Method for preparing super absorbent resin with cross-linked structure by using potato starch as raw material

A technology of potato starch and superabsorbent resin, which is applied in the field of superabsorbent resin, can solve the problems of small variety and quantity, poor salt resistance, low gel strength, etc., to improve the state after water absorption, enhance the adsorption capacity, and absorb liquid The effect of good ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

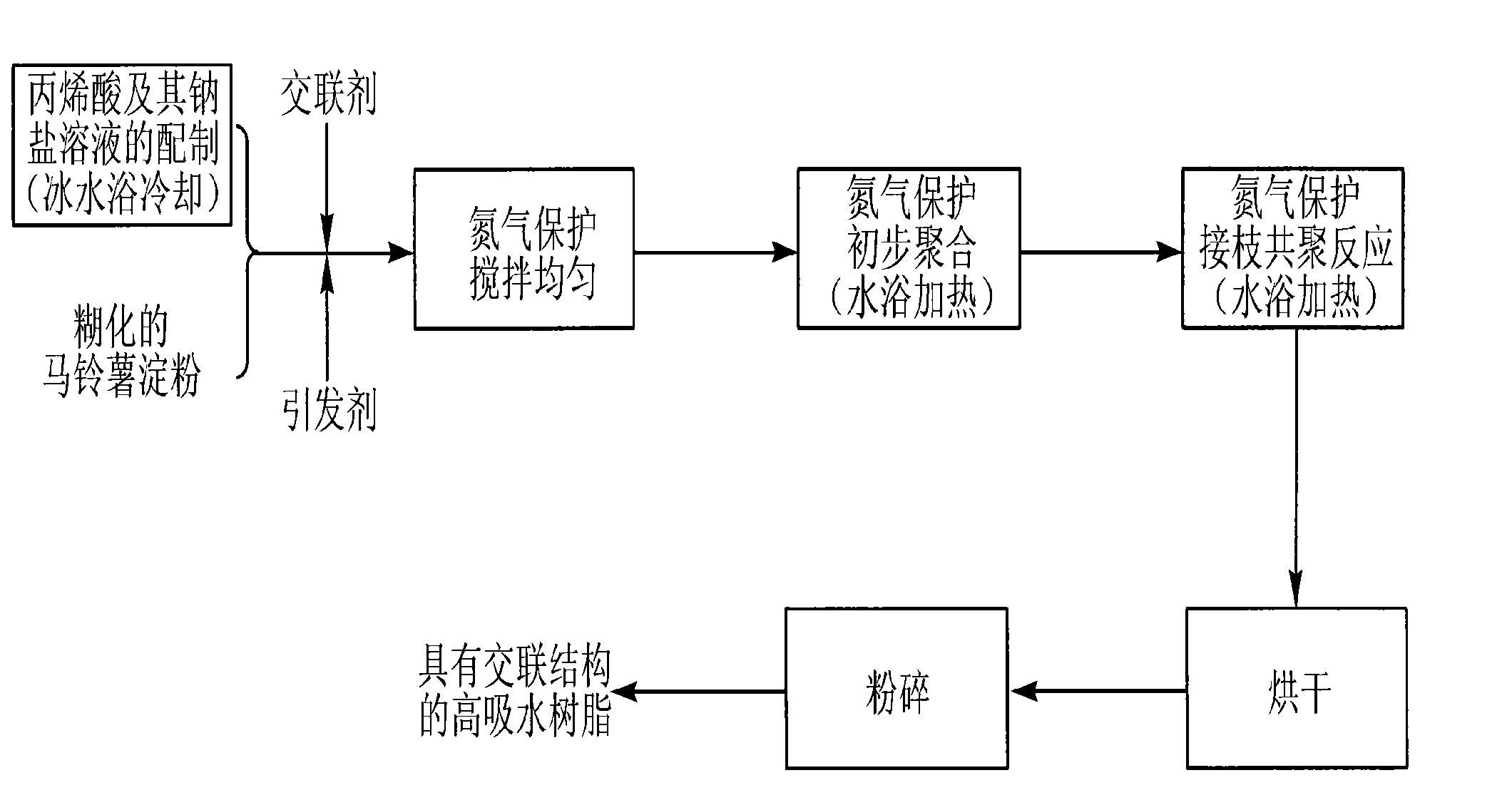

Method used

Image

Examples

Embodiment 1

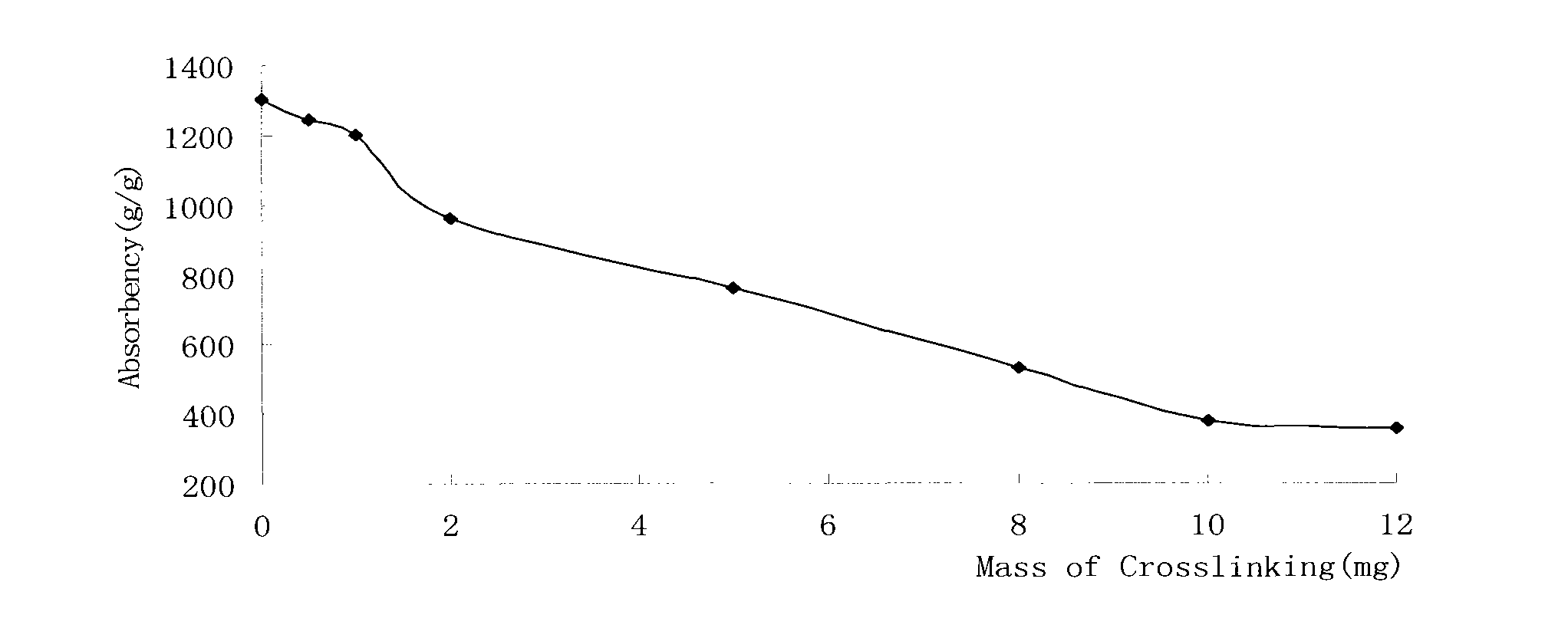

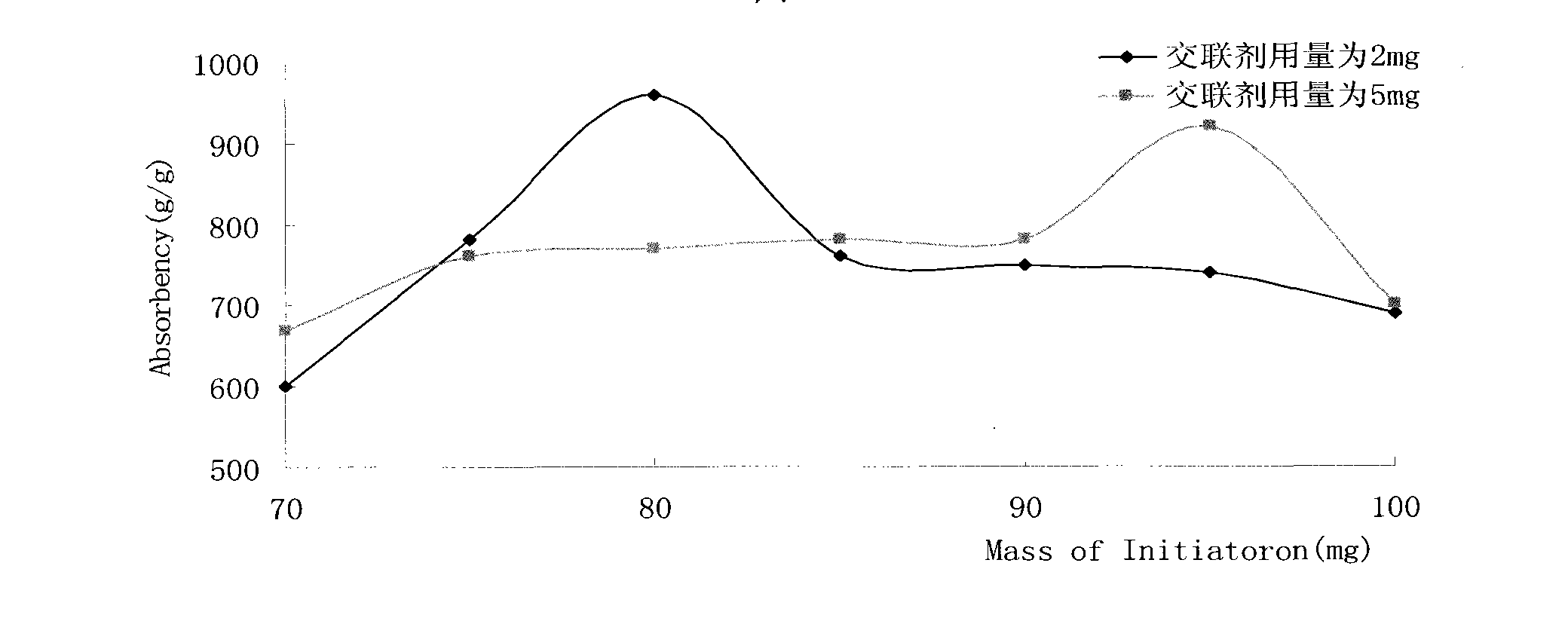

[0027]Embodiment 1: Weigh 7.5g sodium hydroxide, measure 22.5ml deionized water, be mixed with the sodium hydroxide solution that concentration is 25%, under the condition of ice-water bath cooling and stirring, neutralize 30.0g (28.6ml) Acrylic acid with inhibitor removed. Weigh 5.0g of potato starch, measure 25.0ml of deionized water, mix evenly under stirring, gelatinize under heating (65°C), then cool to room temperature, mix 80mg of potassium persulfate, 2mg of N,N'-methylenebispropene The amide, the prepared acrylic acid and its sodium salt solution, and the gelatinized