Patents

Literature

59results about How to "Meet the needs of thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite anode material of high-voltage lithium ion battery and lithium ion battery

ActiveCN102891307AIncrease volumetric energy densityMeet the needs of thinningCell electrodesCyclic processElectrical battery

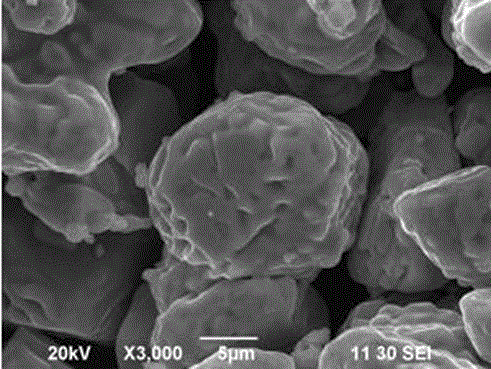

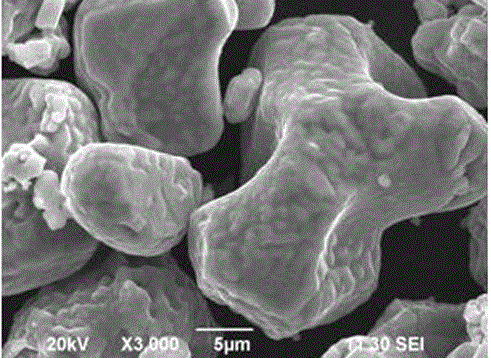

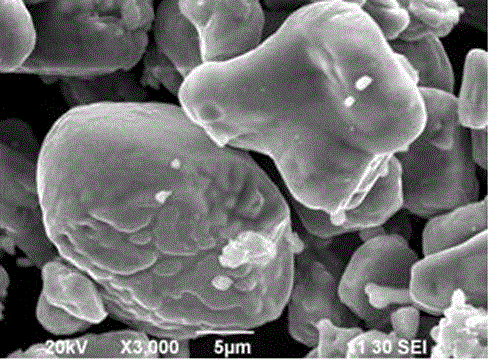

The invention discloses a composite anode material of a lithium ion battery. The composite anode material has a core-shell structure, a core layer material is Li1+nAwNi0.5+xCo0.2+yMn0.3+zO2, a shell layer material is Li1+aCo1-bMbO2, and the shell layer material accounts for 0.1-20% of the composite anode material in mass percent. Compared with the prior art, the composite anode material disclosed by the invention has the advantages that because a cladding layer can exert effective gram volume and discharge voltage platform under high voltage, the energy density of the battery is improved, and in addition, the structural stability of an enhancement matrix material of the cladding layer is good for effectively inhibiting the dissolution of Mn among the materials in a cyclic process, and the oxidation of electrolyte by the anode material is reduced; and in addition, the invention further discloses a preparation method of the anode material and the lithium ion battery containing the anode material.

Owner:DONGGUAN AMPEREX TECH +1

Anode material, preparation method of anode material and lithium ion battery comprising anode material

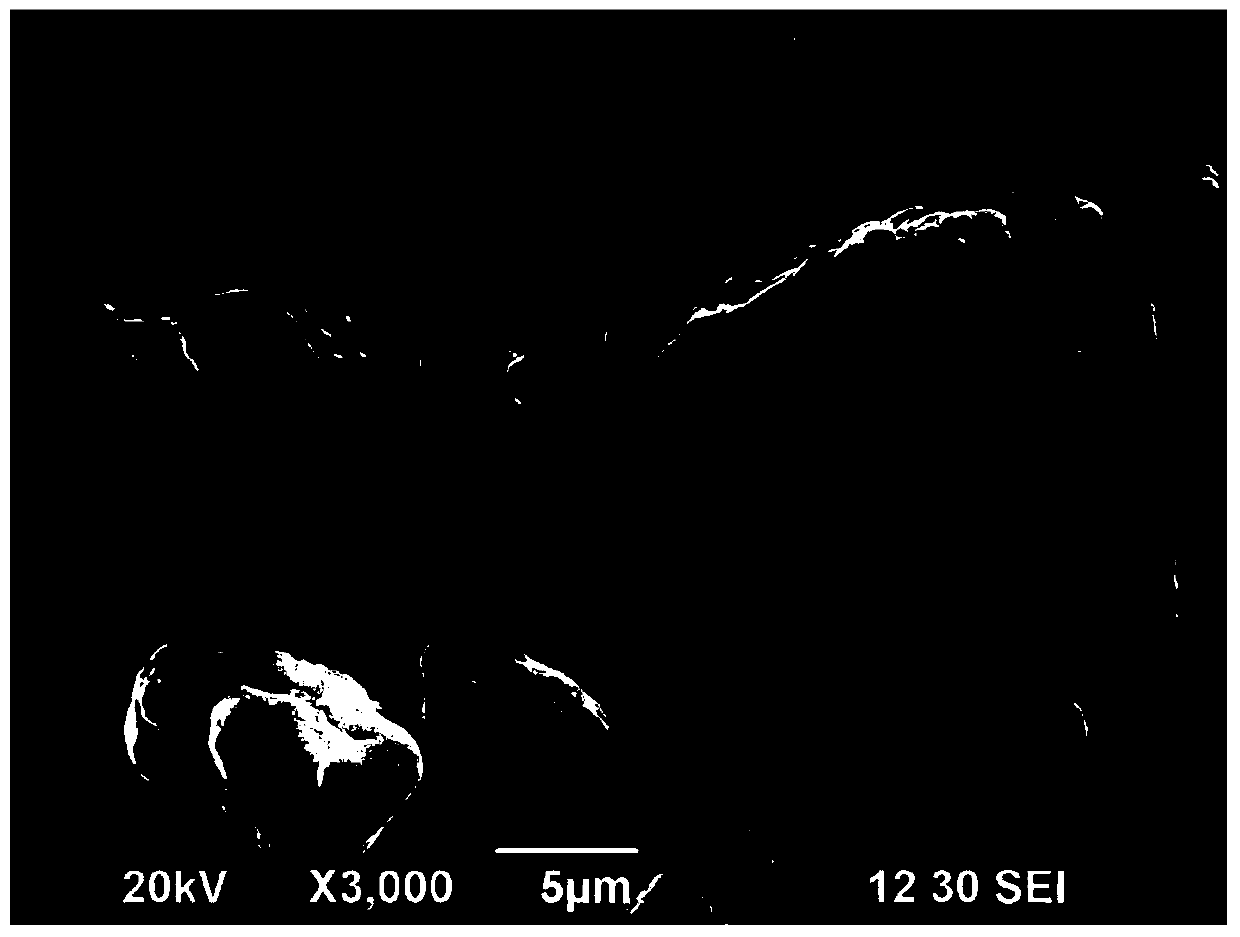

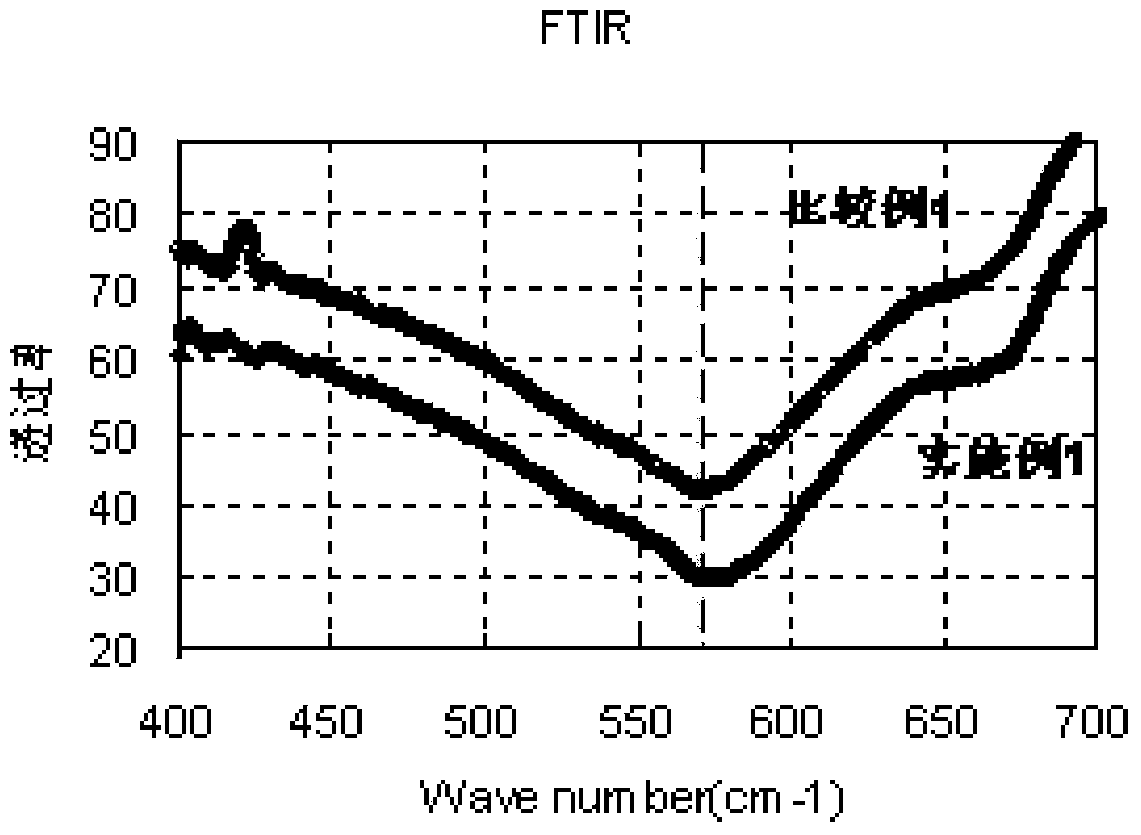

ActiveCN103137961AGood lithium ion conductivityEffective gram capacityElectrode thermal treatmentLi-accumulatorsGramLithium electrode

The invention belongs to the technical field of lithium ion batteries, and particularly relates to anode material. The anode material is formed by bulk phase material and surface material in a fusion mode, wherein the surface material is located on the surface of the bulk phase material, the bulk phase material is lithium cobalt oxide, the surface material is fusing granules which are composed of layered nickel lithium manganate, and the surface material accounts for 0.1-10% of the anode material by a mass percentage. Compared with the prior art, the anode material which is formed by the layered nickel lithium manganate is coated on the surface of the lithium cobalt oxide, due to the fact that the coating layer has good lithium-ion conduction performance, not only is a discharge voltage platform of the anode material not reduced and is the discharge voltage platform of the anode material increased on the contrary, but also the coating layer can play effective gram volume under high voltage, increase structural stability of base body material and accordingly improve the discharge capacity of the anode material under the high voltage and prolong the cycle life of the anode material significantly. In addition, the invention further discloses a preparation method of the anode material and a lithium ion battery comprising the anode material.

