Composite anode material of high-voltage lithium ion battery and lithium ion battery

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor high-temperature storage performance and low discharge capacity, and achieve high discharge capacity, high volume energy density, and excellent cycle. effect on performance and high temperature storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

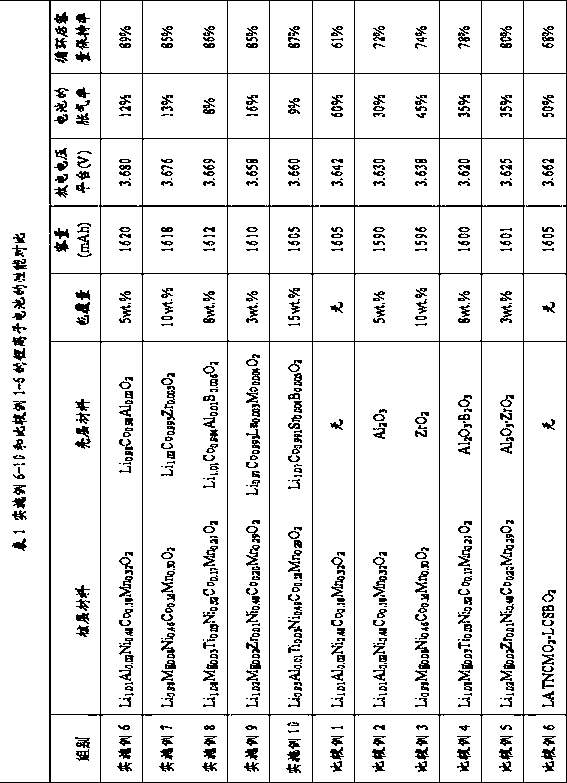

Examples

Embodiment 1

[0024] Embodiment 1: the positive electrode material that this embodiment provides is the Li that coating amount is 5wt% 1.01 Al 0.02 Ni 0.48 co 0.18 mn 0.32 o 2 / Li 0.98 co 0.98 Al 0.02 o 2 The composite cathode material, the BET of the composite cathode material is 0.42m 2 / g,D 50 = 10 μm. Among them, Li 1.01 Al 0.02 Ni 0.48 co 0.18 mn 0.32 o 2 / Li 0.98 co 0.98 Al 0.02 o 2 Expressed in Li 1.01 Al 0.02 Ni 0.48 co 0.18 mn 0.32 o 2 is the core layer material, Li 0.98 co 0.98 Al 0.02 o 2 It is the positive electrode material of the shell material, the same below. Its preparation method is as follows: Weigh a certain mass of lithium nitrate, cobalt nitrate, aluminum nitrate and citric acid and add them to 250 mL of ethanol, stir to dissolve them to form a lithium-cobalt-aluminum mixed solution, and adjust the pH of the solution to 6.8; add 250g Core layer material Li 1.01 Al 0.02 Ni 0.48 co 0.18 mn 0.32 o 2 (The core layer material is formed...

Embodiment 2

[0025] Embodiment 2: the positive electrode material that this embodiment provides is the Li that coating amount is 10wt% 0.98 Mg 0.08 Ni 0.46 co 0.16 mn 0.30 o 2 / Li 1.02 co 0.995 Zr 0.005 o 2 composite cathode material, the BET of the cathode material is 0.38m 2 / g,D 50 =15.0 μm. The preparation method is as follows: Weigh a certain mass of lithium acetate, cobalt acetate, zirconium acetate and ammonia water and add them to 500 mL of water, stir to dissolve them to form a lithium-cobalt-zirconium mixed solution, and adjust the pH of the solution to 8.9; add 250 g of the nuclear layer Material Li 0.98 Mg 0.08 Ni 0.46 co 0.16 mn 0.30 o 2 (The core layer material is formed by agglomeration of particles with a particle size of 1.5 μm, and the median particle size is D 50 =13 μm) powder, stirred evenly; after the above mixed solution was dried, it was first calcined at 650°C in an air atmosphere for 4 hours, and then at 1000°C in an air atmosphere for 4 hours to...

Embodiment 3

[0026] Embodiment 3: the positive electrode material that this embodiment provides is the Li that coating amount is 8wt% 1.08 Mg 0.03 Ti 0.03 Ni 0.52 co 0.17 mn 0.27 o 2 / Li 1.01 co 0.984 Al 0.01 B 0.006 o 2 composite cathode material, the BET of the cathode material is 0.21m 2 / g,D 50 =18.0 μm. The preparation method is as follows: Weigh a certain amount of lithium acetate, cobalt acetate, aluminum nitrate, boric acid and citric acid and add them to 250mL isopropanol, stir to dissolve them to form a mixed solution of lithium cobalt aluminum boron, and adjust the pH= 7; add 250g Li 1.08 Mg 0.03 Ti 0.03 Ni 0.52 co 0.17 mn 0.27 o 2 (The core layer material is formed by agglomeration of particles with a particle size of 2.5 μm, and the median particle size is D 50 = 16.5 μm) powder, and stirred evenly; after drying the above mixed solution, it was first calcined at 700°C in an air atmosphere for 5 hours, and then at 900°C in an air atmosphere for 15 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com