Reconstituted tobacco and heated non-combustible cigarette prepared by using same

A heat-not-burn and reconstituted tobacco leaf technology, which is applied in the preparation of tobacco, smoker’s products, tobacco, etc., can solve problems such as many reconstituted tobacco leaves that have not been seen yet, achieve good practical value and promotion and application significance, and meet psychological and physiological needs , good versatility and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

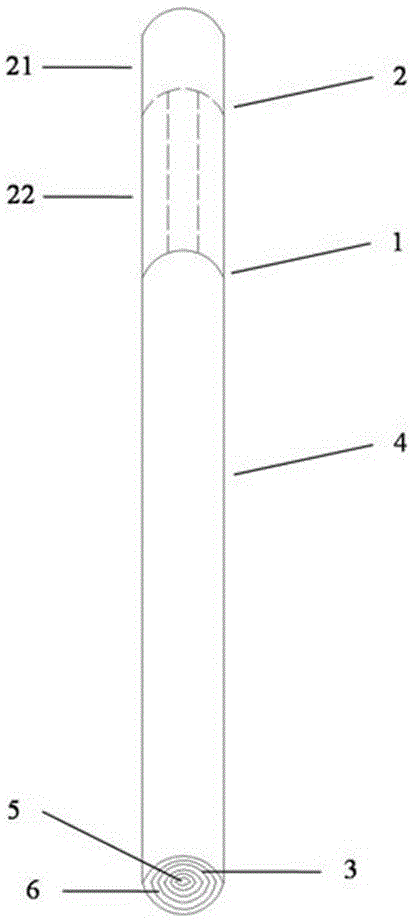

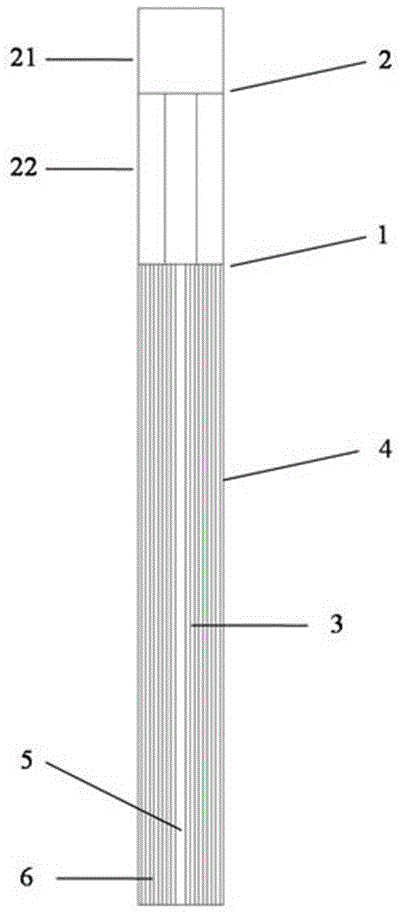

[0032] One of the main innovations of the present invention lies in the structural form of the prepared cigarette. Therefore, the structural form of the heat-not-burn cigarette prepared in the present invention is briefly introduced as follows.

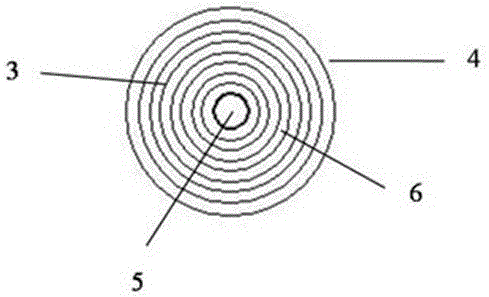

[0033] Such as Figure 1~3 As shown, the heat-not-burn cigarette 1 prepared by using reconstituted tobacco leaves provided in the present invention includes a chimney 3, a cigarette paper 4 wrapped outside the chimney, and a composite filter rod 2 connected to one end of the chimney;

[0034] The chimney 3 is prepared from reconstituted tobacco leaves, and the center of the chimney is a cavity 5, the diameter of which can be adjusted between 1 and 5 mm according to requirements; there is a layer gap (gap) 6 between two adjacent layers of reconstituted tobacco leaves, The layer gap is basically kept between 0~0.5mm;

[0035]The composite filter rod 2 includes a hollow section 22 and a solid section 21, the inner diameter / outer diamete...

Embodiment 2

[0038] Another main innovation point of the present invention lies in the chimney prepared by using reconstituted tobacco leaves, which is briefly introduced as follows.

[0039] The reconstituted tobacco leaf described in the present invention is prepared by papermaking to prepare the tobacco sheet base, and then coated with flavoring and dried. The raw materials are calculated in mass percentage, specifically:

[0040] Tobacco sheet base raw materials: 50 mesh tobacco leaf powder 15%, tobacco stem fiber with a fiber length not less than 1mm 45%, filler calcium carbonate 10%, paper-making additives 3%;

[0041] Coating material: tobacco extract 6%, polyol and polyol ester 18%, essence 3%;

[0042] The calcium carbonate particle size of the filler is about 5 μm;

[0043] Described papermaking aid is guar gum;

[0044] The tobacco extract is ethanol extract of tobacco;

[0045] Described polyol and polyol ester are following mass ratio mixture, propylene glycol: glycerol: gl...

Embodiment 3

[0052] The method for preparing reconstituted tobacco leaves provided in this example is the same as that in Example 2, only some parameters are adjusted as follows.

[0053] The raw material ratio of reconstituted tobacco leaves is as follows:

[0054] Tobacco base material: 20% of 60-mesh tobacco leaf powder, 50% of tobacco stem fiber with a fiber length of not less than 1mm, 6% of filler calcium carbonate, and 5% of paper-making additives;

[0055] Coating material: tobacco extract 8%, polyol and / or polyol ester (propylene glycol: glycerol: glyceryl acetate = 1:3:1) 9%, essence 2%.

[0056] Adjust the specifications of the chimney made by the reconstituted tobacco leaves as follows: the diameter of the chimney cavity is 3 mm, and the layer gap is about 0.2 mm.

[0057] Utilize conventional cigarette rolling equipment to roll the chimney tube, composite filter rod and cigarette paper into the heat-not-burn cigarette designed in the present invention; in order to adapt to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com