Lithium ion battery composite negative electrode material, its preparation method, negative electrode with application of material thereof and lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unsatisfactory cycle stability, low yield of hydrothermal method, low capacity retention rate, etc., and achieve improved electrochemical performance. Performance, low cost, source-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of negative electrode material: Fe with a particle size of 100 nm 2 o 3 The powder is mixed with acetylene black with a particle size of 100 nm at a mass fraction of 3:7, and ball milled on a ball mill, the ball milling medium is acetone, and the ball milled product is dried to obtain Fe 2 o 3 / 70wt.% acetylene black composite powder material (wt.% refers to mass percentage, the same as in the following examples), to obtain the lithium ion battery negative electrode material. The particle size of the composite powder material is 50-200 nm, and its scanning electron microscope picture is as follows: figure 1 As shown, Fe can be seen in the figure 2 o 3 / Acetylene black has good combination and good dispersion, and the particle size is 50-200 nm.

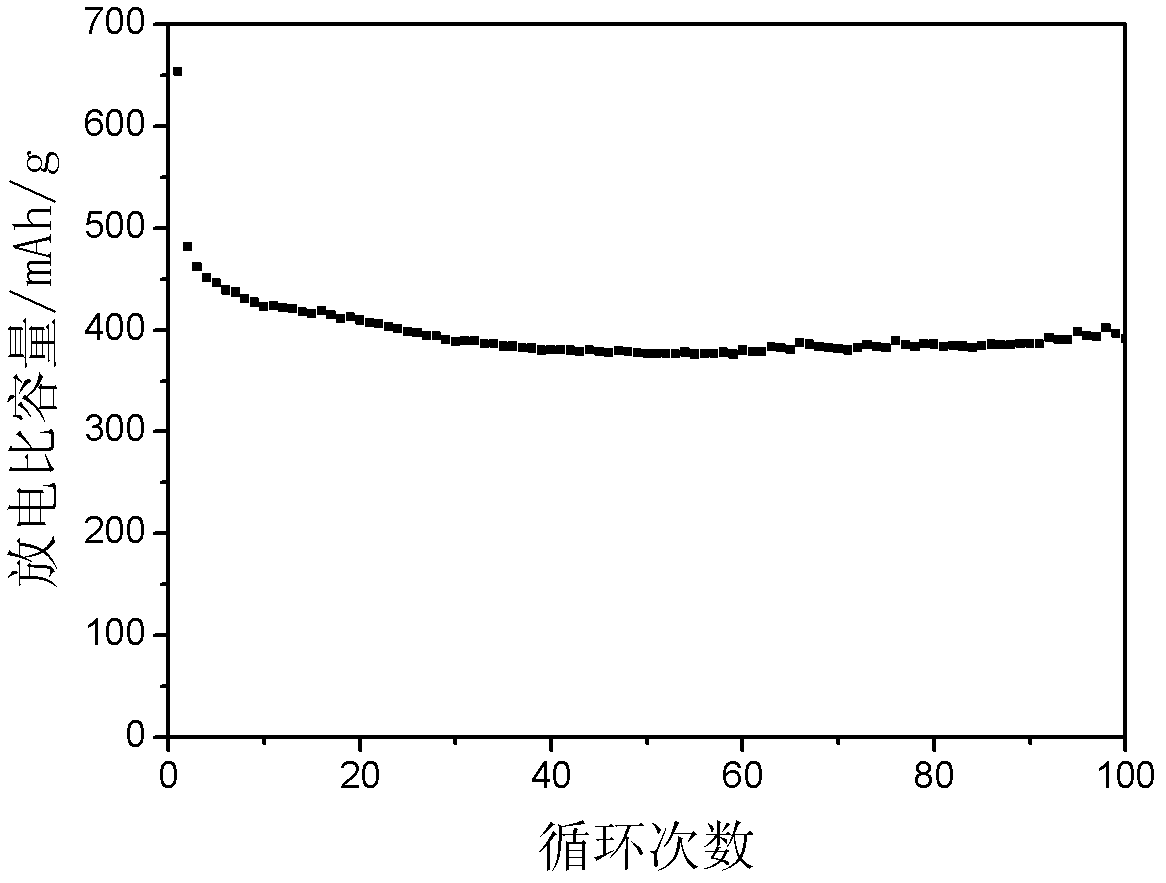

[0040] Preparation of the negative electrode: with N-methyl-pyrrolidone (NMP) as solvent, the prepared Fe 2 o 3 / 70wt.% acetylene black composite negative electrode material and binder polyvinylidene fluorid...