Owner:DONGGUAN AMPEREX TECH

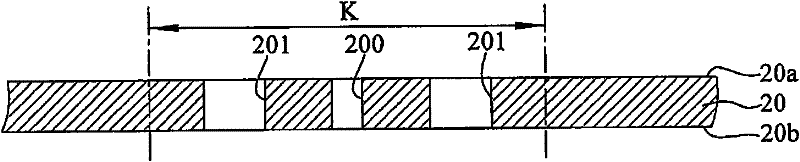

Pressure-sensitive adhesive for wafer grinding and preparation method thereof

InactiveCN103571367AImprove cohesionGood adhesionFilm/foil adhesivesPolyureas/polyurethane adhesivesPlastic materialsCohesive strength

The invention discloses a pressure-sensitive adhesive for wafer grinding and a preparation method thereof. The adhesive comprises a plastic base material, an adhesive layer coated on the base plastic material, and a release film which covers the adhesive layer. The preparation method of the pressure-sensitive adhesive comprises the following steps of: A) preparing a prepolymer; B) preparing an adhesive; C) preparing an adhesive tape. Compared with the prior art, the preparation method has the advantages that the dose and addition way of an initiating agent as well as the polymerizing temperature are controlled to realize the maximum molecular weight as well as high cohesive strength, and the problems of relatively high peeling strength and small shearing strength of the traditional pressure-sensitive adhesive are solved. In addition, a hard monomer added brings the pressure-sensitive adhesive with high shearing strength, and the demand on wafer grinding is met. The pressure-sensitive adhesive for wafer grinding is different from other adhesive tapes for wafer grinding in that a silane coupling agent bringing water resistance is directly polymerized onto a polymer molecular chain, instead of being directly added. Therefore, the migration of micromolecule in storage process is avoided, and the resulting influence to the effect or the resulting residue on a wafer is removed.

Owner:YANTAI DARBOND TECH

Lithium ion battery, anode material and preparation method of anode material

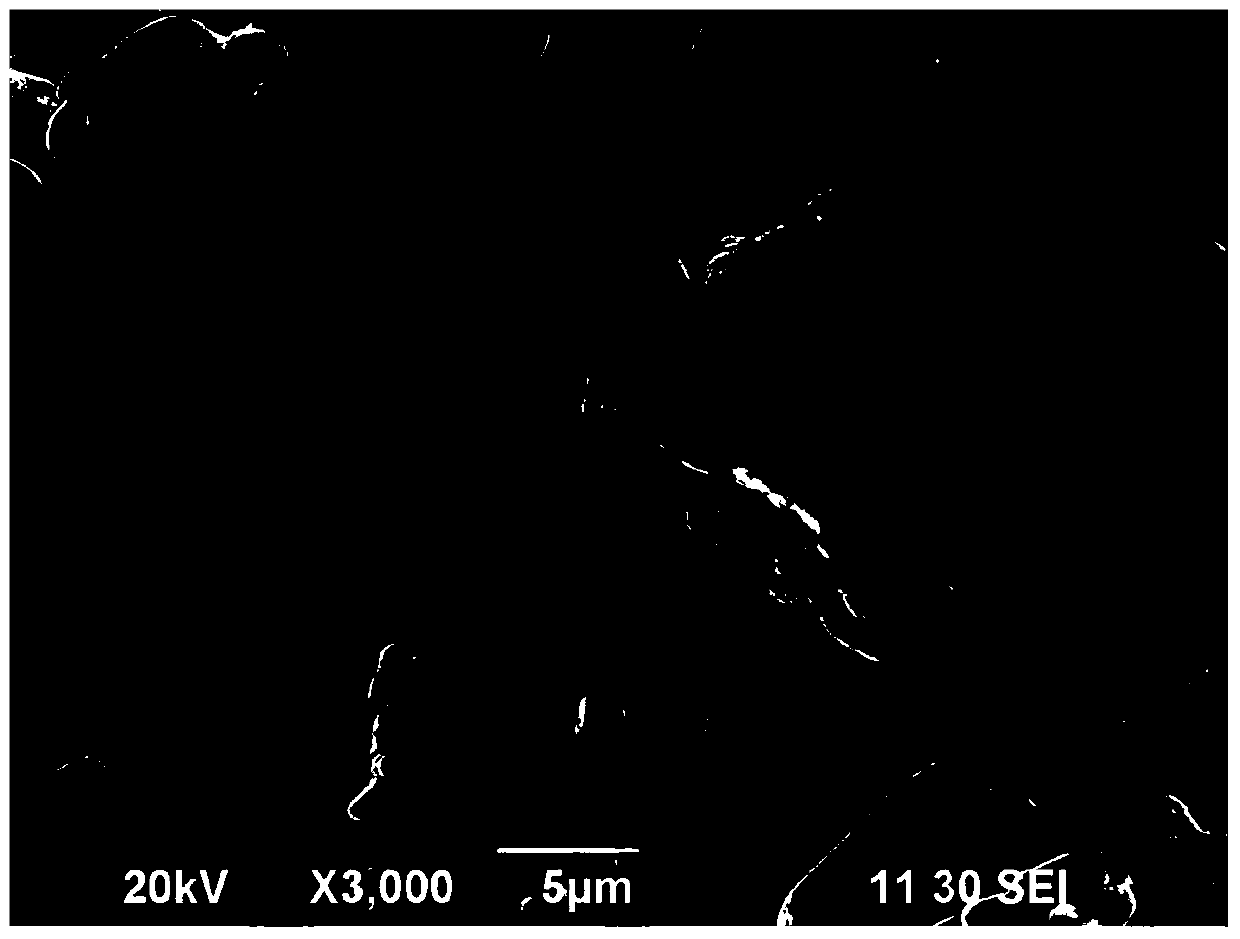

ActiveCN103474663AGood reversibilityIncrease energy densityCell electrodesManganateMaterials science

The invention discloses a lithium ion battery anode material and a preparation method of the lithium ion battery anode material, and also discloses a lithium ion battery using the anode material. The material comprises a melting structure formed by layered-layered-spinelle in an intergrowth manner, wherein layered lithium cobalt oxide is used as the inner layer; layered nickel lithium manganate is used as the middle layer; spinelle nickel lithium manganate is used as the outermost layer. The material is prepared in a way that a NiMn oxide is coated on the surface of a precursor Co3O4, and then is subjected to sintering with lithium salt in a mixing manner. Compared with the prior art, the lithium ion battery anode material in the intergrowth structure has higher discharge capacity and excellent cycle performance under high voltage.

Owner:DONGGUAN AMPEREX TECH

High-voltage anode material for lithium ion battery and lithium ion battery comprising same

ActiveCN103066282AImprove cycle performanceImprove securityCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a high-voltage anode material for a lithium ion battery. The anode material comprises a material A and a material B, wherein the material A has a core-shell structure, a core layer material is lithium cobalt oxide particles formed by primary particles, the median particle diameters D50 of the lithium cobalt oxide particles are 15-25 microns, and the structure formula of a core-shell material is LixNiyMnzPO4; the material B has a core-shell structure, the core layer material is the lithium cobalt oxide particles formed by secondary particles, and the median particle diameters D50 of the lithium cobalt oxide particles are is 3-9 microns; and the structure formula of the core-shell material is LiwAlpZrqO2, and the mass ratio of the material A to the material B is (0.1-10) to 1. Compared with the prior art, the high-voltage anode material for the lithium ion battery provided by the invention has the advantages that the large and small lithium cobalt oxide particles are combined reasonably, different core layer materials can be arranged on the surfaces of the lithium cobalt oxide particles, and the secondary particles are selected as the small lithium cobalt oxide particles, so that the cycle performance and the safety performance of the anode material under high voltage are notably improved.

Owner:DONGGUAN AMPEREX TECH

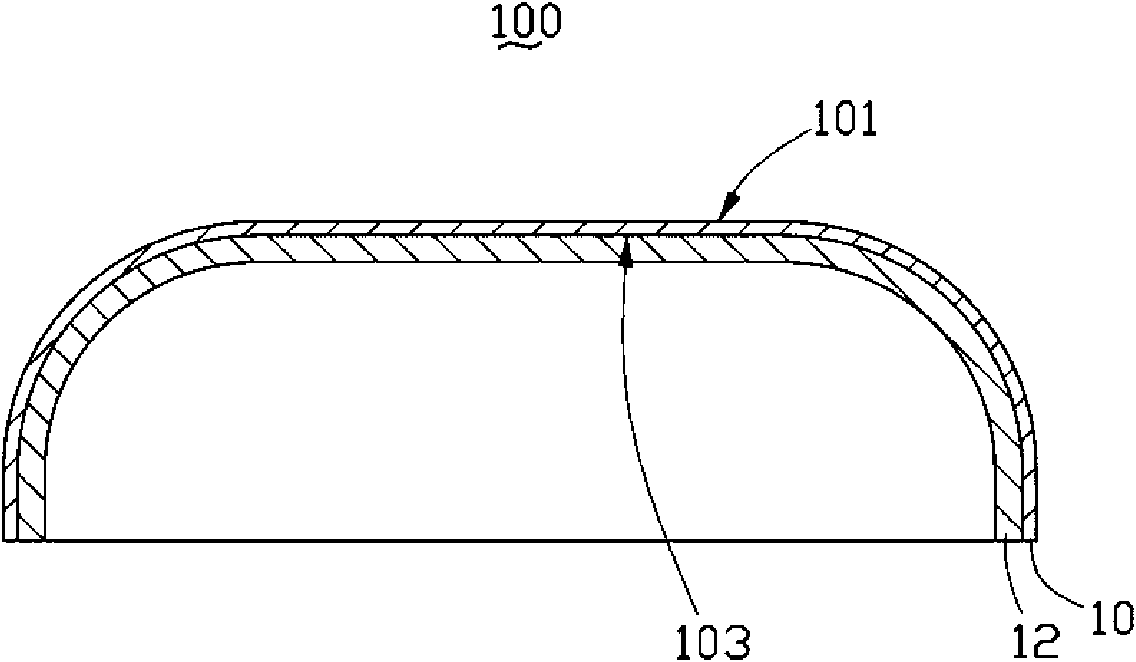

Portable electronic device shell

InactiveCN101610647ASimple manufacturing methodReduce processSynthetic resin layered productsTelephone set constructionsEngineeringPlastic film

The invention relates to a portable electronic device shell made by forming a plastic film layer in a thermal pressing forming mode. The portable electronic device shell has small thickness and satisfies the requirement of thin products, and the manufacture method thereof is simple and practical and has few working procedures and low cost.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

