Modified solid electrolyte membrane, preparation method thereof and lithium battery

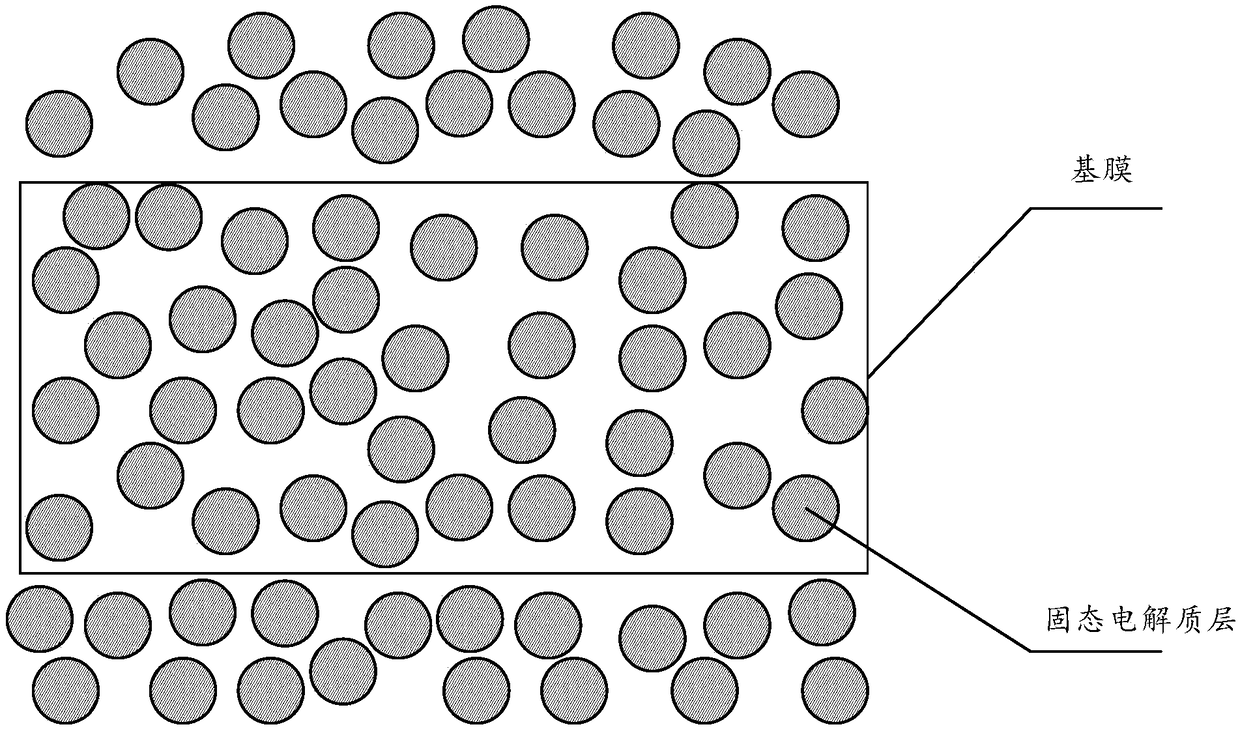

A technology of solid electrolyte membrane and solid electrolyte, applied in the direction of non-aqueous electrolyte batteries, solid electrolytes, electrolytes, etc., can solve the problems of reducing battery energy density, increasing battery internal resistance, etc., and achieve good liquid absorption, uniform thickness, and ion conductivity high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