potato starch were stirred for 0.5 h under the protection of nitrogen to make them evenly mixed. Heat with stirring, control the heating rate, and slowly increase the temperature of the water bath to fully proceed the reaction, and stop stirring when the temperature reaches 80°C. Thereafter, the temperature is gradually raised, and when the water boils, continue heating to keep it in a boiling water bath...

Embodiment 2

[0028] Embodiment 2: Weigh 10.0g sodium hydroxide, measure 30.0ml deionized water, be mixed with the sodium hydroxide solution that concentration is 25%, under the condition of ice-water bath cooling and stirring, neutralize 30.0g (28.6ml) Acrylic acid with inhibitor removed. Weigh 5.0g of potato starch, measure 25.0ml of deionized water, mix evenly under stirring, gelatinize under heating (65°C), then cool to room temperature, mix 80mg of potassium persulfate, 2mg of N,N'-methylenebispropene The amide, the prepared acrylic acid and its sodium salt solution, and the gelatinized potato starch were stirred for 0.5 h under the protection of nitrogen to make them evenly mixed. Heat with stirring, control the heating rate, and slowly increase the temperature of the water bath to fully proceed the reaction, and stop stirring when the temperature reaches 80°C. Thereafter, the temperature is gradually raised, and when the water boils, continue heating to keep it in a boiling water ba...

Embodiment 3

[0029] Embodiment 3: Weigh 7.5g sodium hydroxide, measure 22.5ml deionized water, be mixed with the sodium hydroxide solution that concentration is 25%, under the condition of ice-water bath cooling and stirring, neutralize 30.0g (28.6ml) Acrylic acid with inhibitor removed. Weigh 5.0g of potato starch, measure 25.0ml of deionized water, mix evenly under stirring, gelatinize under heating (65°C), then cool to room temperature, mix 95mg of potassium persulfate, 5mg of N,N'-methylenebispropene The amide, the prepared acrylic acid and its sodium salt solution, and the gelatinized potato starch were stirred for 0.5 h under the protection of nitrogen to make them evenly mixed. Heat with stirring, control the heating rate, and slowly increase the temperature of the water bath to fully proceed the reaction, and stop stirring when the temperature reaches 80°C. Thereafter, the temperature is gradually raised, and when the water boils, continue heating to keep it in a boiling water bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com