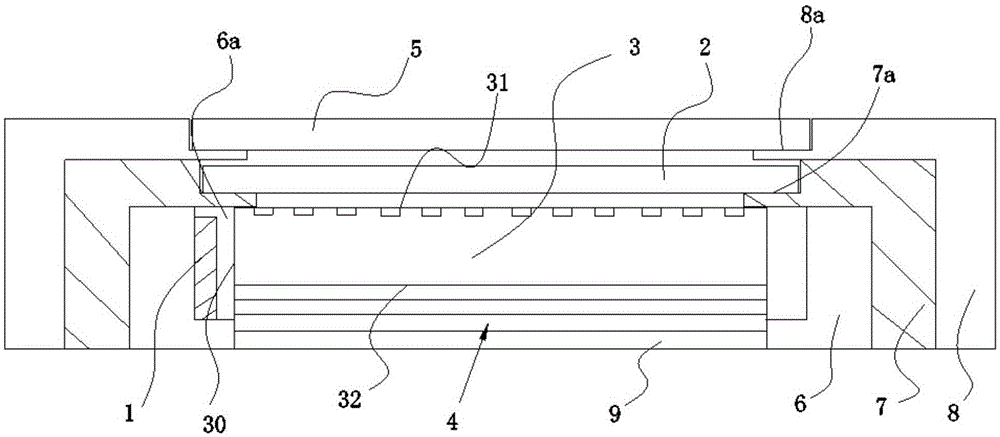

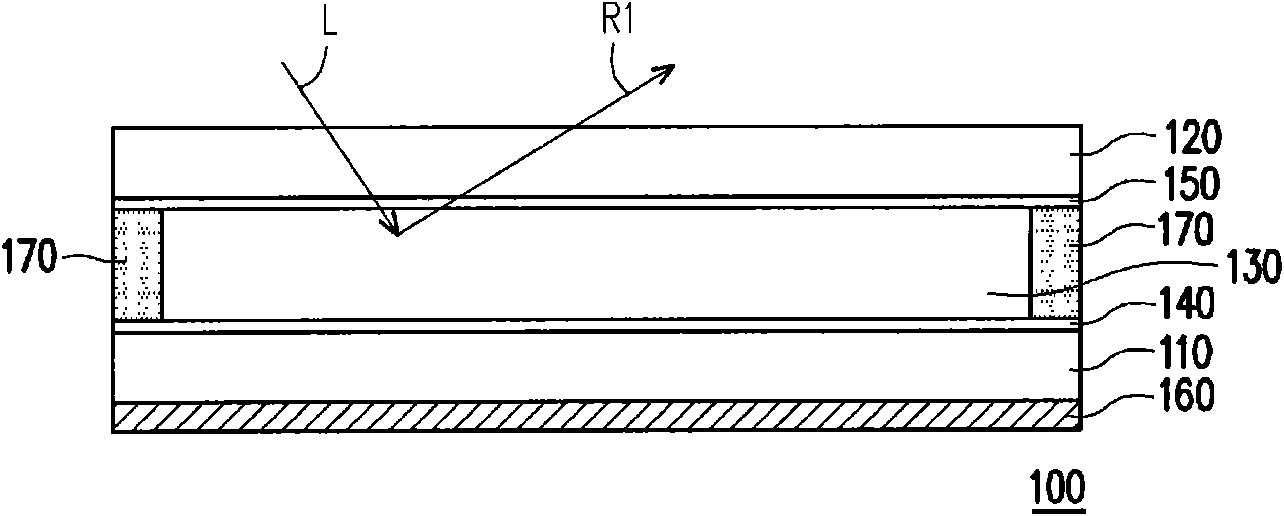

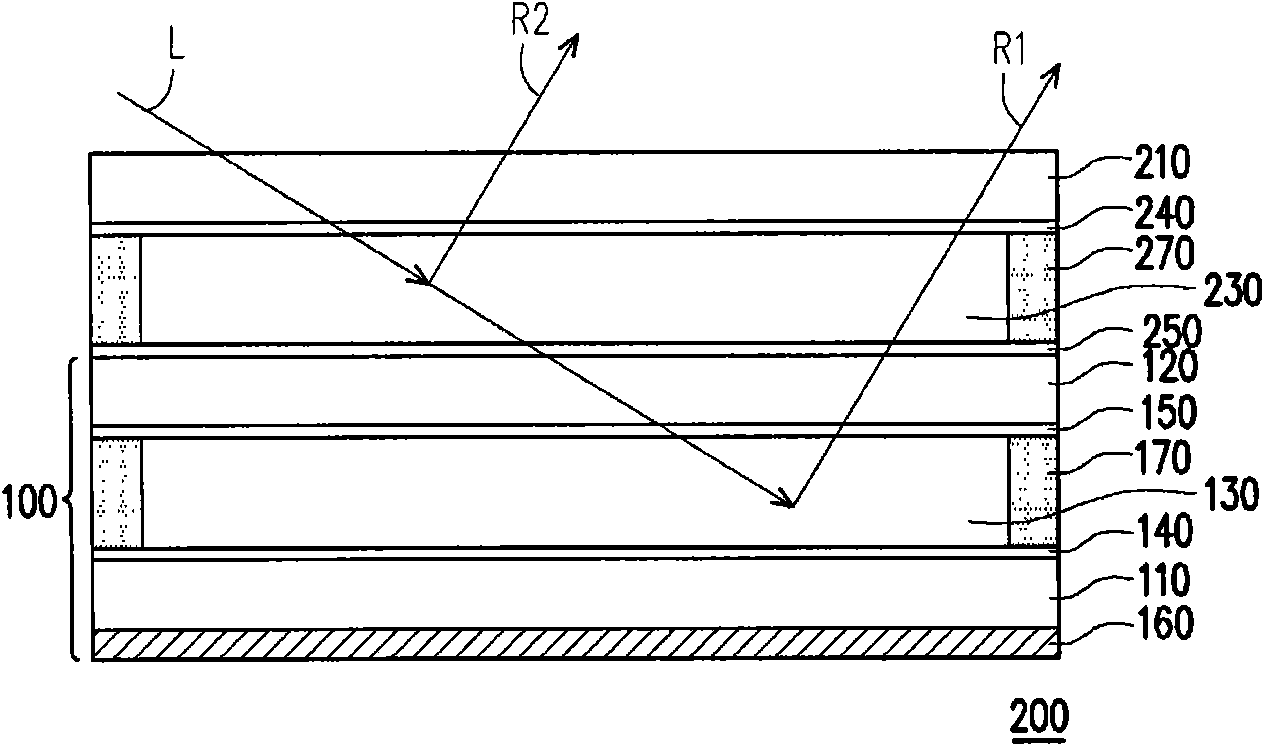

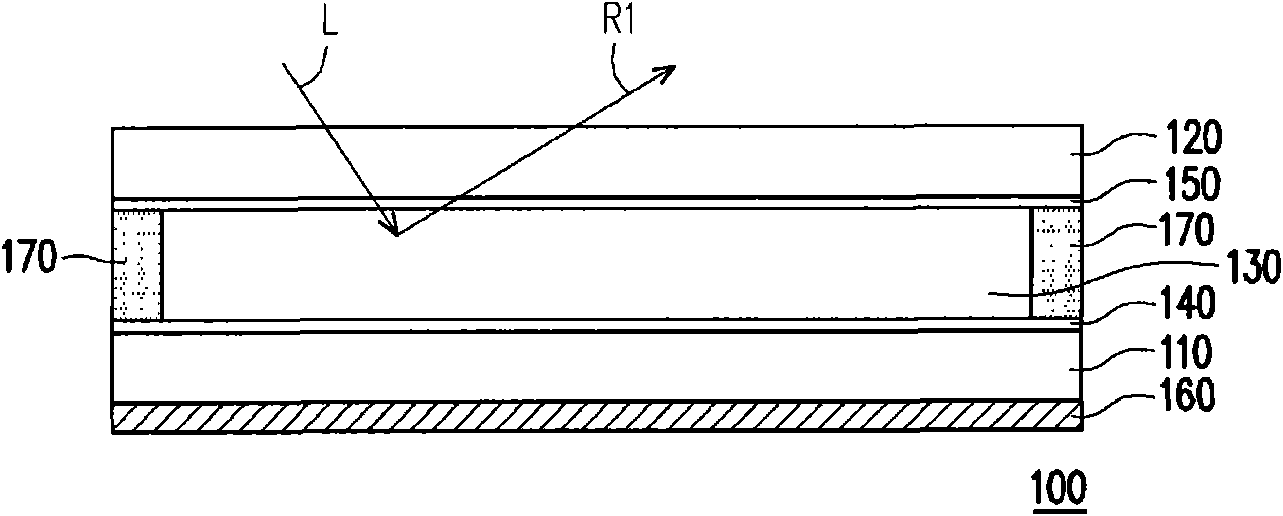

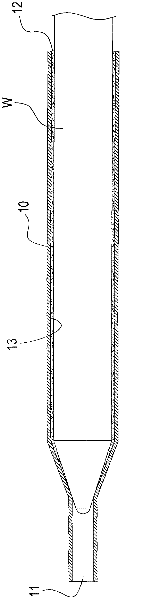

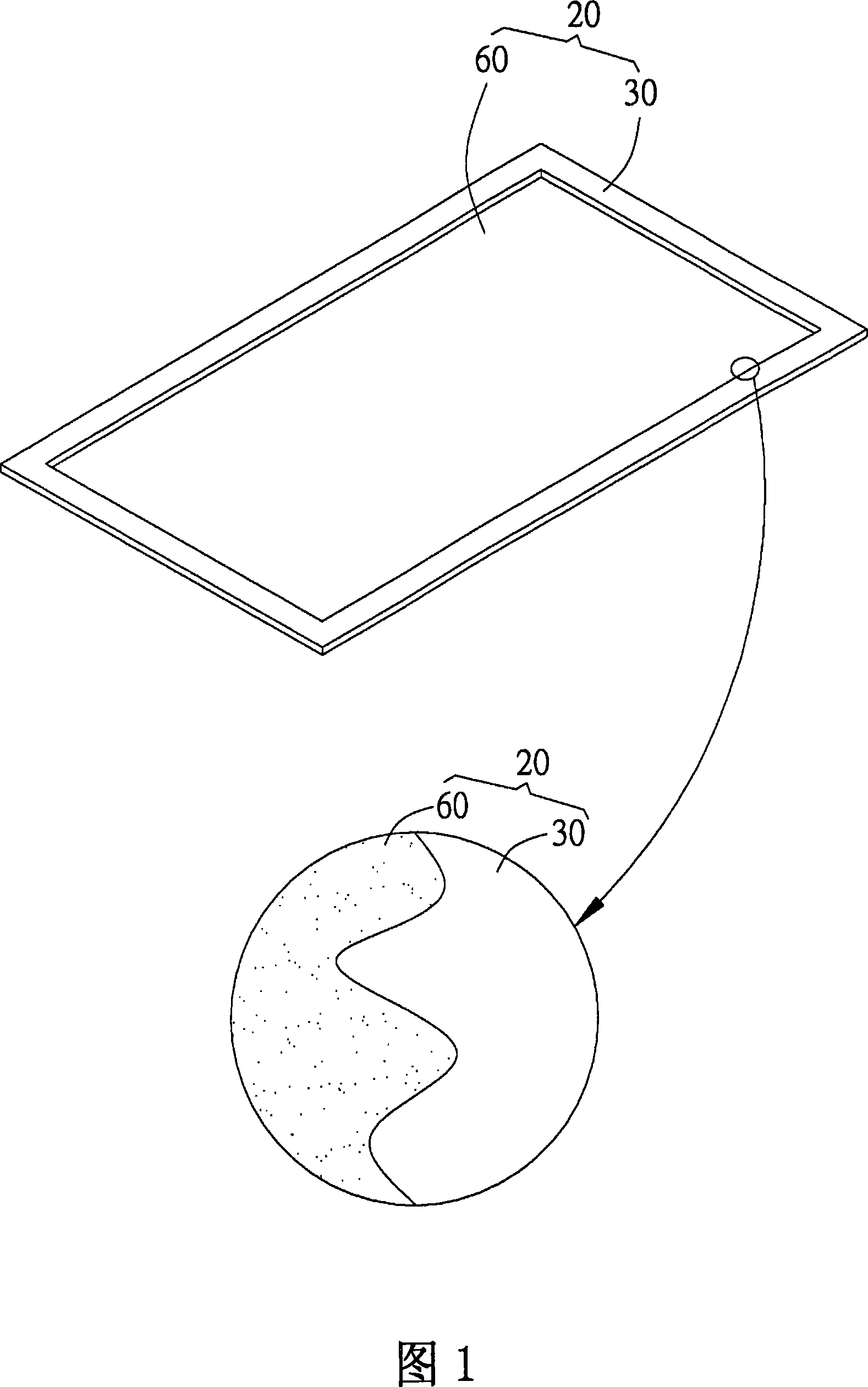

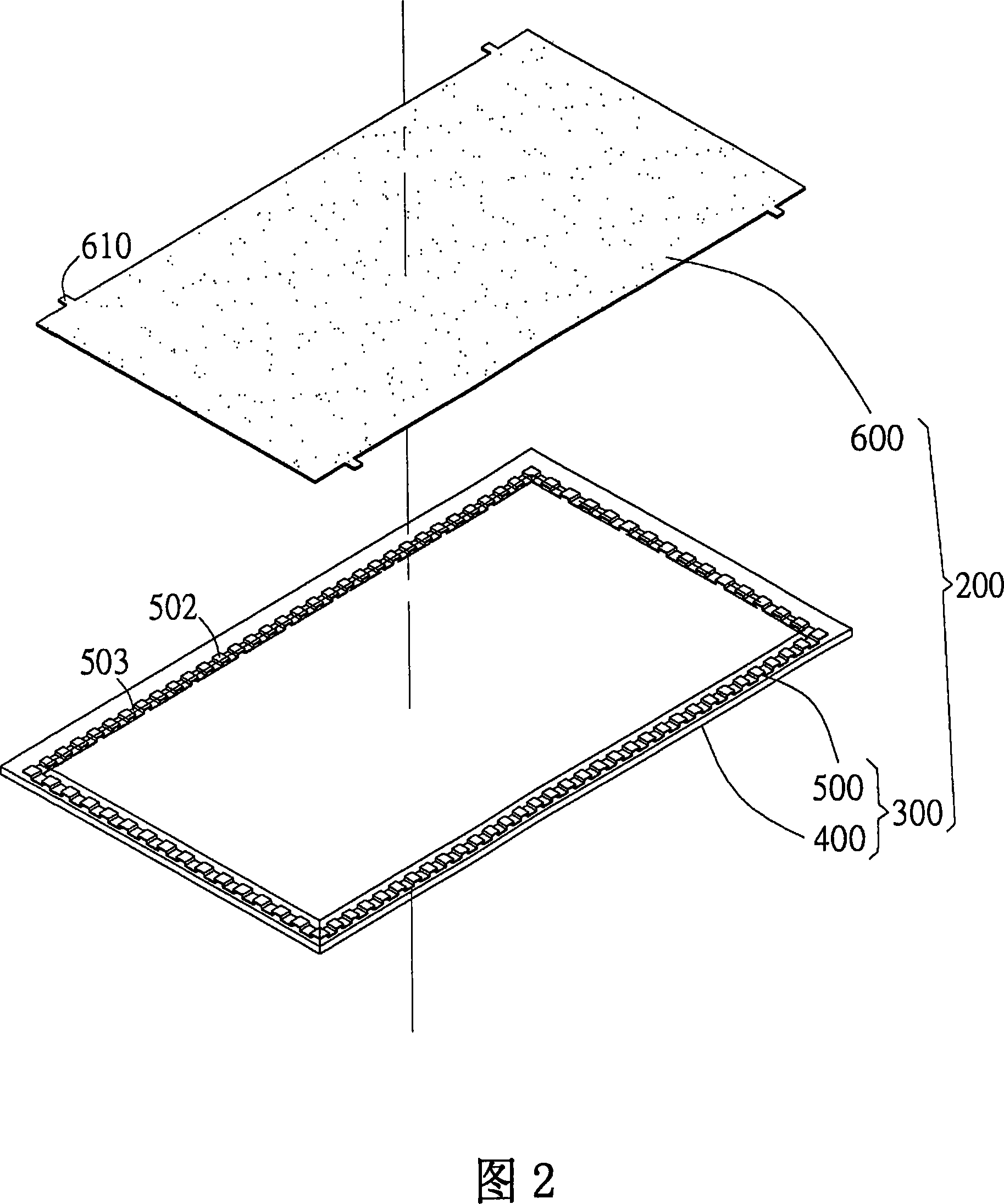

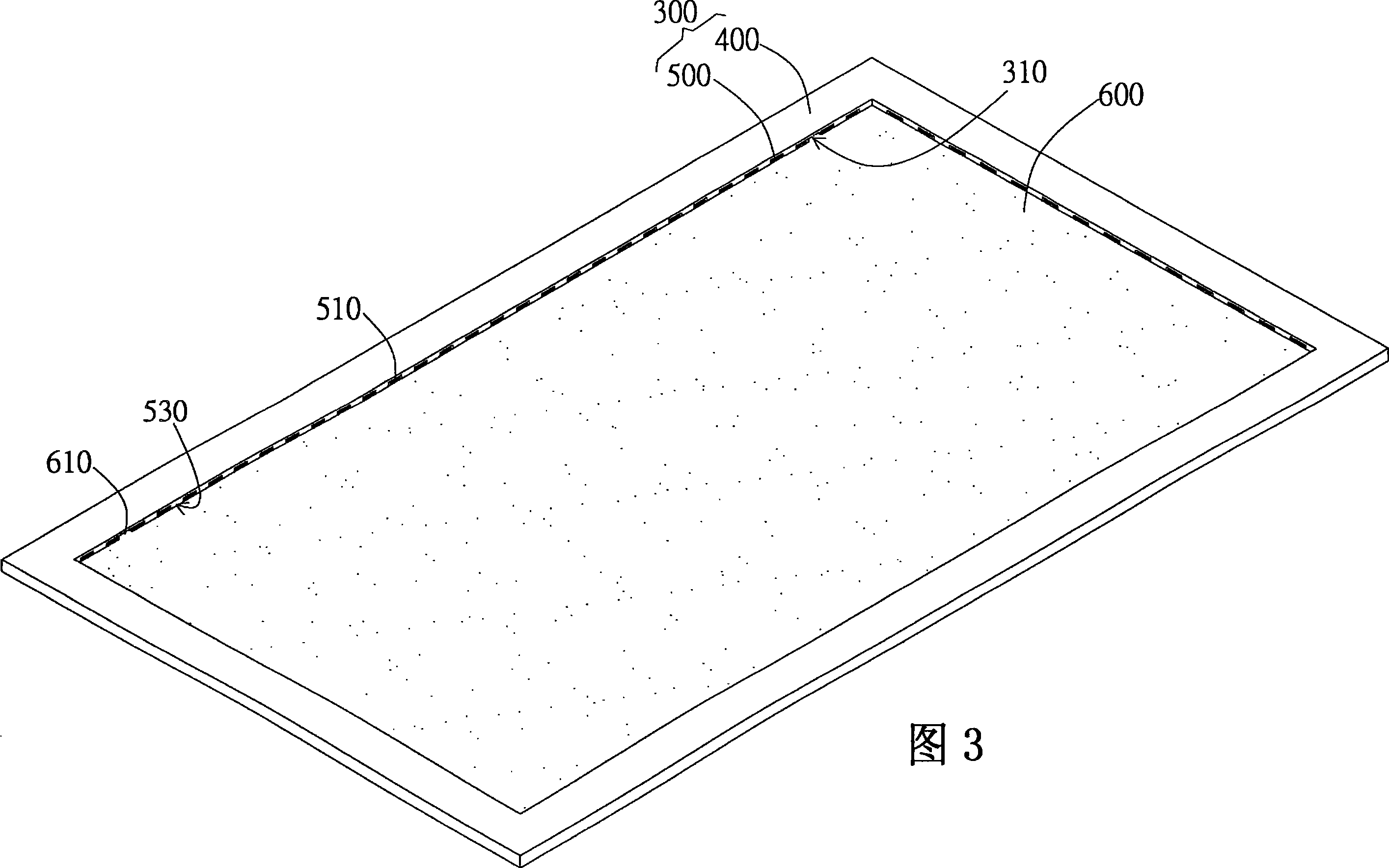

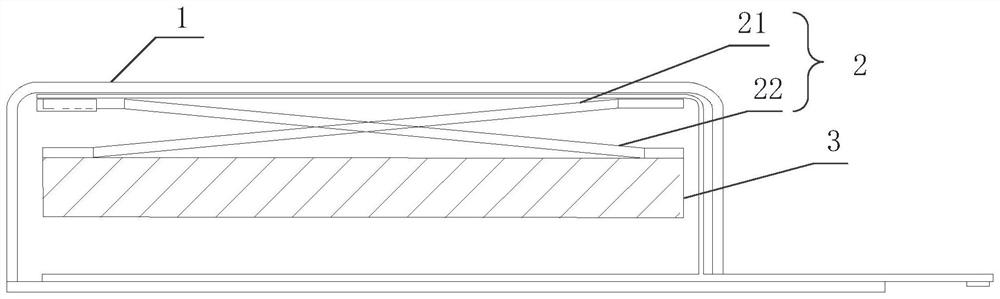

