Untwining and gumming device for artificial board veneer

A dipping device and wood-based panel technology, which is used in the jointing of wooden veneers, pressure impregnation, manufacturing tools, etc., can solve the problem of high density, high static bending strength, high elastic modulus and high hardness performance indicators that are difficult to meet Requirements and other issues, to achieve the effect of high elastic modulus, high static bending strength, high hardness performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

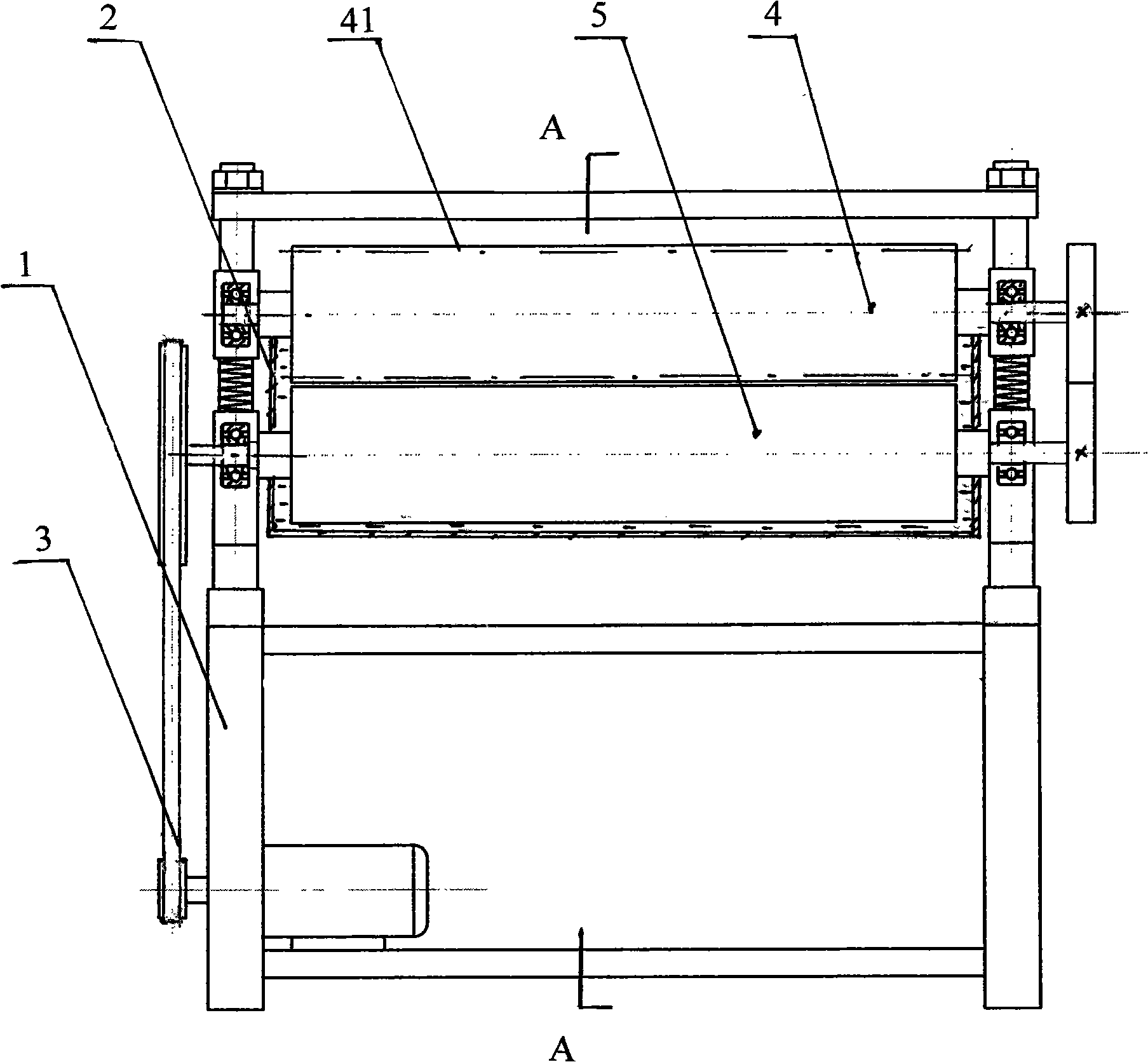

