Method for preparing water-absorbing acrylic resin

An acrylic resin and water-absorbent technology, which is applied in the preparation of water-absorbent acrylic resin and the field of water-absorbent resin preparation, can solve the problems of high equipment requirements, high reaction temperature, and long drying time, and achieve good appearance, simple operation process, The effect of lowering the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

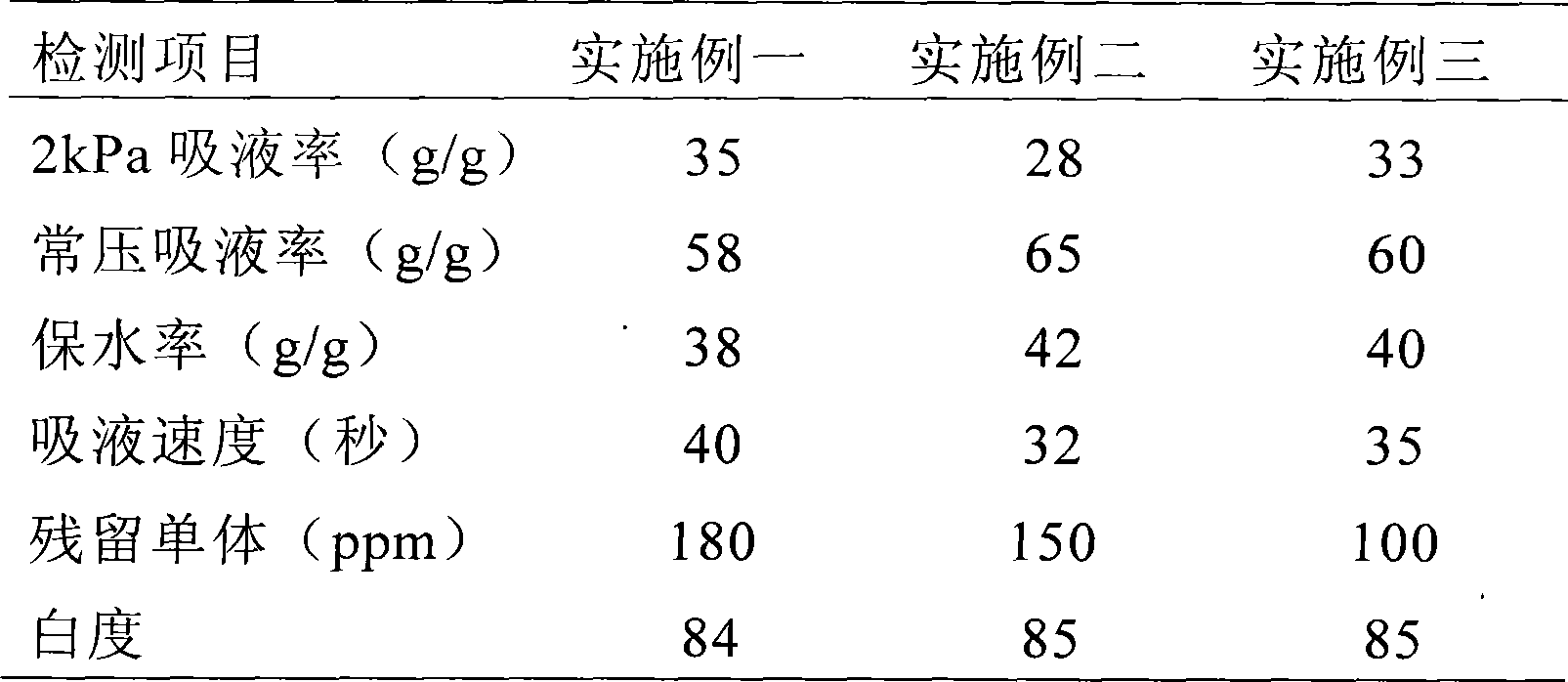

Examples

example 1

[0080] a) Add 500g of high-purity acrylic acid (in line with GBT17529.1-2008) and 180g of deionized water into a 2L kneader (Hangzhou Fuxiangtai Machinery Manufacturing Co., Ltd.), and then add 32wt% ionic membrane sodium hydroxide (Jiaxing Chemical Plant ) 650g, slowly added in the above-mentioned acrylic acid solution.

[0081] b) Add 2 g of sodium lauryl sulfate and 1 g of N, N'-methylenebisacrylamide into the above solution, and then pass nitrogen gas for 30 minutes, and the temperature of the aqueous monomer solution is 40° C. at this time.

[0082] c) adding a polymerization initiator, that is, 15 g each of a 10 wt % ammonium persulfate solution and a 10 wt % sodium bisulfite solution.

[0083] d) After reacting for 1 hour, the polymerized hydrogel was taken out.

[0084] e) Cut it into small particles with scissors, then put it into a meat grinder, add 10g fine powder of 100-150 mesh and 20g 10% sodium lauryl sulfate solution. Made into particles of about 6mm.

[008...

example 2

[0089] a) Add 500g of high-purity acrylic acid (according to GBT17529.1-2008) and 180g of deionized water into the kneader, and then slowly add 660g of 32wt% ionic membrane caustic soda into the above-mentioned acrylic acid solution.

[0090] b) 2 g of sodium lauryl sulfate and 1 g of N, N'-methylenebisacrylamide were added to the above solution, and then nitrogen gas was passed for 30 minutes. At this time, the temperature of the aqueous monomer solution was 40°C.

[0091] c) adding a polymerization initiator, that is, 15 g each of a 10 wt % ammonium persulfate solution and a 10 wt % sodium bisulfite solution.

[0092] d) After reacting for 1 hour, the polymerized hydrogel was taken out.

[0093] e) cut into small particles with scissors, then put into a meat grinder, add 10g of fine powder and 20g of 10wt% sodium lauryl sulfate solution. Made into particles of about 6mm.

[0094] f) The above granules are baked in an oven at 130°C for 2 hours to obtain dry granules with a...

example 3

[0098] a) Add 500g of high-purity acrylic acid (according to GBT17529.1-2008) and 180g of deionized water into the kneader, and then slowly add 650g of 32wt% ionic membrane caustic soda to the above-mentioned acrylic acid solution.

[0099] b) Add 2 g of sodium lauryl sulfate and 1 g of ethylene glycol dimethacrylate into the above solution, and then pass nitrogen gas for 30 minutes. At this time, the temperature of the aqueous monomer solution is 70°C

[0100] c) Adding a polymerization initiator, that is, 15 g of a 10 wt % ammonium persulfate solution.

[0101] d) After reacting for 1 hour, the polymerized hydrogel was taken out.

[0102] e) cut into small particles with scissors, then put into a meat grinder, add 10g of fine powder and 20g of 10wt% sodium lauryl sulfate solution. Made into particles of about 6mm.

[0103] f) The above granules are baked in an oven at 130°C for 2 hours to obtain dry granules with a water content of 5-7 wt%.

[0104] g) After the above pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com