Composite air filtering material for filtering bag and preparation method thereof

An air filter material and filter bag technology, applied in the direction of filtration separation, separation method, dispersed particle filtration, etc., can solve the problems of low carbon content, high cost, and secondary environmental pollution of activated carbon cloth, and achieve good air permeability and low cost. The effect of filtration resistance and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

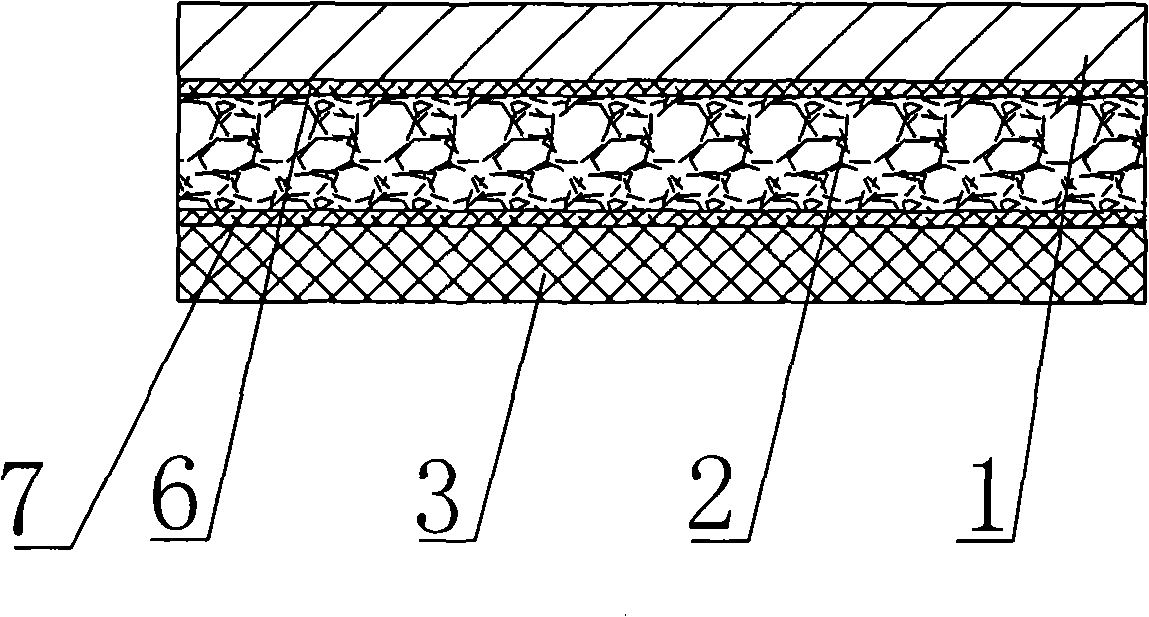

[0050] Refer to figure 1 , A composite air filter material for filter bags, comprising a protective layer 1, a deodorizing layer 2, a filter layer 3. The protective layer 1 and the filter layer 3 are compounded with the two sides of the deodorizing layer 2 respectively;

[0051] The protective layer is 40g / m 2 Antibacterial polypropylene spunbond non-woven fabric;

[0052] The deodorizing layer adopts a weight of 50g / m 2 Deodorizing powder, the weight ratio of each component in the deodorizing powder is 30% activated carbon, 20% zeolite, and 50% sodium bicarbonate;

[0053] The filter layer is 40g / m 2 Polypropylene meltblown non-woven fabric.

[0054] An adhesive layer 6 is provided between the protective layer 1 and the deodorizing layer 2. An adhesive layer 7 is provided between the filter layer 3 and the deodorizing layer 2.

[0055] When preparing, put the protective layer material on the feeding rack, spray and apply the adhesive, and then spread the deodorant powder evenly ...