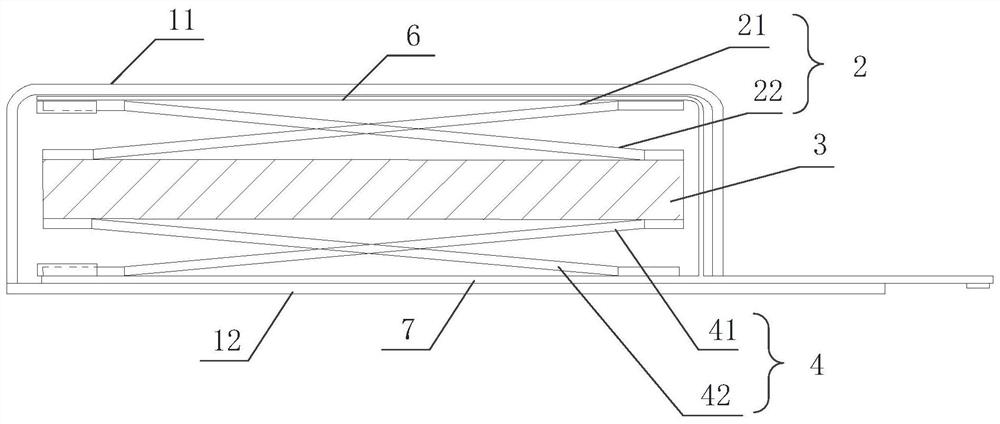

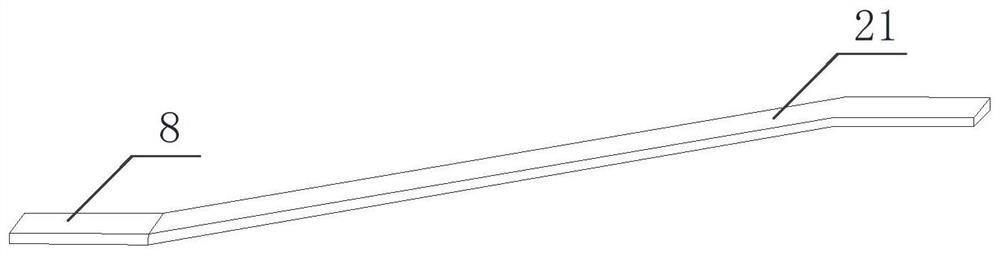

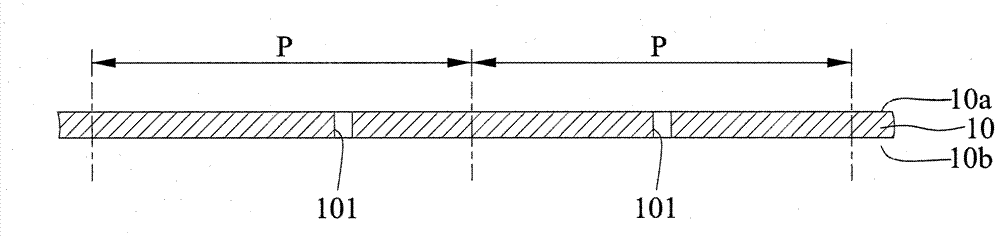

Backlight module and display device

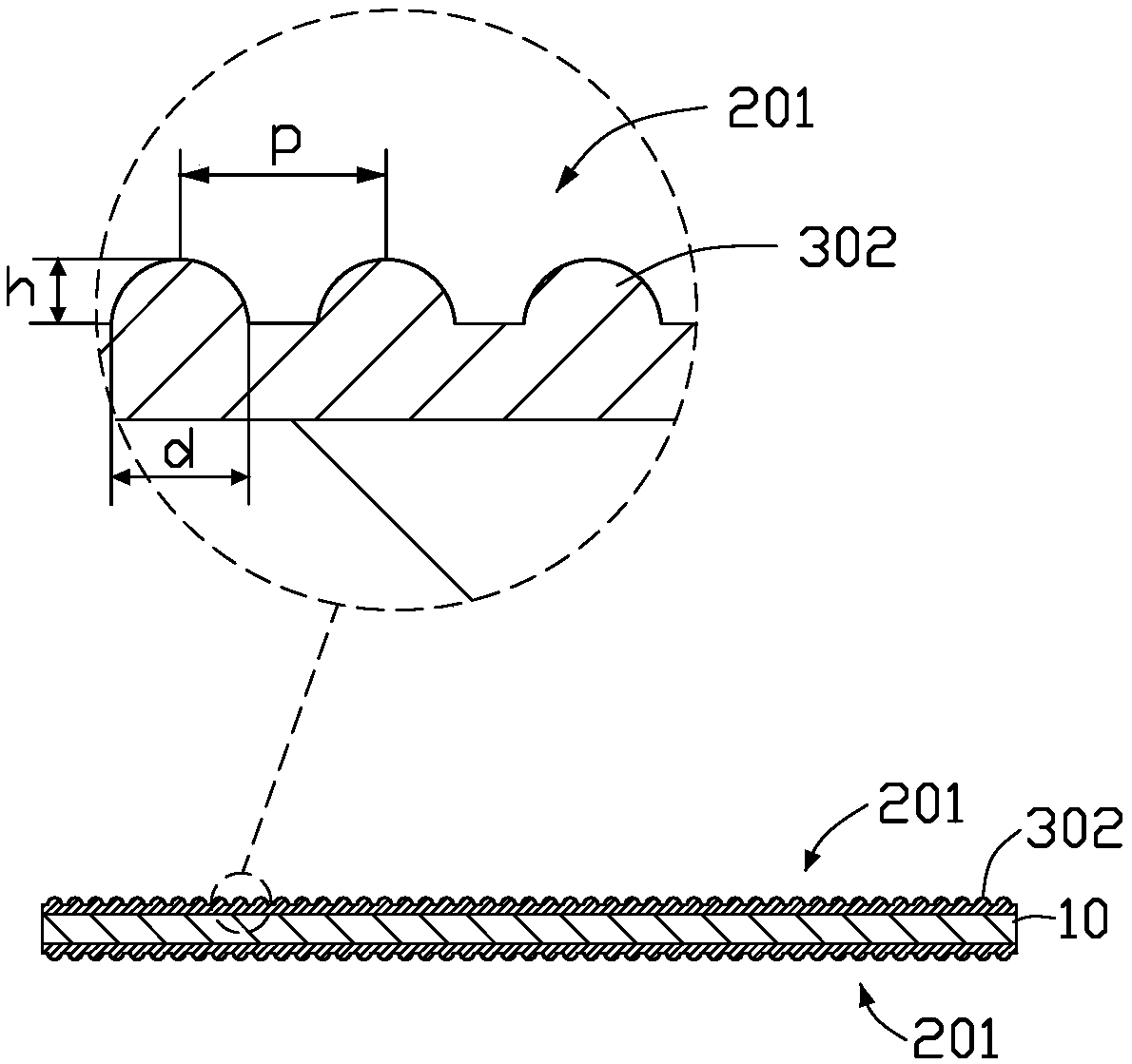

InactiveCN105334665AImprove light extraction efficiencyImprove reliabilityOptical light guidesNon-linear opticsDielectricLight guide