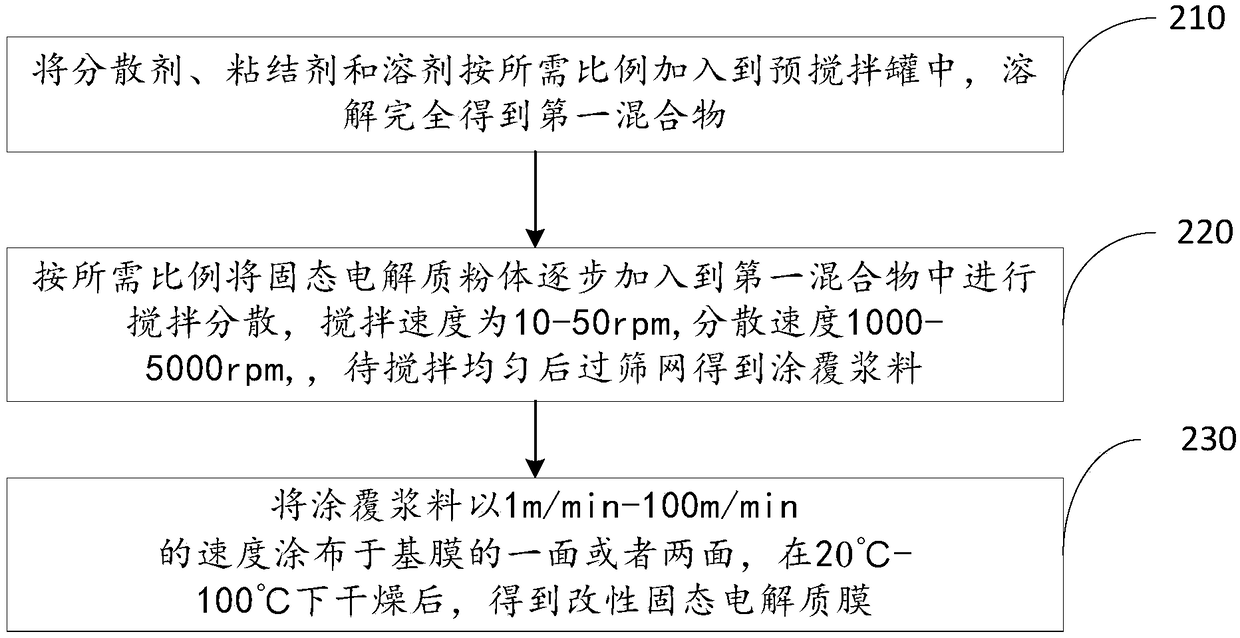

[0033] The preparation method of the modified solid electrolyte membrane provided in this embodiment, its steps are as follows figure 2 shown, including the following steps:

[0034] Step 210, adding the dispersant, binder and solvent into the pre-mixing tank according to the required ratio, and completely dissolving to obtain the first mixture;

[0035] Wherein, the solvent is at least one of water, N-methylpyrrolidone, N,N-dimethylformamide, acetone and acetonitrile;

[0036]When the solvent is water, the binder is styrene-butadiene latex, styrene-acrylic latex, polyvinyl alcohol, polyacrylamide, polymethyl methacrylate-butyl acrylate, hydroxyethyl cellulose, methyl hydroxyethyl cellulose , sodium carboxymethylcellulose, and polyacrylamide; the dispersant is sodium polyacrylate, sodium dodecylbenzenesulfonate, sodium lauryl sulfate, sodium hexametaphosphate, polyacrylic acid, One or more of cetyltrimethylammonium bromide, polyethylene glycol, potassium polyacrylate, octyl...

Embodiment 1

[0046] This embodiment provides a modified solid electrolyte membrane, which includes a base membrane and a solid electrolyte layer composed of a coating slurry coated on one side of the base membrane, wherein the base membrane is a polypropylene porous membrane with a thickness of 10um. The surface coating method, the coating thickness is 3um, and the coating slurry used to form the solid electrolyte layer is: 20% composition, 80% deionized water according to the mass ratio; wherein, the composition is prepared according to the mass ratio: nano solid Electrolyte lithium titanium aluminum phosphate Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 Powder 97%, particle size D50 is 200nm, binder sodium carboxymethyl cellulose 1%, styrene-butadiene latex 1%, dispersant: sodium polyacrylate 1%, octylphenol polyoxyethylene 1%.

[0047] The modified solid electrolyte membrane in this example is prepared by the following method, which specifically includes steps:

[0048] (1) Add the binder sodium...

Embodiment 2

[0054] This embodiment provides a modified solid electrolyte ceramic membrane, which includes a base membrane and a solid electrolyte layer composed of a coating slurry coated on one side of the base membrane. The base film is a polypropylene porous film with a thickness of 12um. It is coated on one side with a coating thickness of 4um. The coating slurry used to form the solid electrolyte layer is: 20% of the composition, N-methylpyrrolidone 80%; wherein, the preparation of the composition is according to the mass ratio: nanometer solid electrolyte lithium titanium aluminum phosphate Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 Powder 96%, particle size D50 is 200nm. Binder: polyvinylidene fluoride 2%, dispersant: glyceryl stearate 2%.

[0055] The method for preparing the modified solid electrolyte membrane is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com