Pulping system and pulping method for environment-friendly mechanical pulp and chemical mechanical pulp of non-woody crops

A technology of chemical machinery and crops, applied in pulping of cellulose raw materials, textile and papermaking, separation of raw materials, etc., can solve the problems of poor biodegradability, large discharge of intermediate waste liquid, difficult conversion treatment, etc., and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

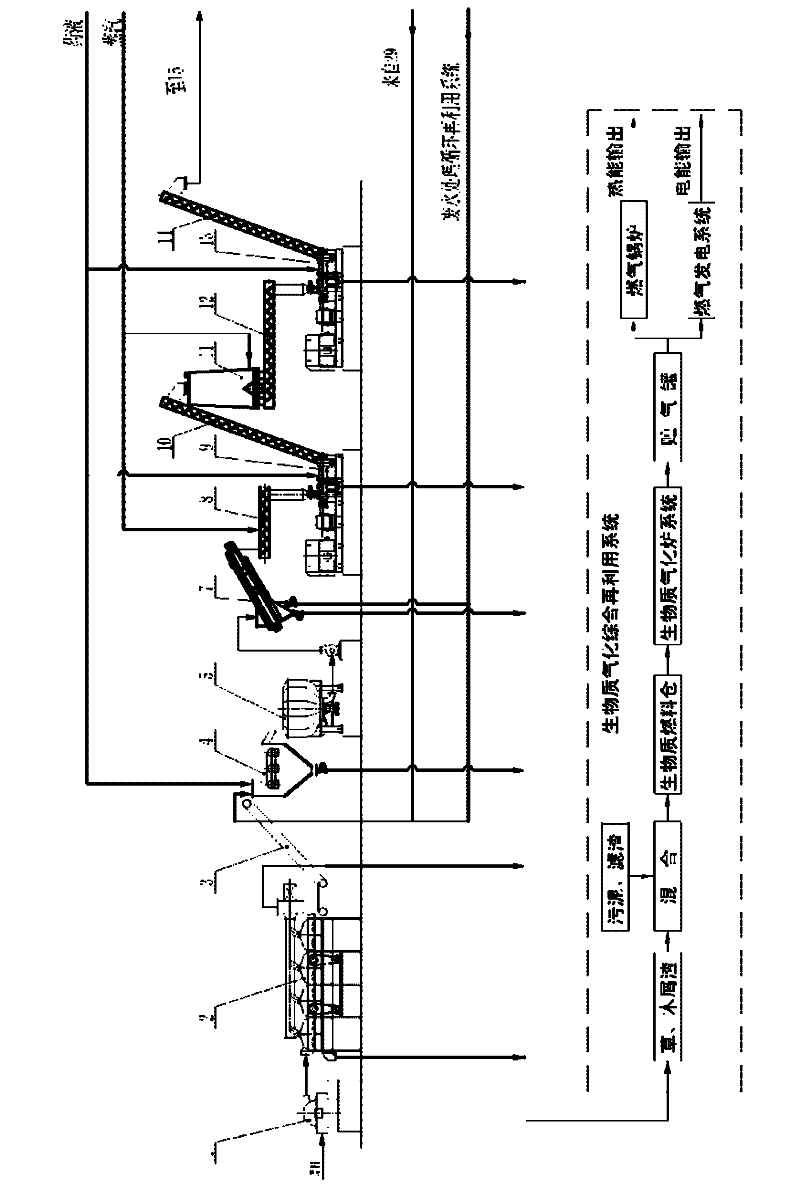

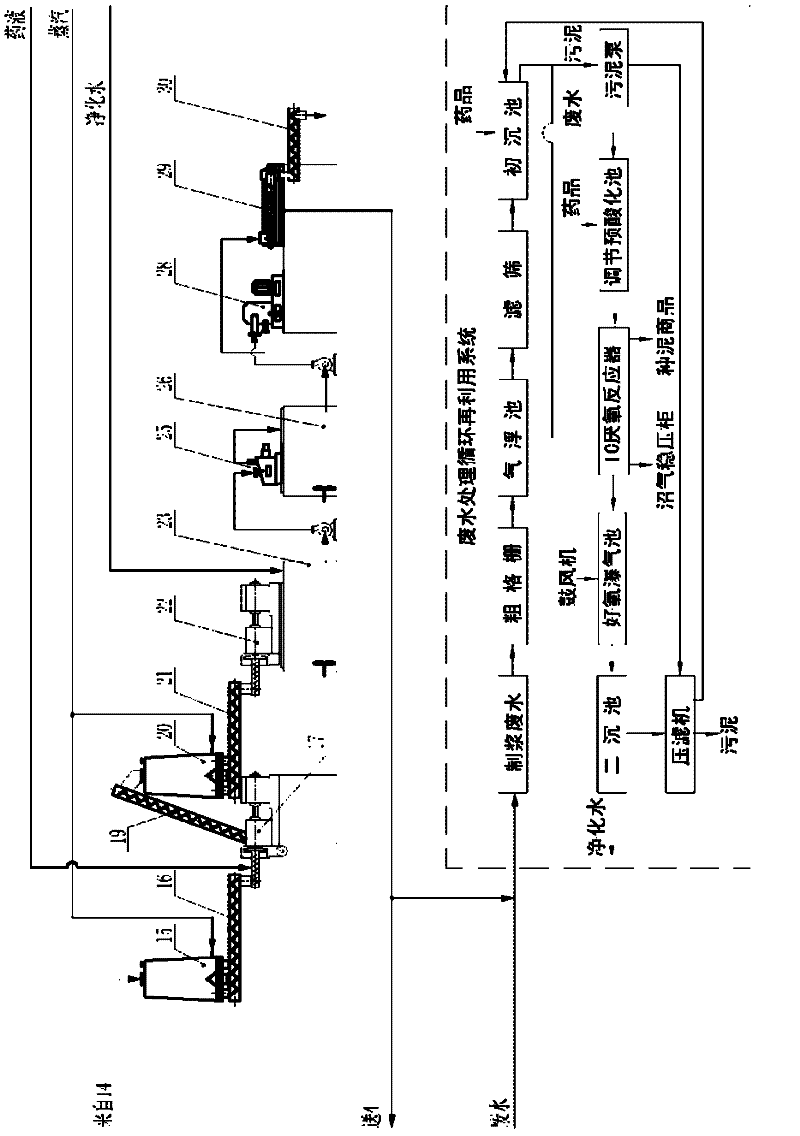

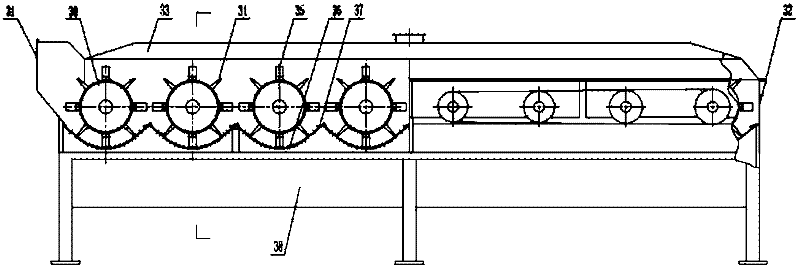

[0051] Using straw as raw material to make mechanical natural color paste

[0052] The raw materials are cut by the knife-roller grass cutter 1 and enter the hammer wire dust collector 2. The waste slag that is screened out is sent to the waste residue biomass gasification comprehensive reuse system by the collection and transportation equipment, and the raw materials are sent to the waste residue biomass gasification comprehensive reuse system through the transportation equipment 3. In the multi-roller sand and gravel metal collector of the immersion washer 4, the raw materials are pre-washed by the action of multi-roller paddles and water flow, and the washing water temperature is 75°C, and the large sandstone or metal sundries entrained in the raw materials are removed. The specific heavy foreign matter is removed, falling into the bottom slag collection tank and discharged out of the machine regularly, and the material flows into the hydraulic prepreg machine as the immersi...

Embodiment 2

[0056] Bleached pulp made from wheat straw or straw