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

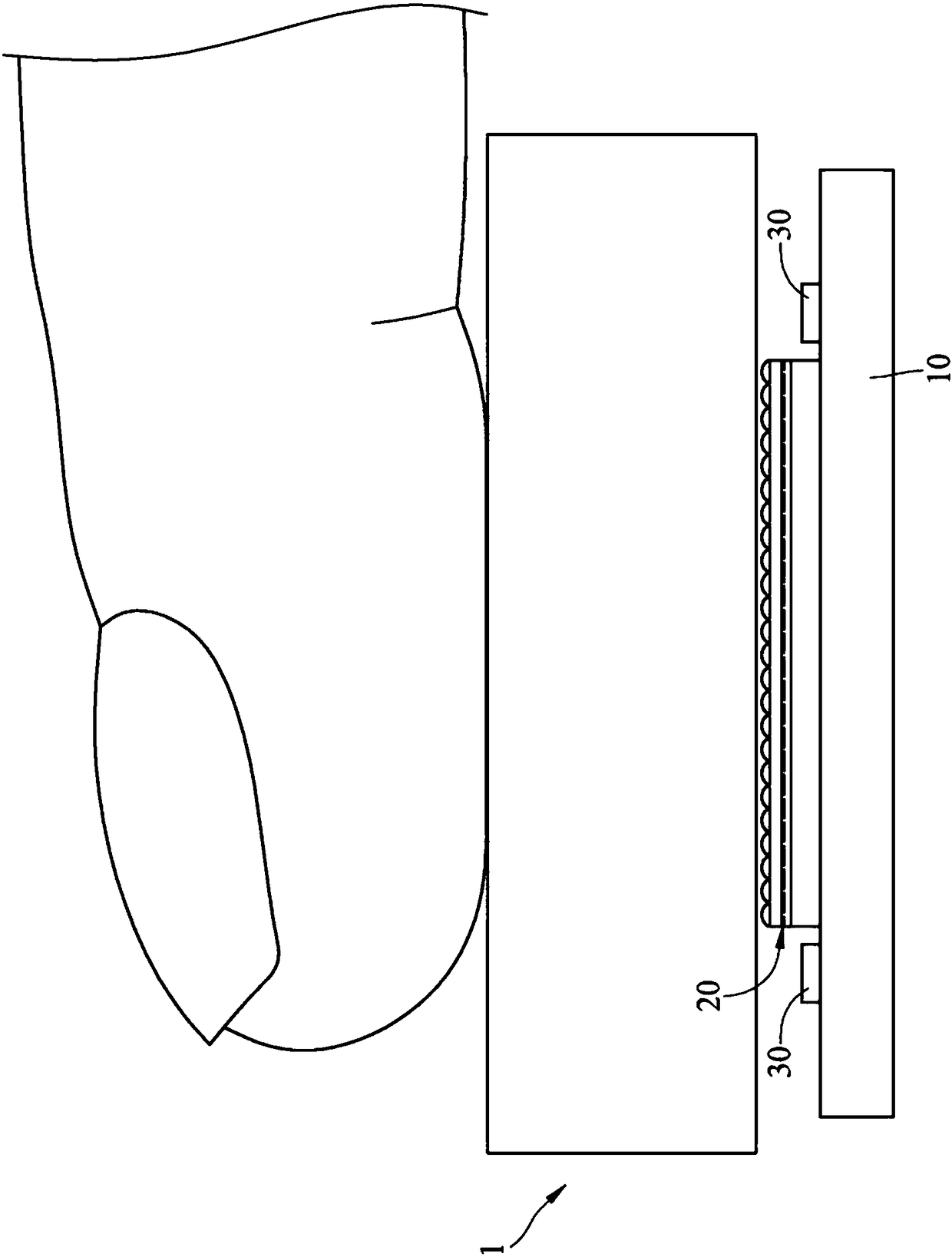

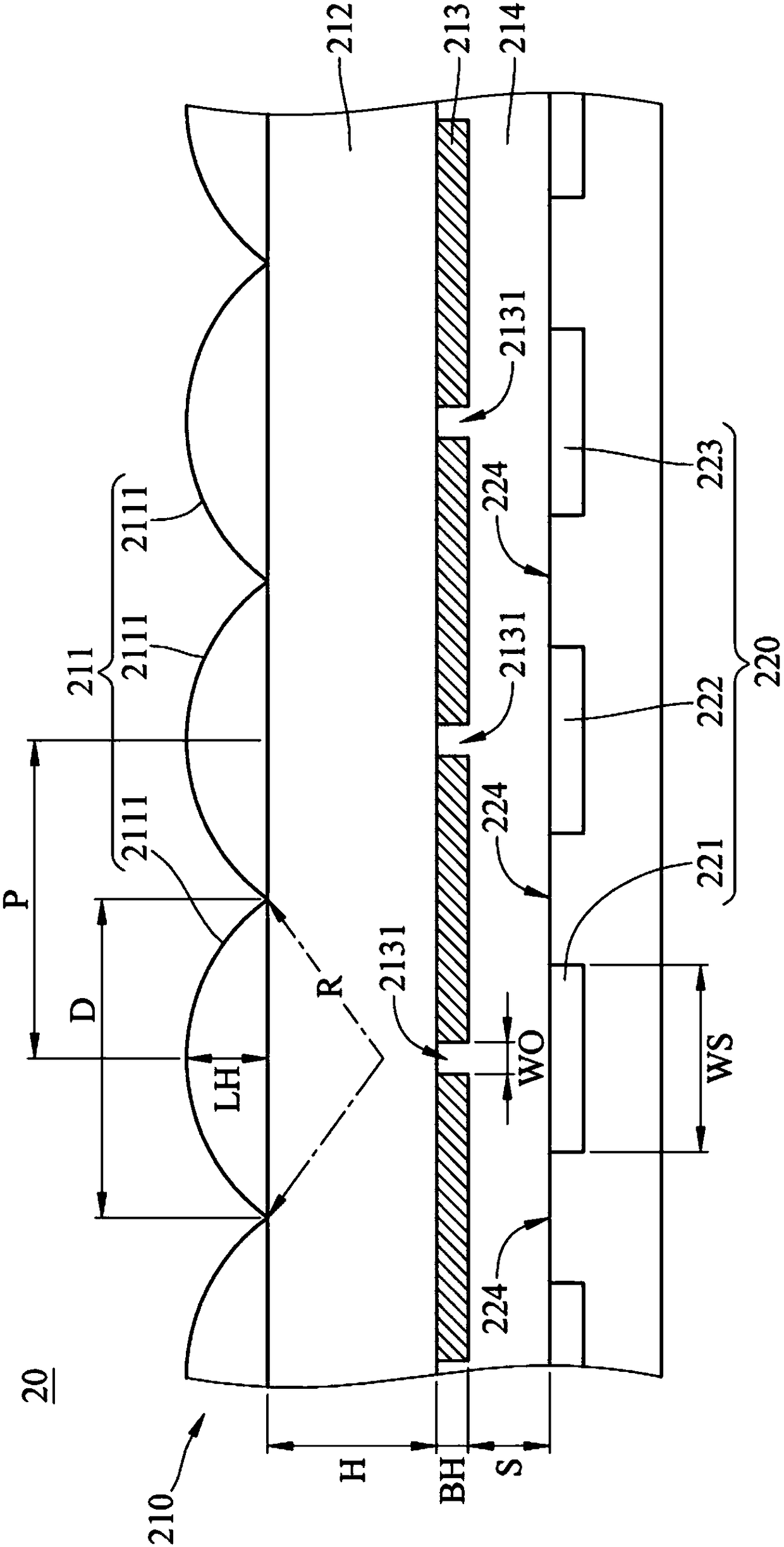

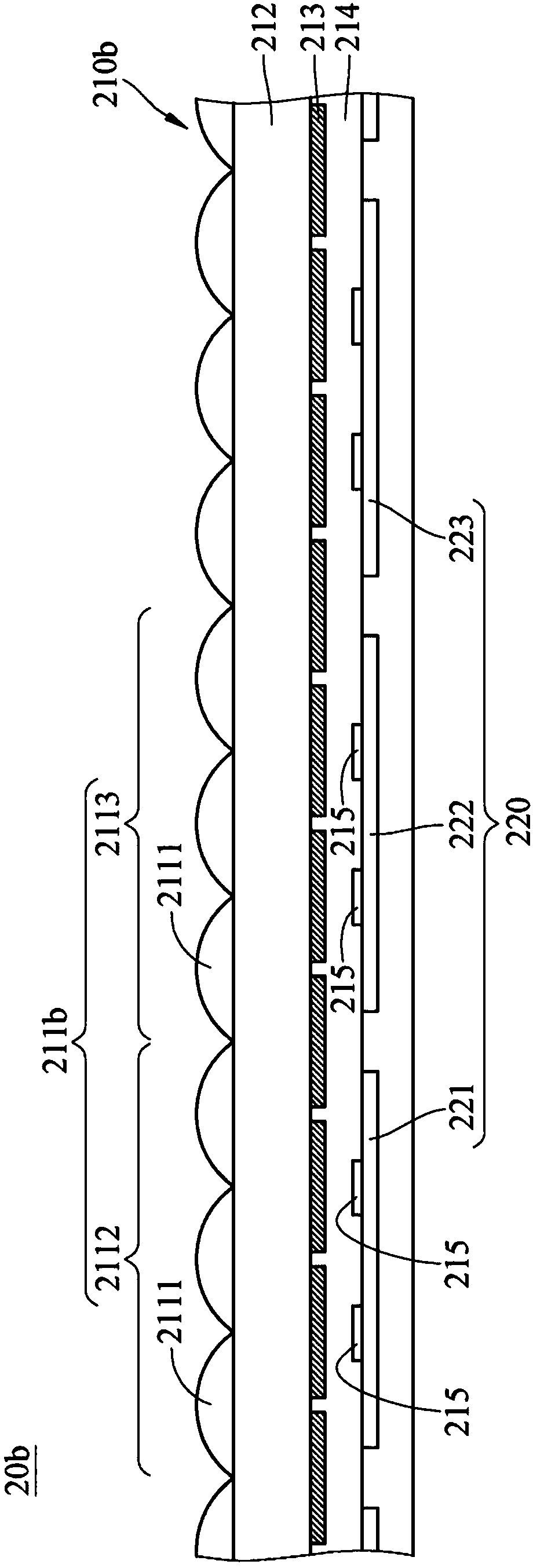

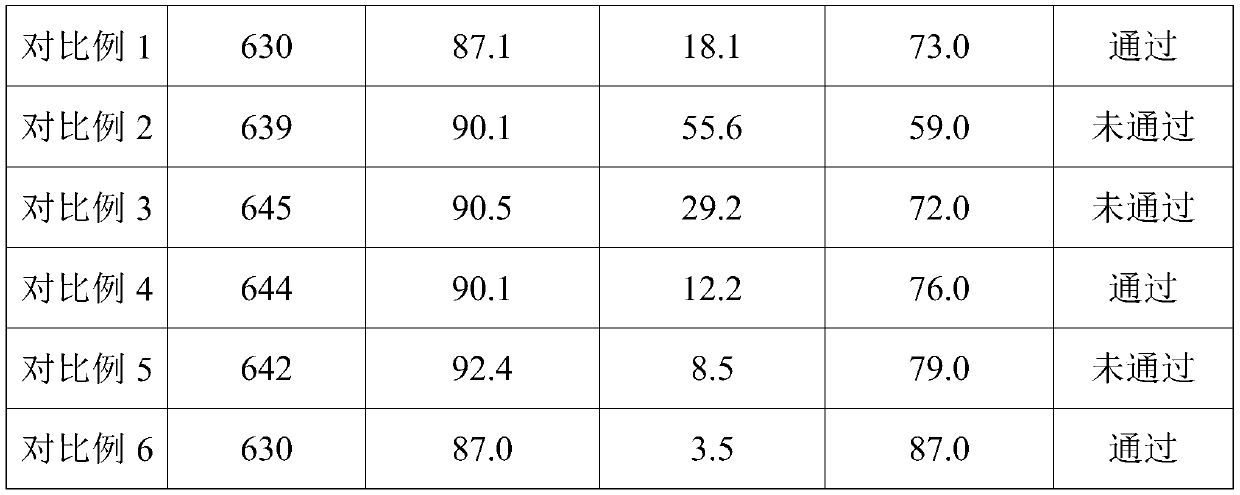

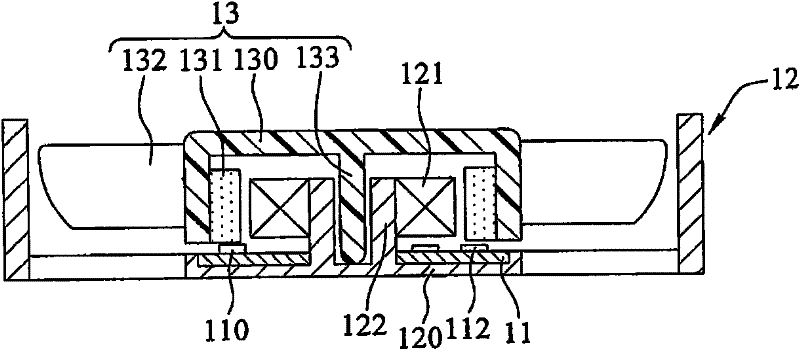

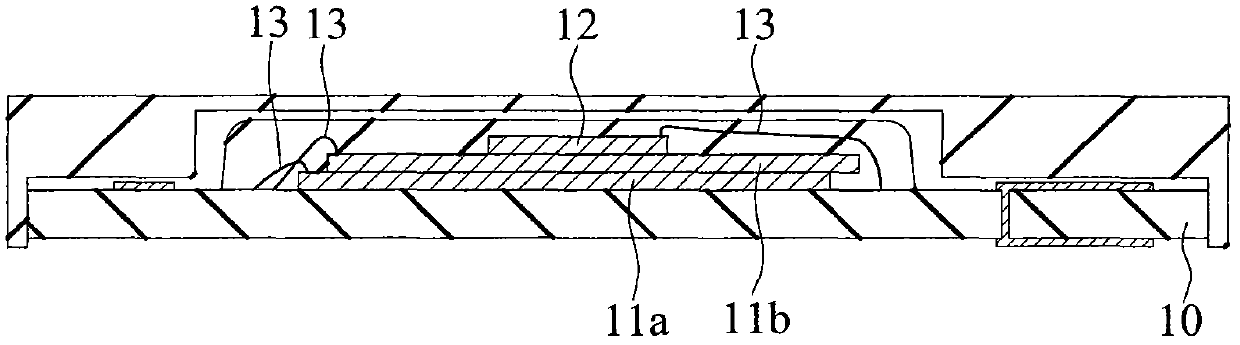

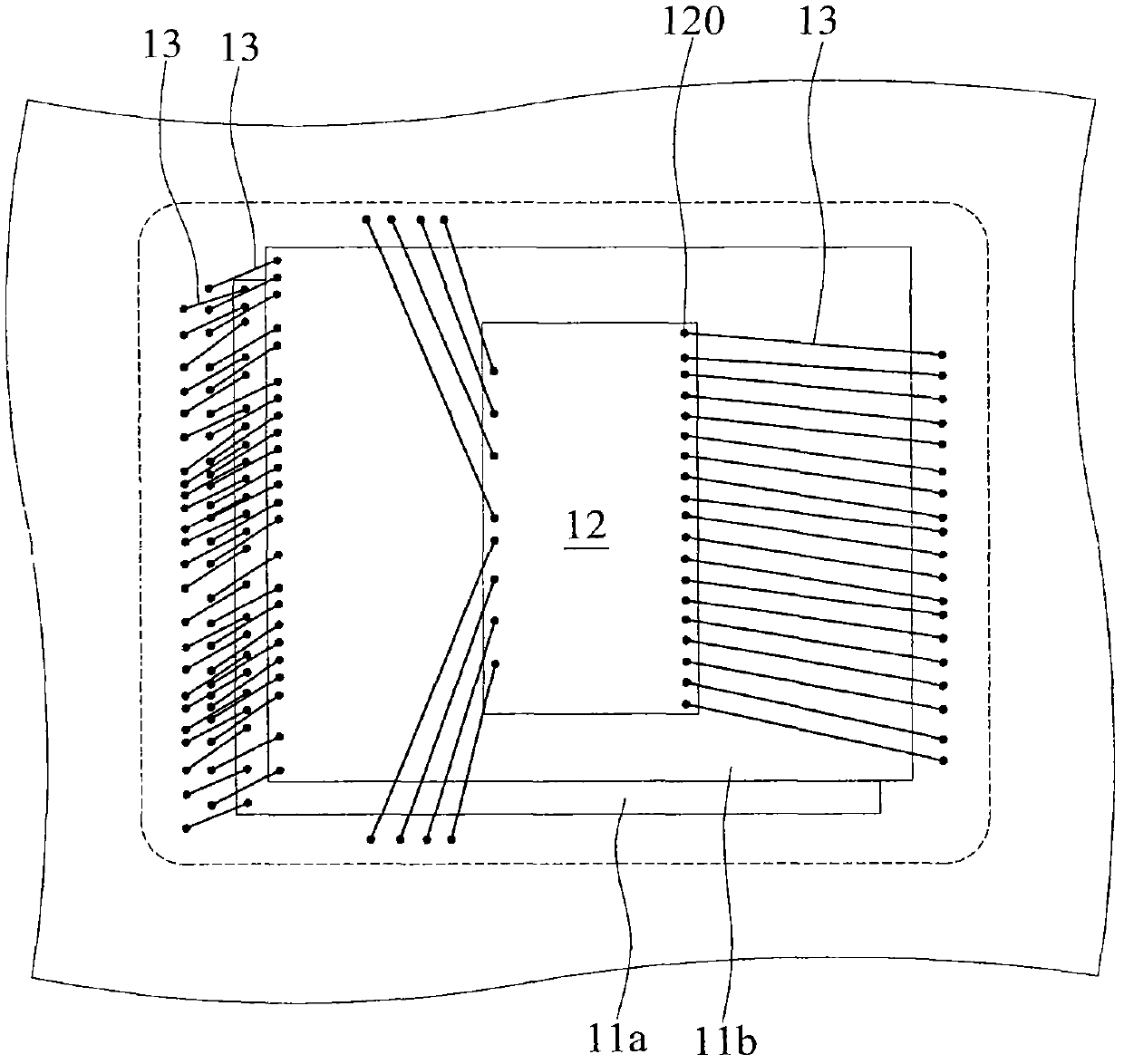

Biometric device

ActiveCN109389023AContributes to thinningContribute to thinning needsPrint image acquisitionLensOptoelectronicsMicro lens array

A biometric device includes an illuminating unit and an imaging module. The imaging module includes an optical angular selective structure and a sensing layer. The light selecting structure includes amicro lens array, a refractive layer and a light shielding layer. The refractive layer is disposed between the micro lens array and the light shielding layer. The micro lens array includes a plurality of lens unit units, and the light shielding layer has a plurality of light passing portions. The sensing layer defines multiple sensing regions which are spaced apart from each other. The light shielding layer is disposed between the refractive layer and the sensing layer. The sensing regions correspond to the light passing portions, respectively. An optical angular selective distance is definedbetween the light shielding layer and the sensing layer.

