Preparation method of hydrophobic oilproof paper

An oil-repellent and hydrophobic technology, applied in the field of papermaking, can solve the problems of toxic perfluorooctane sulfonamide compounds, hidden dangers of food safety and ecological environment protection, and not easy to decompose, and achieves enhanced water resistance, wide range of applicable paper types, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

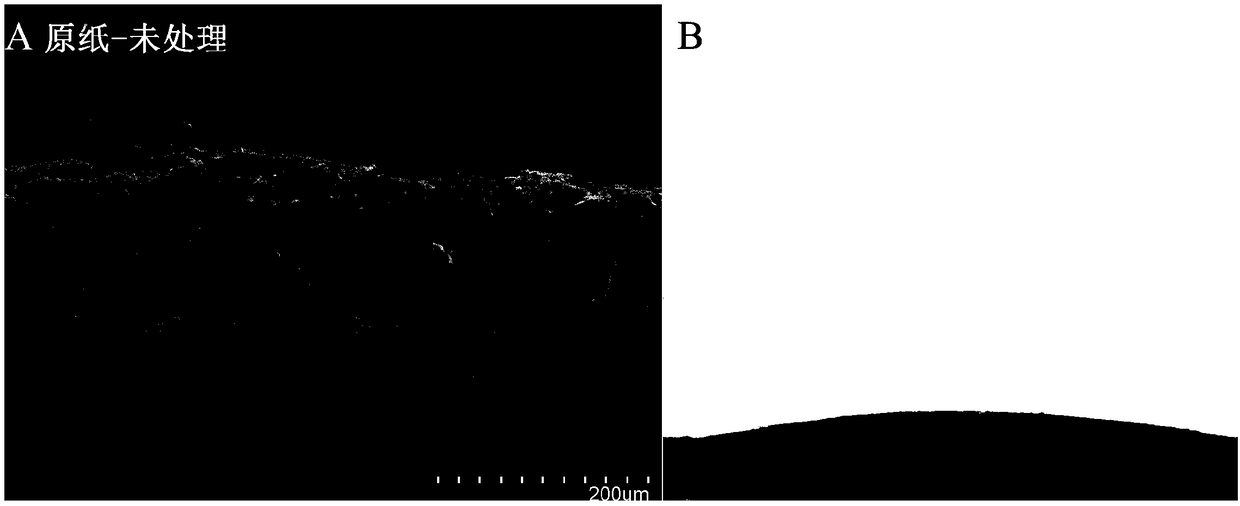

[0054] A preparation method of hydrophobic and oil-proof paper, comprising the following steps:

[0055] 1) Base papermaking: soak bleached coniferous wood chemical pulp for 3-5 hours, beat to 60-85°SR; take 40-90 parts by weight of bleached coniferous wood chemical pulp, 10-50 parts by weight of carboxymethyl cellulose , 5-30 parts by weight of bacterial cellulose, and 2-10 parts by weight of dissolving pulp are mixed, and the papermaking quantity is 50-80 g / m 2 The hand-made sheet, the pressing condition is 450-550kPa, 3-7 min, and the base paper is made after drying.