[0057] The raw materials are cut by the knife-roller grass cutter 1, and then enter the hammer wire dust collector 2. The waste slag that is screened out is sent to the biomass gasification comprehensive reuse system by the collection and transportation equipment, and the raw materials are sent into the biomass gasification comprehensive reuse system through the transportation equipment 3. In the multi-roller sand and gravel metal collector as the dipping washer 4, the raw materials are pre-washed through the action of the multi-roller paddle and water flow, and the pre-soaking agent is added to the washing water. The pre-soaking agent contains JFC0.05%, Sodium dodecylbenzenesulfonate 0.05% and sodium hydroxide 0.3%, liquid ratio 1:20, washing water temperature 75°C, accelerate penetration, swell raw material fibers, and remove large sandstone or metal debris entrained in raw materials Equally large foreign matters are remo...

Embodiment 3

[0062] Making Bleached Pulp Using Bagasse as Raw Material

[0063]The raw material has become slag-like during the sugar making process, so the raw material is directly sent to the hammer wire dust collector 2 for pitting treatment through the belt conveyor, and the screened sugarcane pith and slag are sent to the waste slag production line by the collection and transportation equipment. Material gasification system, the raw material is sent to the multi-roller sand and gravel metal collector as the impregnated washer 4 through the conveying equipment 3, and the raw material is pre-washed by the action of the multi-roller paddle and water flow, and the pre-soaked water is added to the washing water The agent contains: JFC 0.05%, sodium dodecylbenzene sulfonate 0.05% and sodium hydroxide 0.5%, the liquid ratio is 1:20, the washing water temperature is 75°C, and the large sandstone or metal debris entrained in the raw materials The foreign matters of equal proportion are removed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com