Owner:IND TECH RES INST

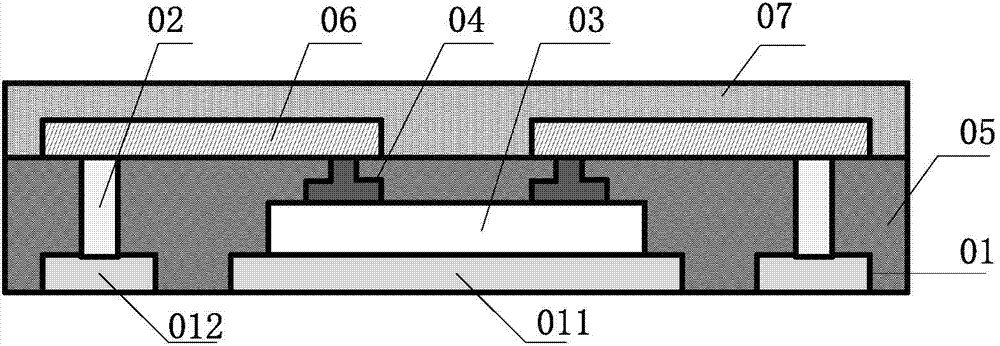

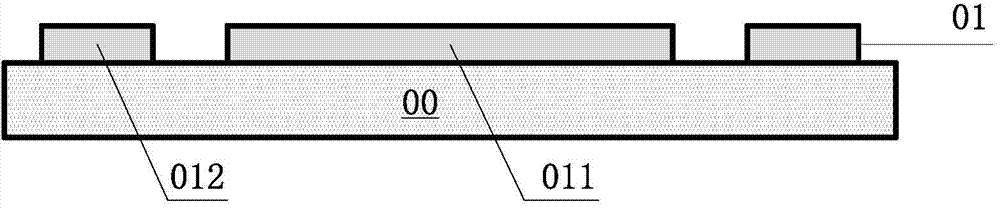

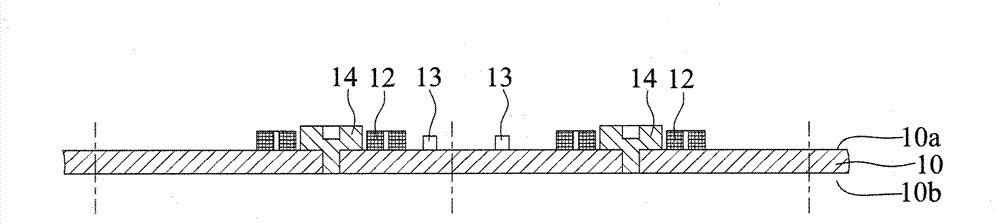

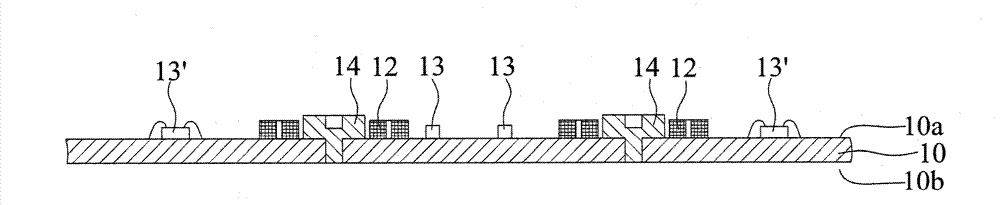

Chip packaging structure and manufacture method thereof

InactiveCN104779220AImprove reliabilityMeet the needs of thinningSemiconductor/solid-state device detailsSolid-state devicesSolderingExternal circuit

The invention provides a chip packaging structure and a manufacture method thereof. The chip packaging structure comprises a first pin, a first conductive post positioned on the first pin, and a second pin positioned on a second conductive post and electrically connected with the second conductive post and a first electric connecting body on a chip active surface, wherein an electrode bonding pad on the chip active surface is led out through a conductive path comprising the first electric connecting body, the second pin, the first conductive post and the first pin, and finally the electric connection between a chip and an external circuit is realized through the first pin. The mode for leading out the electrode can effectively reduce packaging resistance, does not need solder for welding, can avoid the phenomenon of pseudo soldering, improves the chip packaging reliability, and effectively reduces the chip packaging thickness.

Owner:HEFEI SMAT TECH CO LTD

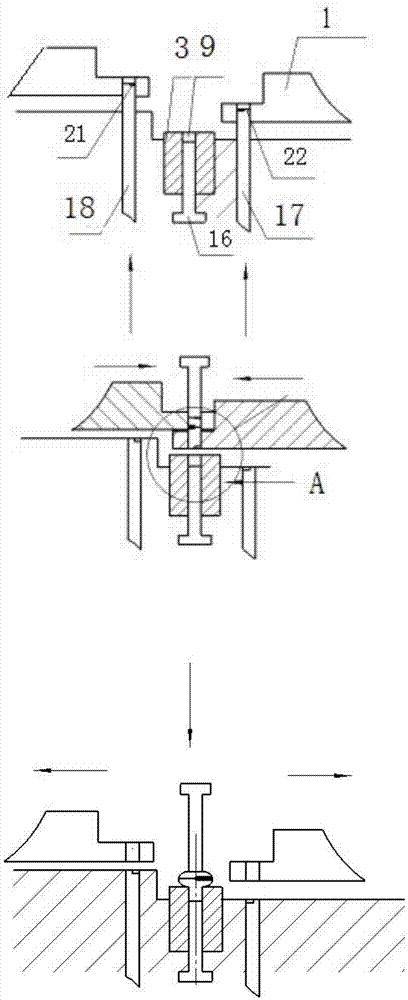

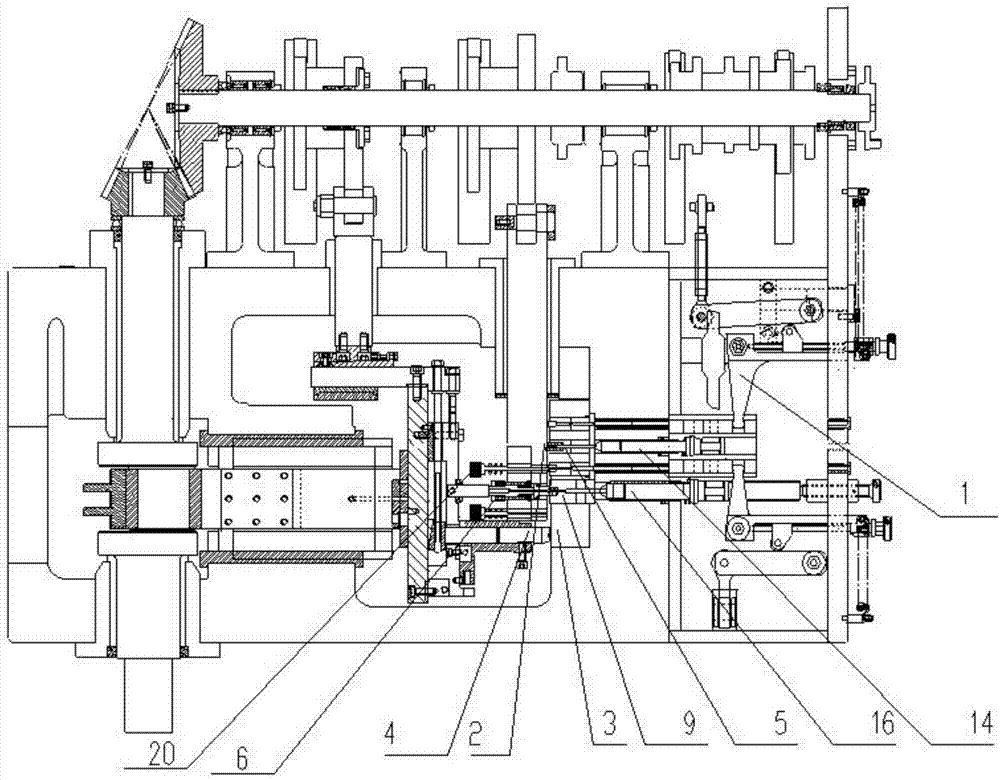

Composite electrical contact equipment applicable for manufacturing thin silver layers

ActiveCN107195494AOvercoming the lack of binding surfaceOvercome the limitation of not being thin enoughElectric switchesState of artCopper wire

The invention relates to composite electrical contact equipment applicable for manufacturing thin silver layers. The composite electrical contact equipment comprises a wire incoming device for conveying copper wires and silver wires with different wire diameters, a shearing rod capable of moving back and forth to shear the wires provided by the wire incoming device so as to cut the silver wires and the copper wires, a die holder which is fixed on the equipment and corresponds to the shearing rod, a final upsetting die for molding the wires into electrical contact products, a cam transmission device for controlling each component of the equipment to perform coordinated actions and the like; a storage die for independently storing the sheared silver wires is arranged on the die holder; and a control die for transferring the silver wires in the storage die, carrying out stained connection pre-upsetting on the copper wires in the die holder and then molding into the electrical contact products by using the final upsetting die is arranged on the shearing rod. The composite electrical contact equipment has the beneficial effects that the defect that the junction surfaces of silver and copper are insufficient existing due to trimming on two sides of a bottom die in the prior art is overcome, and simultaneously the defect that the thinning capacity is insufficient in the prior art is also overcome.