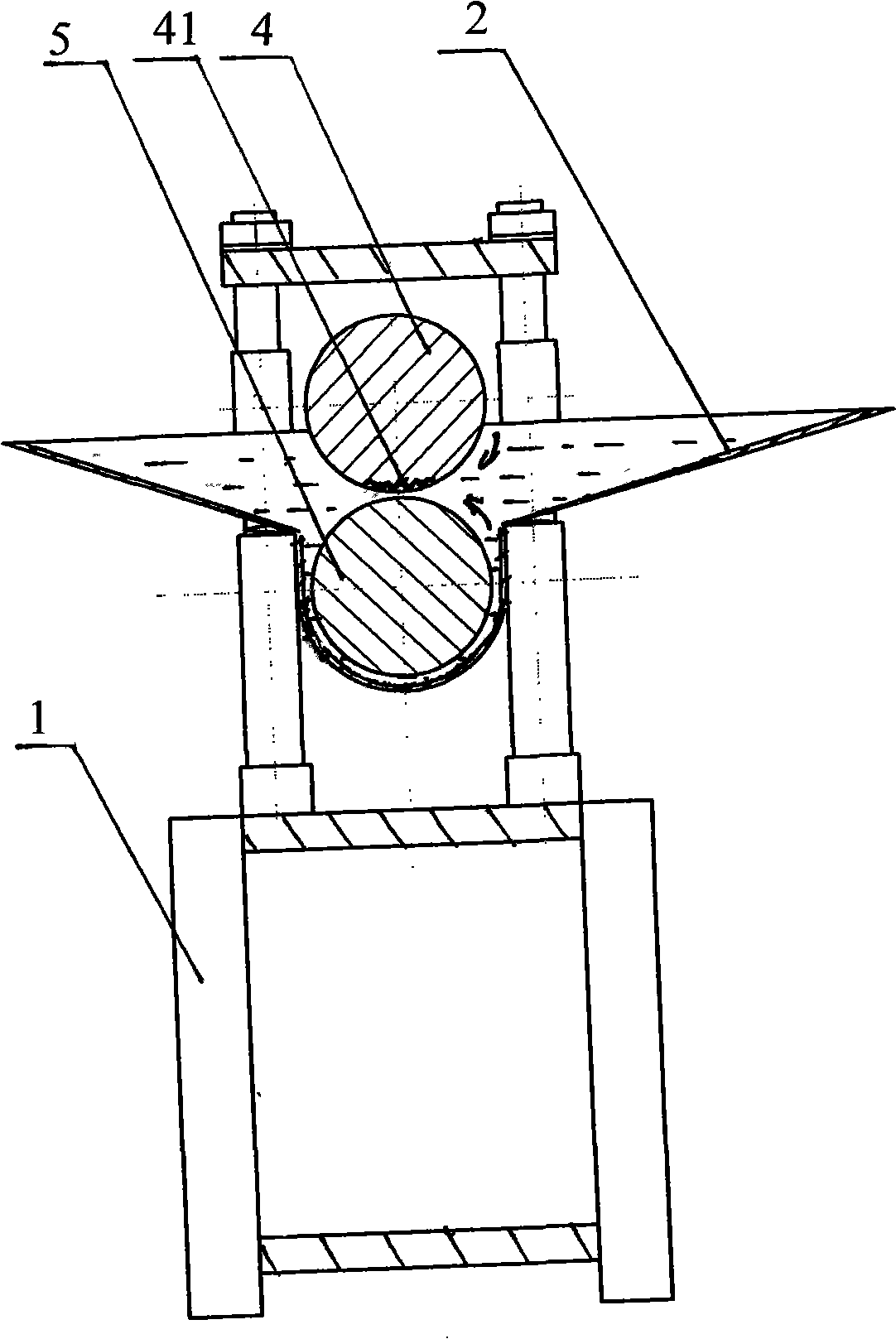

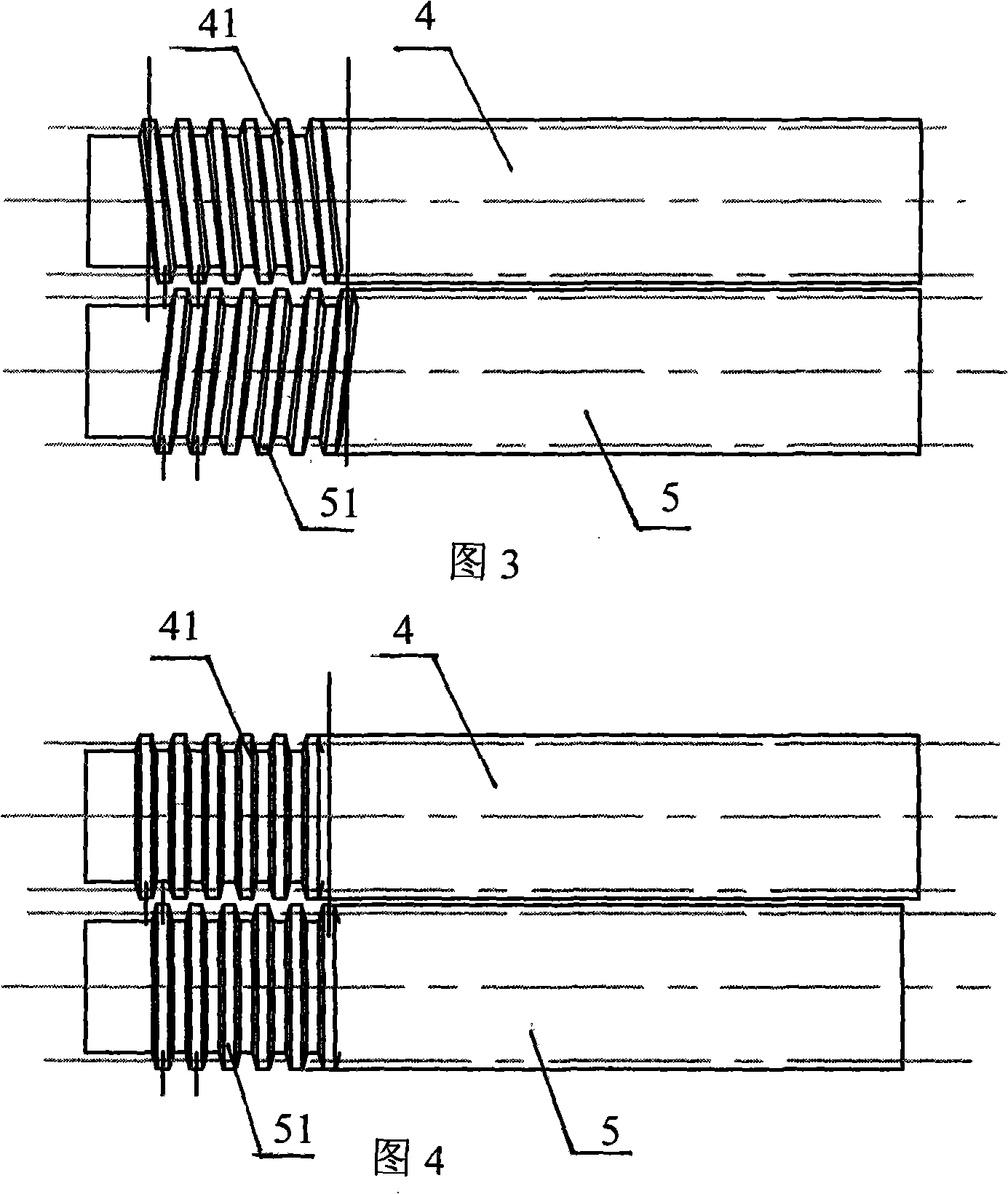

[0017] The first embodiment of the present invention is made of base 1, glue tank 2, driver 3, upper squeeze roller 4 and lower squeeze roller 5, as figure 1 , 2 shown, where:

[0018] The base frame 1 is a base supporting the rubber tank 2, the driver 3 and supporting the upper squeeze roller 4 and the lower squeeze roller 5, which belongs to the prior art;

[0019] The glue tank 2 is an open container for holding the glue, and the bottom of the entire lower squeeze roller 5 and the upper squeeze roller 4 is also in the open container, which belongs to the prior art;

[0020] The driver 3 is composed of an electric motor, a driving wheel and a driven wheel supported on the base frame 1. The motor is connected to a pulley or a sprocket as a driving wheel, and is driven to a pulley or a sprocket as a driven wheel through a closed belt or chain. sprocket, and the belt pulley or sprocket are fixedly connected to the rotating shaft end of the lower squeeze roller 5, and a pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com