Embodiment 2

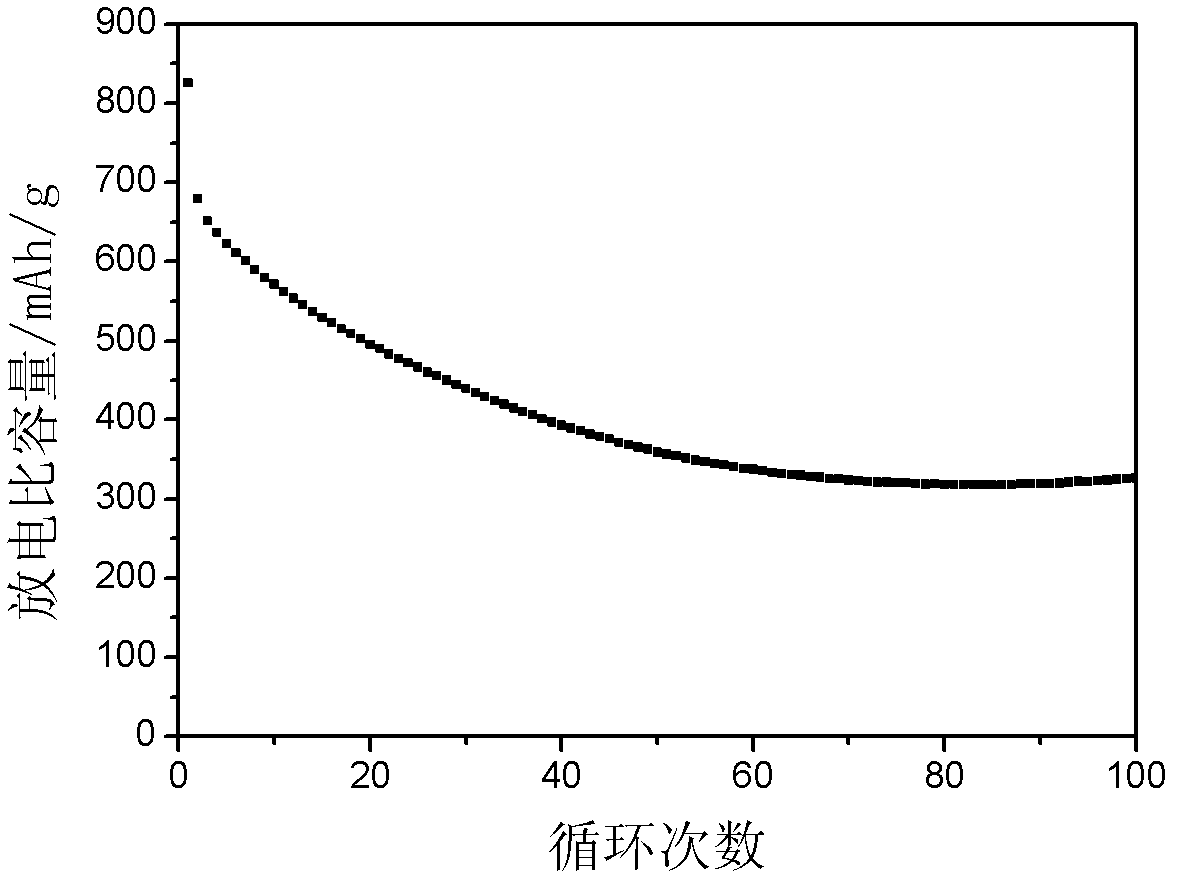

[0046] Preparation of negative electrode material: Mix Fe2O3 powder with a particle size of 10 nm and graphite with a particle size of 10 μm at a mass fraction of 7:3, and perform ball milling on a ball mill, the ball milling medium is water, and the ball milled product is baked Dry, get Fe 2 o 3 / 30wt.% graphite composite powder material, the particle size of the composite powder material is 50 nm-15 μm.

[0047] Preparation of the negative electrode: with N-methyl-pyrrolidone (NMP) as solvent, the prepared Fe 2 o 3 / 30wt.% graphite composite negative electrode material and binder polyvinylidene fluoride (PVDF) are uniformly mixed in a mass ratio of 8:1, coated on the current collector copper foil, and then dried to prepare the lithium ion battery negative electrode.

[0048] Preparation of the positive electrode: Using N-methyl-pyrrolidone (NMP) as the solvent, lithium cobaltate, PVDF and conductive agent acetylene black in a weight ratio of 8:1:1 were added to the solven...

Embodiment 3

[0052] Preparation of negative electrode material: 100 nm of Fe 2 o 3 and acetylene black of 50 nm are mixed on a ball mill with a mass fraction of 4:6, and ball milled on the ball mill, with acetone as the ball milling medium, and the ball milled product is dried to obtain Fe 2 o 3 / 60wt.% acetylene black composite powder material; then the material was calcined at 400°C for 6 hours in a nitrogen atmosphere to carry out carbothermal reduction reaction, and then the sample was cooled to room temperature and then taken out to obtain Fe 2 o 3 / Fe 3 o 4 / Acetylene black composite powder material, the content of acetylene black in the composite material is about 60wt.% (the error is 0~1wt.%), the X-ray diffraction pattern of the composite powder material is as follows Figure 4 As shown, the figure shows that the composite powder material contains Fe 2 o 3 and Fe 3 o 4 Two kinds of iron series oxides, the particle size of the composite powder material is 50-200 nm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com