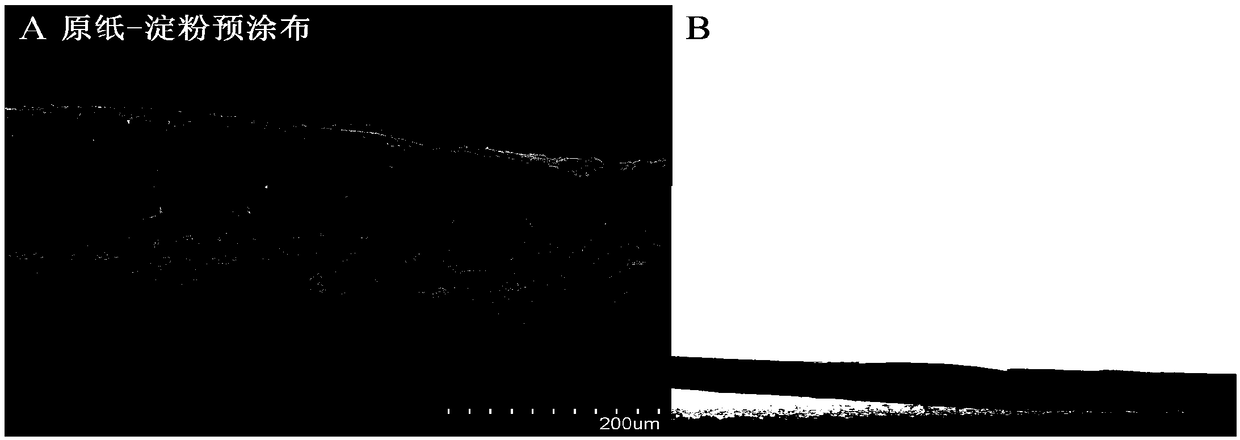

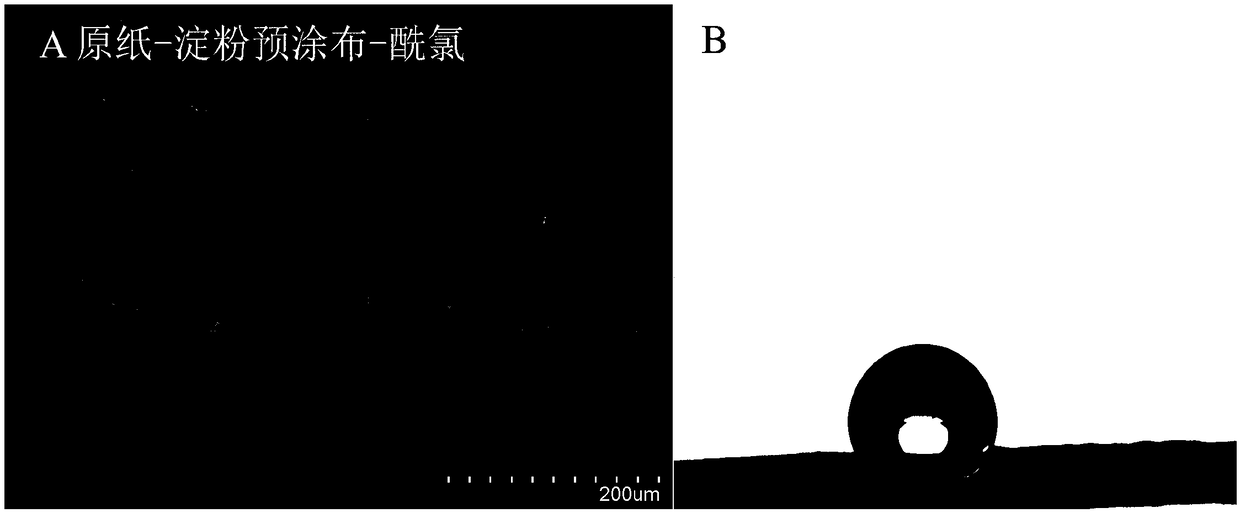

[0056] 2) Dissolve natural polyhydroxy polymer materials (starch, chitosan, guar gum, nanocellulose, polyvinyl alcohol, water-soluble ethylene-vinyl alcohol copolymer) in water, stir and heat up to 85-95°C, keep warm Until the system is transparent, then stir and cool to room temperature to obtain a coating solution with a concentration of 3-15wt%, and apply it on the surface of the paper with a coating amou...

Embodiment 1

[0070] Preparation of bacterial cellulose:

[0071] (1) Prepare culture medium

[0072] Seed medium: glucose 5 w / v%, peptone 0.5 w / v%, citric acid 0.1 w / v%, disodium hydrogen phosphate 0.2 w / v%, potassium dihydrogen phosphate 0.1 w / v%, yeast extract 0.5 w / v%, pH=6.0, sterilized at 121°C, 0.1 MPa for 30 min.

[0073] Slant medium: glucose 5 w / v%, peptone 0.5 w / v%, citric acid 0.1 w / v%, agar 2.0 w / v%, calcium carbonate 0.05 w / v%, pH=6.0, at 121°C, Sterilize at 0.1 MPa for 30 min.

[0074] Fermentation medium: glucose 5 w / v%, peptone 0.5 w / v%, citric acid 0.1 w / v%, disodium hydrogen phosphate 0.2w / v%, potassium dihydrogen phosphate 0.1 w / v%, yeast extract 0.5 w / v%, pH=6.0, sterilized at 121°C, 0.1 MPa for 30 min.

[0075] (2) Activation of strains

[0076] The bacterial species is Acetobacter xylinum, inoculate the bacterial species into the seed medium, plug the mouth of the bottle with sterilized cotton, shake gently to disperse the seeds in the medium, and then cultivat...

Embodiment 2

[0087] Similar to the method of Example 1, the difference is that the acyl chloride petroleum ether solution changes from spraying on pre-coated paper to brushing, and the resulting paper sample is detected, and its contact angle is 124.7 (2.5 °, Cobb 30 The value is 5.87 (0.3 g / m 2 , the oil resistance level is 7, the bursting strength is 225.07 (2.3 kPa, the tensile index is 11.08 (0.4 N m / g), and the surface strength is greater than 4 m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface strength | aaaaa | aaaaa |

| Bursting strength | aaaaa | aaaaa |

| Tensile index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com