Lignin-modified phenolic foam and preparation method thereof

A technology of phenolic foam and lignin, which is applied in the field of lignin-modified phenolic foamed plastics, can solve the problems of slag removal and poor phenolic foam toughness, and achieves the effects of cost reduction, foam toughness improvement and dependency reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

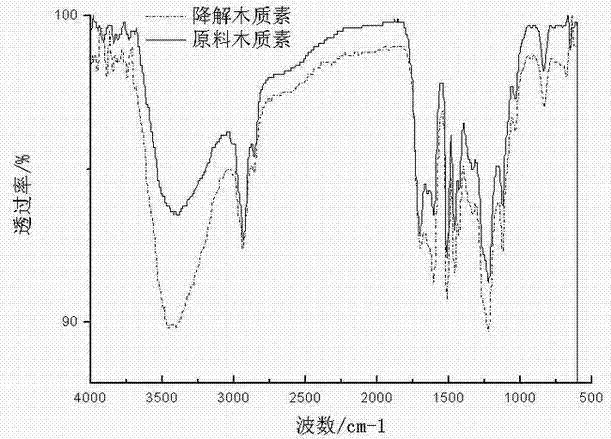

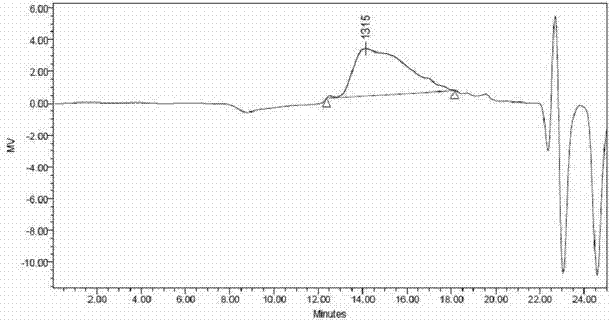

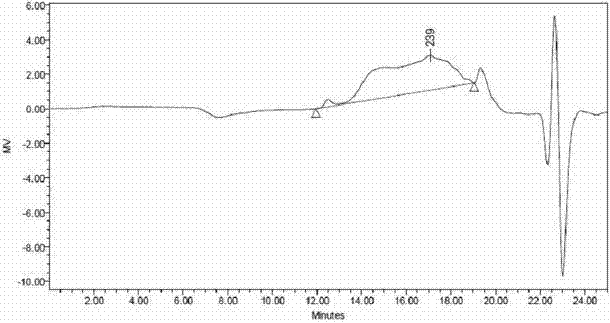

Method used

Image

Examples

Embodiment 1

[0036] Dissolve 25g of acid-hydrolyzed lignin (20% substitute for phenol) in 30g of water, add aqueous sodium hydroxide solution to adjust the pH to 8, connect the ozone generator, and react at 50°C for a period of time. Adjust the temperature to 80-85°C, add 60% phenol and 50% formaldehyde (phenol-formaldehyde molar ratio 1:1.7), pH to 8.5, after a certain period of reaction, add the remaining phenol and formaldehyde, pH to 8.5, and then react for a certain period of time and heat up to 90°C, continue to react until the viscosity is suitable, cool down to 80°C, neutralize with acetic acid to pH 6-7, dehydrate under reduced pressure to a solid content of 80%, and obtain lignin-modified resole phenolic resin. The resin is blended with n-pentane, hydrochloric acid and Tween-80 to foam and solidify to obtain lignin modified phenolic foamed plastics.

[0037] Lignin modified phenolic foam properties: density 80-30kg / cm 3 ; Closed cell rate ≥ 80%; its compressive strength (compre...

Embodiment 2

[0042] 42.9g of corn cob alkali lignin (30%wt instead of phenol) was dissolved in 40g of water, and the pH was adjusted to 8 by adding sodium hydroxide aqueous solution, connected to the ozone generator, and reacted at 50°C for a period of time. Adjust the temperature to 80-85°C, add 60% phenol and 50% formaldehyde (phenol-formaldehyde molar ratio 1:1.7), pH to 8.5, after a certain period of reaction, add the remaining phenol and formaldehyde, pH to 8.5, and then react for a certain period of time and heat up to 90°C, continue to react until the viscosity is suitable, cool down to 80°C, neutralize with hydrochloric acid to pH 6-7, and dehydrate under reduced pressure to a solid content of 80%, to obtain a lignin-modified resole phenolic resin. The resin is blended with n-pentane, hydrochloric acid and Tween-80 to foam and solidify to obtain lignin modified phenolic foamed plastics.

[0043]

Embodiment 3

[0045] Dissolve 42.9g of kraft lignin (30% substitute for phenol) in 40g of water, add potassium hydroxide aqueous solution to adjust the pH to 8, connect the ozone generator, and react at 50°C for a period of time. Adjust the temperature to 80-85°C, add 60% phenol and 50% formaldehyde (phenol-formaldehyde molar ratio 1:1.5), pH to 8.5, react for a certain period of time, add the remaining phenol and formaldehyde, pH to 8.5, then react for a certain period of time and heat up to 90°C, continue to react until the viscosity is suitable, cool down to 80°C, neutralize with acetic acid to pH 6-7, dehydrate under reduced pressure to a solid content of 80%, and obtain lignin-modified resole phenolic resin. The resin is blended with n-pentane, hydrochloric acid and Tween-80 to foam and solidify to obtain lignin modified phenolic foamed plastics.

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| dimensional stability | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com