Embodiment 2

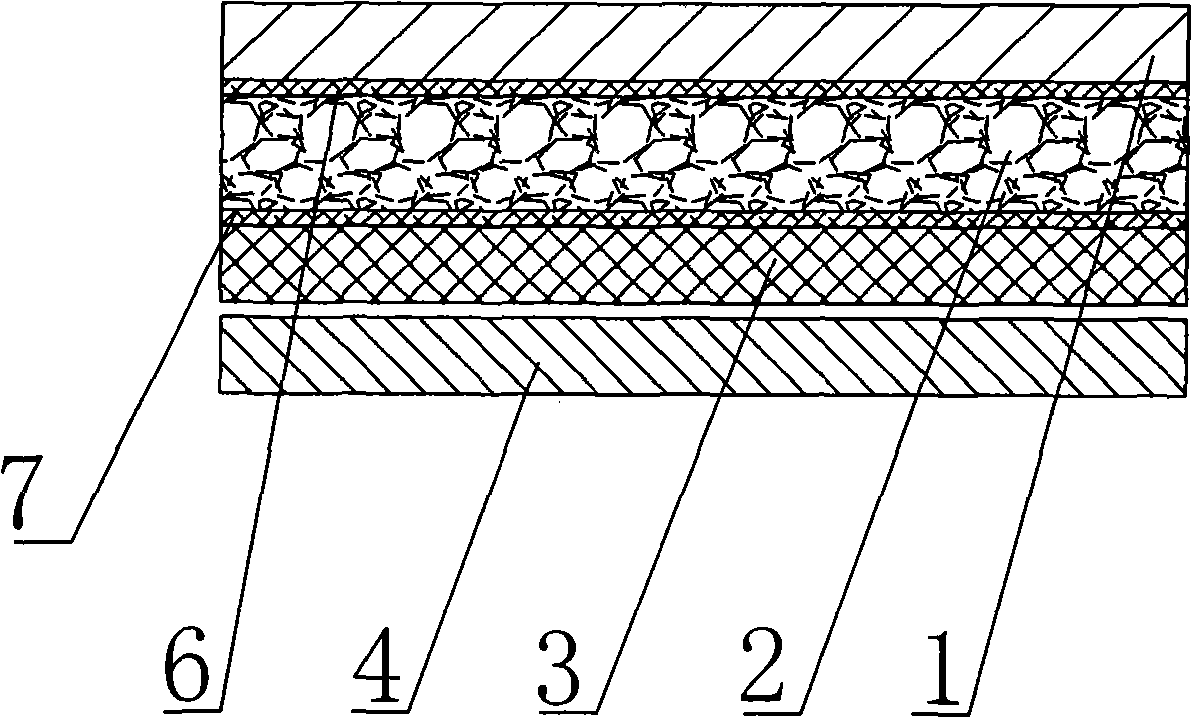

[0057] Refer to figure 2 , A composite air filter material for filter bags, comprising a protective layer 1, a deodorizing layer 2, a filter layer 3. The protective layer 1 and the filter layer 3 are compounded with the two sides of the deodorizing layer 2 respectively;

[0058] The protective layer is 40g / m 2 Antibacterial polypropylene spunbond non-woven fabric;

[0059] The deodorizing layer adopts a weight of 50g / m 2 Deodorant powder, the weight ratio of each component in the deodorant powder is 30% activated carbon, 20% zeolite, 50% sodium bicarbonate;

[0060] The filter layer is 40g / m 2 Polypropylene meltblown non-woven fabric.

[0061] An adhesive layer 6 is provided between the protective layer 1 and the deodorizing layer 2. An adhesive layer 7 is provided between the filter layer 3 and the deodorizing layer 2.

[0062] The filter layer 3 is also compounded with a first dust-holding layer 4. The first dust-holding layer adopts a weight of 40g / m 2 Hot air non-woven fabric...

Embodiment 3

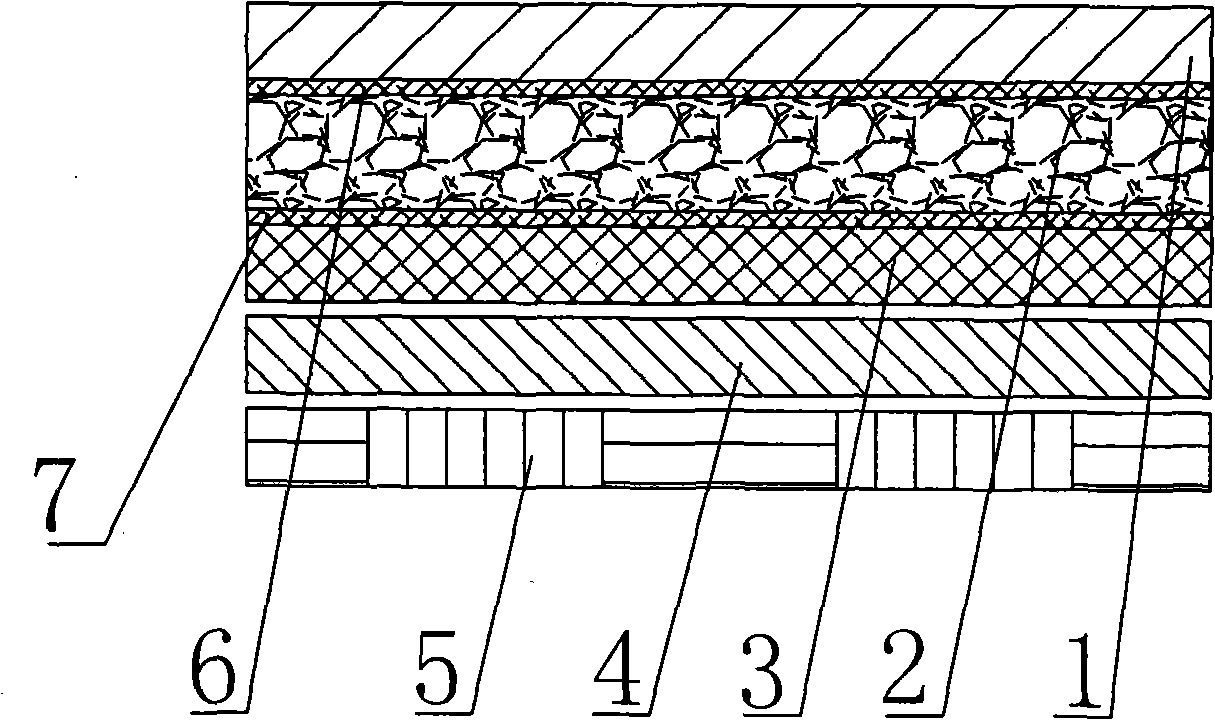

[0065] Refer to image 3 , A composite air filter material for filter bags, comprising a protective layer 1, a deodorizing layer 2, a filter layer 3. The protective layer 1 and the filter layer 3 are compounded with the two sides of the deodorizing layer 2 respectively;

[0066] The protective layer is 40g / m 2 Antibacterial polypropylene spunbond non-woven fabric;

[0067] The deodorizing layer adopts a weight of 50g / m 2 Deodorant powder, the weight ratio of each component in the deodorant powder is 30% activated carbon, 20% zeolite, 50% sodium bicarbonate;

[0068] The filter layer is 40g / m 2 Polypropylene meltblown non-woven fabric.

[0069] An adhesive layer 6 is provided between the protective layer 1 and the deodorizing layer 2. An adhesive layer 7 is provided between the filter layer 3 and the deodorizing layer 2.

[0070] The filter layer 3 is also compounded with a first dust-holding layer 4. The first dust-holding layer adopts a weight of 40g / m 2 Hot air non-woven fabric....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com