Prepn process of active defoaming agent composition

A composition and active technology, applied in the direction of foam dispersion/prevention, etc., can solve the problems of unsatisfactory foam suppressing performance and unsatisfactory foam suppressing activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

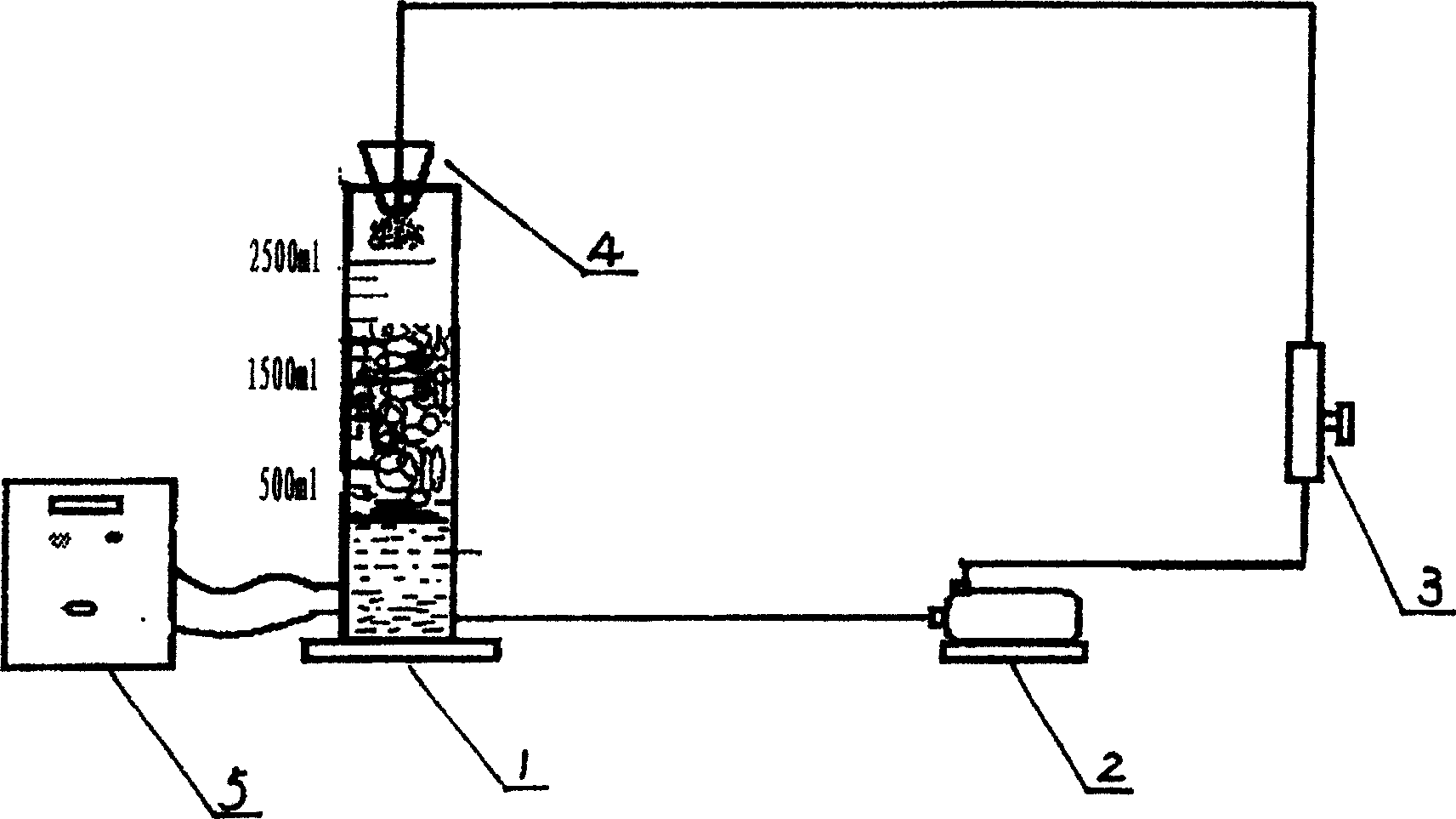

Image

Examples

Embodiment 1

[0026] (1) Preparation of antifoaming active composition:

[0027] Add 2000g of silicone oil with a viscosity of 100,000MPa·s, 200g of MQ resin (M / Q ratio of 0.40:1.00), 20g of catalyst A (note: prepared by the reaction of KOH and methyl silicone oil) into a 5L vacuum mixer, and heat up to 100 Add 100g of hydrophobic white carbon black and 30g of methyltriethoxysilane after polymerization of the reactants at -150°C, stir well, and control the temperature of the reaction system at 100-120°C for 4 hours, and finally at 160°C with a vacuum of 0.03 When -0.05MPa, react for another 2 hours to make the reaction complete. Then it was cooled to room temperature to obtain a white cross-linked antifoaming active composition.

[0028] (2) Preparation of emulsion type defoamer:

[0029] Add 250g Span, 100g Tween, 800g223 polyether, 700g400 polyether to the antifoaming active composition prepared above, heat to 70°C under continuous vigorous stirring, slowly add 1200g water, and then add...

Embodiment 2

[0032] (1) Preparation of antifoaming active composition:

[0033] Add 2000g of silicone oil with a viscosity of 200,000MPa·s, 100g of MQ resin (M / Q ratio of 1.0:1.0), 20g of catalyst B (note: prepared by the reaction of NaOH and methyl silicone oil) into a 5L vacuum mixer, and heat up to 80- Add 100g of hydrophobic white carbon black and 30g of hexamethyldisilazane after the reaction material is cross-linked at 140°C, stir well, and control the temperature of the reaction system at 90-110°C for 4 hours. At 0.05MPa, react for another 2h to make the reaction complete. Then it was cooled to room temperature to obtain a white polymeric defoaming active composition.

[0034] (2) Preparation of solvent-based defoamer:

[0035] Add 100 g of the above-prepared silicone active composition into 200 g of diethylene glycol and raise the temperature to 100-105° C. for 1 hour to fully dissolve it, and then the defoamer B with excellent defoaming and antifoaming properties can be prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com