Paper-making technique employing bio-fermentation pulping method instead of chemical pulping technique

A papermaking process and biological fermentation technology, which is applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems such as the inability to completely cancel the chemical pulping process, the large investment in recycling equipment, and the increase in production costs, and can eliminate the chemical pulping process. , The effect of improving the quality of papermaking and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

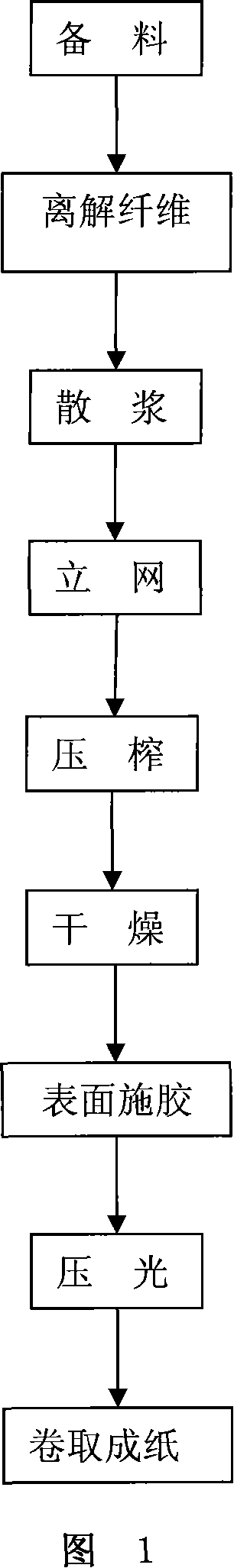

[0044] A kind of papermaking process method that replaces chemical pulping process with bio-fermentation pulping method, it comprises pulping, papermaking process section, wherein the pulping section is (1) stock preparation and (2) dissociated fiber steps of following steps; Papermaking The section is (3) loose pulp in the following steps; (4) vertical net; (5) pressing; (6) drying; (7) surface sizing; (8) calendering; The processing method is as follows:

[0045] (1) material preparation: wood is pulverized into 40~80 mesh particles, adding weight is 2% wheat bran and 7% dry bean dregs of wood gross weight, then adding weight is 20% water of wood gross weight and stirs evenly;

[0046] (2) Dissociated fibers: put the above mixture into a cooking pot and cook and sterilize it at 120° C. for 10 minutes, take it out, add aspergillus flavus whose weight is 0.05% of the total weight of wood after cooling, stir evenly, and place it in a fermenter. The thickness is 300cm; ferment fo...

Embodiment 2

[0055] A kind of papermaking process method that replaces chemical pulping process with bio-fermentation pulping method, it comprises pulping, papermaking process section, wherein the pulping section is (1) stock preparation and (2) dissociated fiber steps of following steps; Papermaking The technology of the prior art can be adopted for the technology of the section from loose pulp to coiling into paper. The concrete processing method of described step (1), (2) is:

[0056] (1) material preparation: wood and waste bagasse are pulverized together into 100 mesh particles, adding weight is 7% wheat bran and 5% dry bean dregs of the total weight of wood and waste bagasse, then adding weight is wood and waste bagasse 70% water of the total weight is stirred evenly;

[0057] (2) Dissociated fiber: put the above mixture into a cooking pot, cook and sterilize at 100°C for 30 minutes, take it out, and add a combination of Aspergillus flavus and Monascus whose weight is 0.15% of the t...

Embodiment 3

[0059] A kind of papermaking process method that replaces chemical pulping process with bio-fermentation pulping method, it comprises pulping, papermaking process section, wherein the pulping section is (1) stock preparation and (2) dissociated fiber steps of following steps; Papermaking The section is (3) loose pulp in the following steps; (4) vertical net; (5) pressing; (6) drying; (7) surface sizing; (8) calendering; The processing method is as follows:

[0060] (1) Prepare materials: crush reeds and cotton stalks together into 50-60 mesh particles, add 5% wheat bran and 5% dry bean dregs with a weight equal to the total weight of reeds and cotton stalks, 50% water by weight is stirred evenly;

[0061] (2) Dissociated fibers: put the mixture into a cooking pot, cook and sterilize it at 110° C. for 20 minutes, take it out, and add the Aspergillus flavus and Aspergillus oryzae compositions whose weight is 0.1% of the total weight of reeds and cotton stalks after cooling, St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com