Production process of antibacterial paper and antibacterial paper

A production process and technology of antibacterial paper, applied in the production process of antibacterial paper and the field of antibacterial paper, can solve the problems of reducing the content of antibacterial agent in antibacterial paper, increasing the production cost of antibacterial paper, and waste of antibacterial agent, so as to improve retention rate and good Paper strength, antibacterial performance, and strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

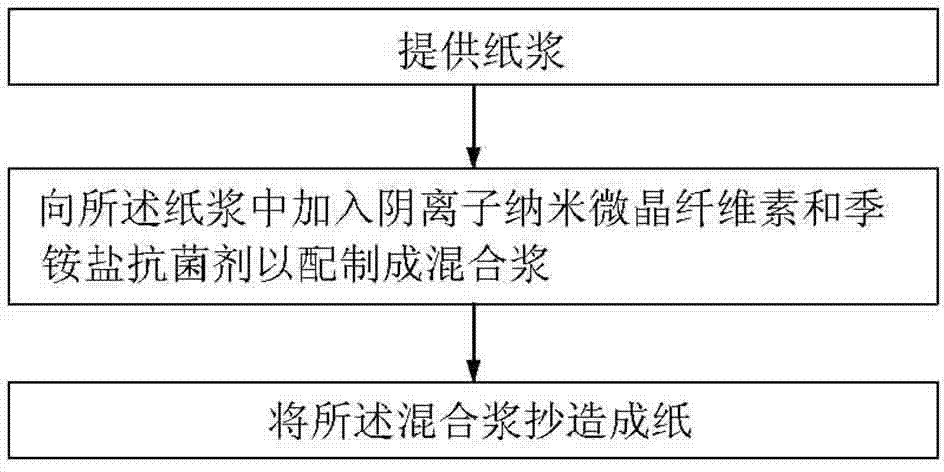

[0009] Such as figure 1 As shown, the antibacterial paper production process that the embodiment of the present invention provides comprises the following steps:

[0010] Pulp is provided; anionic nano-microcrystalline cellulose and quaternary ammonium antibacterial agent are added to the pulp to prepare mixed pulp; and the mixed pulp is made into paper.

[0011] In the above-mentioned antibacterial paper production process provided by the present invention, according to different paper requirements, the type of pulp can be wood pulp, straw pulp, hemp pulp, reed pulp, cane pulp, bamboo pulp, rag pulp, etc. Commonly used papermaking raw materials.

[0012] In the present invention, the quaternary ammonium salt antibacterial agent may be a single quaternary ammonium salt antibacterial agent or a polyquaternary ammonium salt antibacterial agent having at least two quaternary ammonium salt cationic groups.

[0013] Preferably, the quaternary ammonium salt antibacterial agent is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com