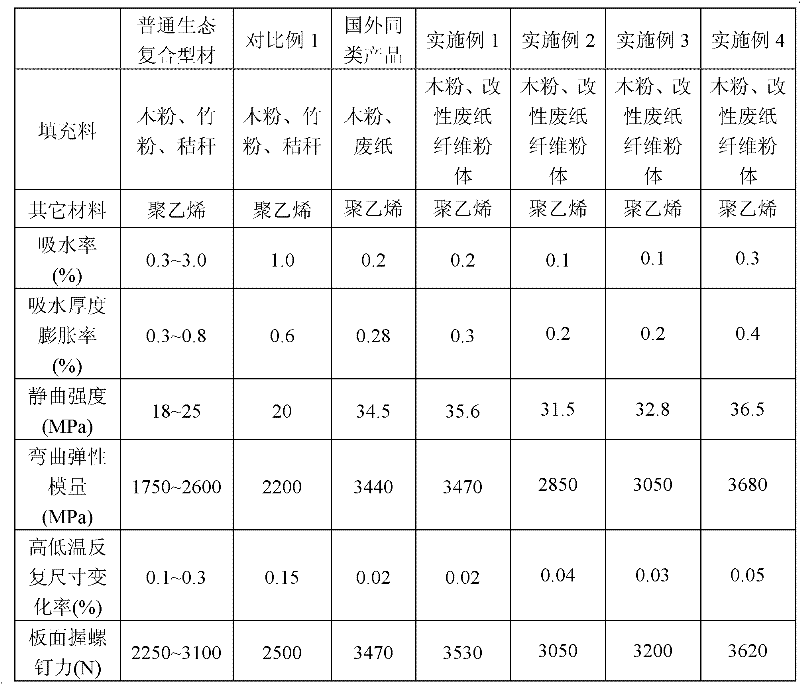

A composite material and ecological technology, applied in papermaking, paper recycling, processing waste paper, etc., can solve the problems of poor impact toughness, poor dimensional stability, and poor creep resistance, etc., to improve compatibility, Reduce material cost and good creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation method of the modified waste paper fiber powder is as follows: after the waste paper is divided into pieces, it is directly immersed in an impregnation solution (pH=5.0, adjusted by acetic acid) composed of 0.5kg vinyl silane, 94.5kg ethanol and 5kg water for 30 minutes. , filtered and drained, and modified waste paper fragments were obtained after heat treatment at a high temperature of 120°C for 30 minutes, and the modified waste paper fragments were mixed and sheared at high speed (1500rpm) in a counter-rotating double-helix mixer for 5 minutes, filtered and dried Obtain modified waste paper fiber powder with a particle size of 80 mesh to 120 mesh, such as figure 2 .

[0050] 2.0kg of wood powder with a particle size of 60 mesh to 80 mesh, 5.0kg of polyethylene, 0.1kg of EBS, 0.2kg of maleic anhydride grafted polyethylene, 0.01kg of iron oxide yellow, 0.05kg of 2-hydroxy-4-n-octoxy After the benzophenone is mixed evenly, put it in the co-rotating pa...

Embodiment 2

[0052] The preparation method of the modified waste paper fiber powder is as follows: after the waste paper is divided into pieces, it is directly immersed in an impregnation solution consisting of 5 kg of vinyl silane oligomer (SG-Si6490, Nanjing Shuguang Chemical Group Co., Ltd.), 80 kg of propanol and 15 kg of water. (pH = 4.5, adjusted by acetic acid) for 1 minute, filtered and drained, after 10 minutes of heat treatment at a high temperature of 130 ° C to obtain modified waste paper fragments, the modified waste paper fragments were mixed in a counter-rotating double-helix mixer at a high speed ( 1000 rpm) mixed and sheared for 10 minutes, filtered and dried to obtain a modified waste paper fiber powder with a particle size of 80 mesh to 100 mesh.

[0053] 0.8kg of wood powder with a particle size of 80 mesh to 100 mesh, 8kg of polyethylene, 0.02kg of EBO, 0.08kg of maleic anhydride grafted polyethylene, 0.01kg of iron oxide yellow, 0.03kg of 2-hydroxy-4-n-octyloxydi Afte...

Embodiment 3

[0055] The preparation method of the modified waste paper fiber powder is as follows: after the waste paper is divided into pieces, it is directly immersed in 0.03kg vinyl silane, 0.02 kg vinyl silane oligomer (SG-Si6490, Nanjing Shuguang Chemical Group Co., Ltd.), 99 kg Immerse in an impregnation solution (pH=5.5, adjusted by acetic acid) composed of n-butanol and 0.95kg water for 60 minutes, filter and drain, and obtain modified waste paper fragments after heat treatment at 95°C for 120 minutes. Mix and shear at high speed (2500pm) in a counter-rotating twin-screw mixer for 1 minute, filter and dry to obtain modified waste paper fiber powder with a particle size of 40 mesh to 80 mesh.

[0056] 1.0kg of wood powder with a particle size of 100 mesh to 120 mesh, 2.0kg of modified waste paper fiber powder, 7.0kg of polyethylene and 0.15kg of EBL, 0.1kg of maleic anhydride grafted polyethylene, 0.01kg of iron oxide yellow, 0.04 kg2-Hydroxy-4-n-octyloxy benzophenone is mixed evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com