Owner:曾智丹

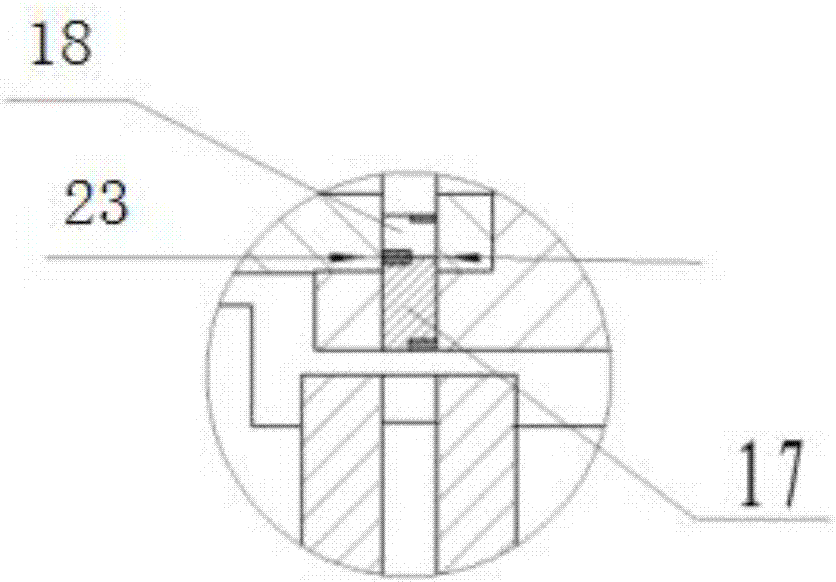

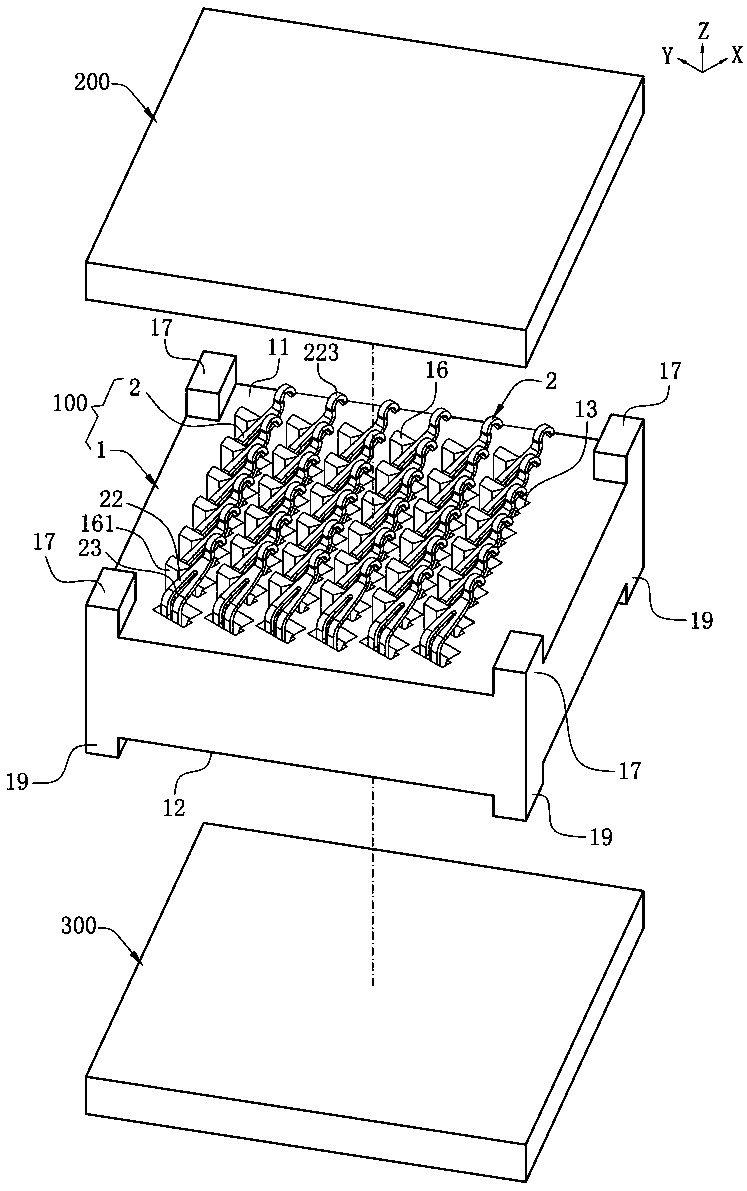

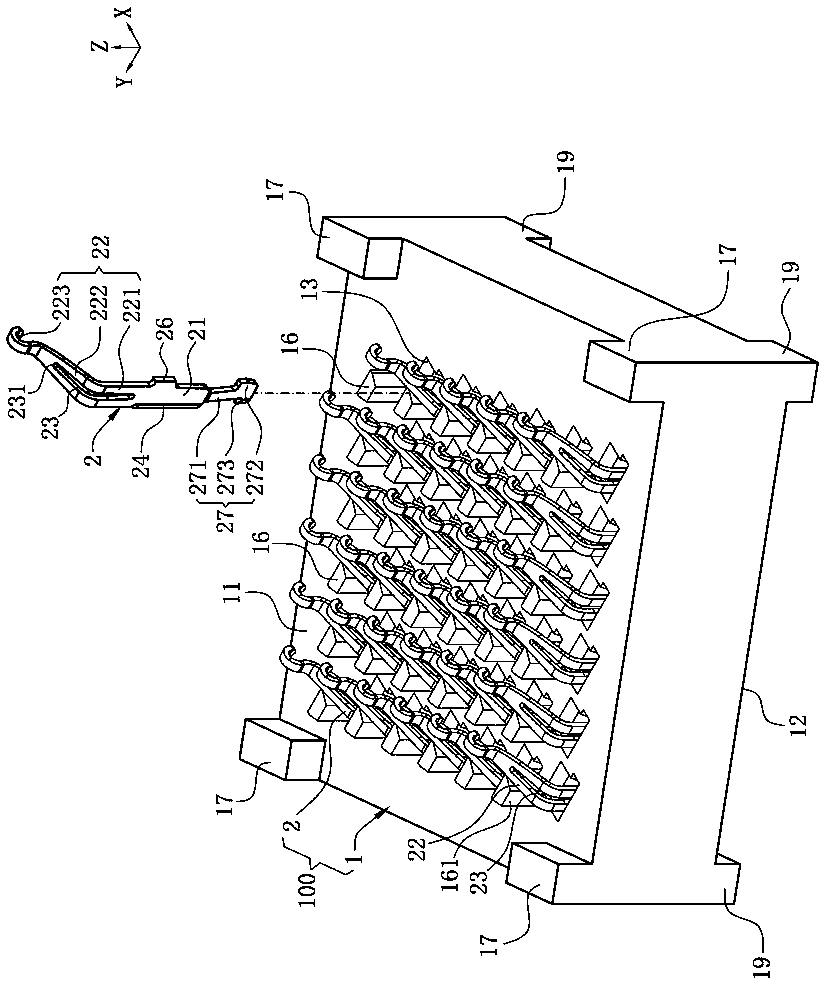

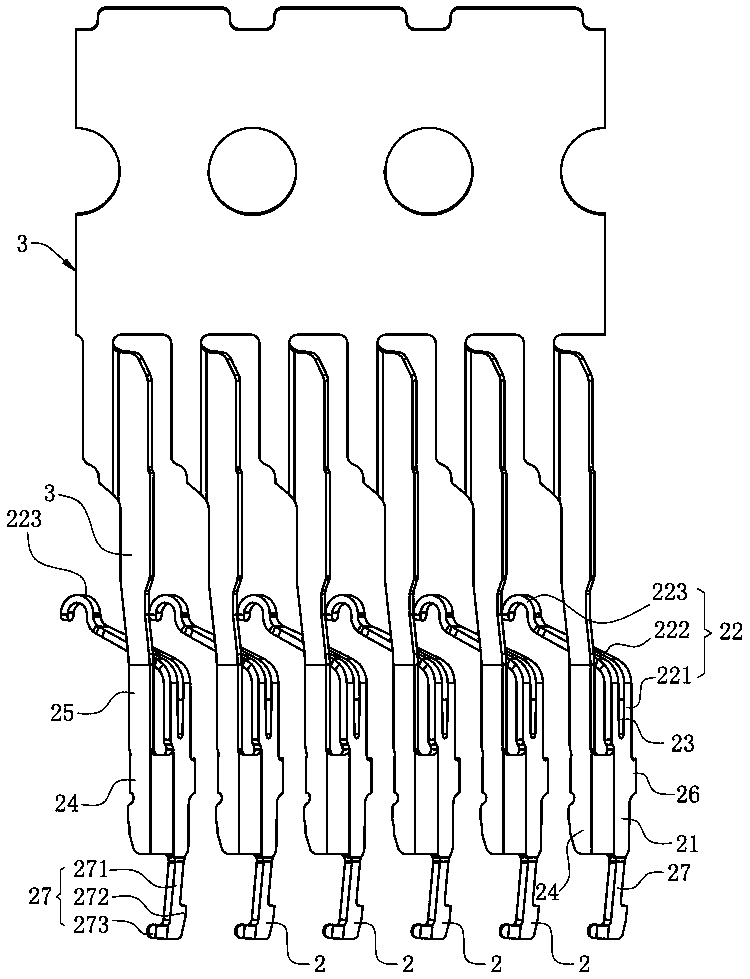

Electrical connector

ActiveCN109037988AContact stabilityMeet the needs of thinningElectric discharge tubesCoupling contact membersEngineeringElectrical connector

An electrical connector configured to electrically connect to a chip module includes: a body, provided with at least one accommodating hole, where the body has a protruding block provided to protrudeupward from one side of the accommodating hole, and the protruding block is configured to support the chip module upward; and at least one terminal, correspondingly accommodated in the at least one accommodating hole. The terminal includes a base, accommodated in the accommodating hole; an elastic arm, formed by extending forward from the base, located at one side of the protruding block, and configured to be electrically connected with the chip module; and a through slot, running vertically through the elastic arm. The protruding block has a rear end. The base is located behind the rear end,and the through slot extends forward beyond the rear end. On the premise that the length of the elastic arm is not changed, the elastic arm is resistant to fatigue, the electrical connector is thinned, when the chip module is downwards abutted on the elastic arm, two parallel conductive routes are formed on two opposite sides of the elastic arm with respective to the through slot, and thus the high frequency signal transmission performance of the terminal is improved.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

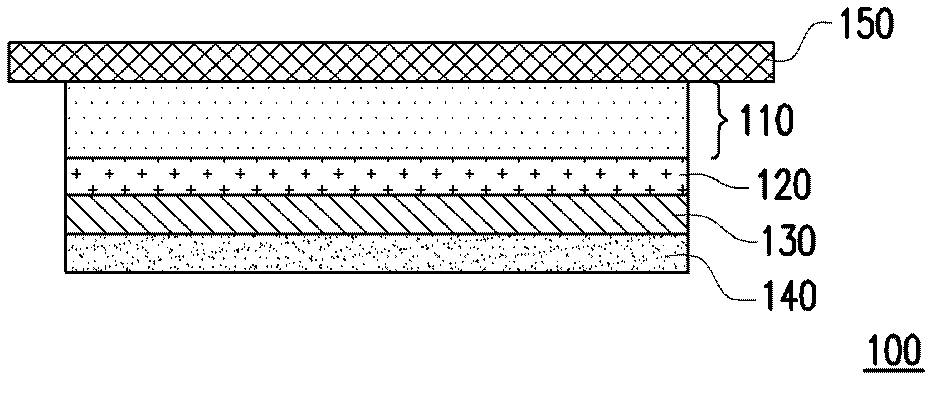

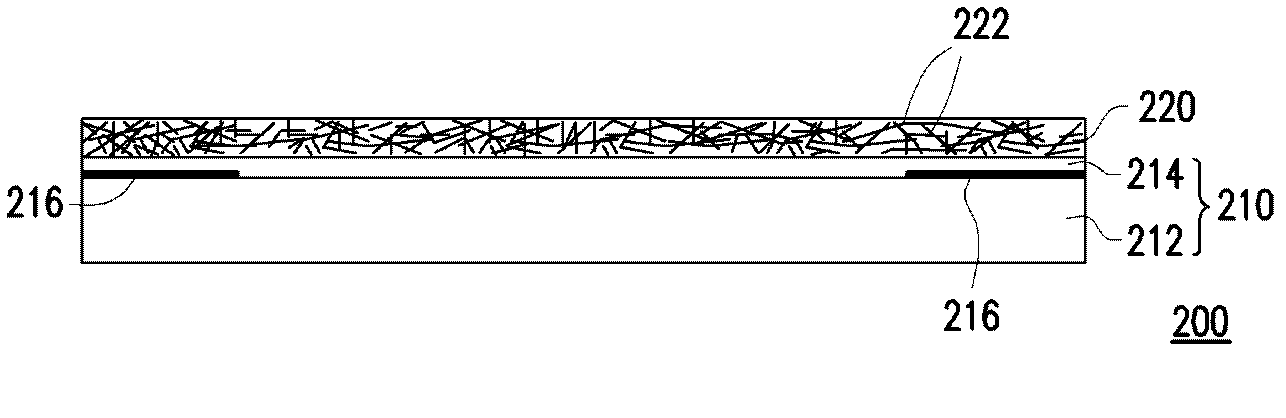

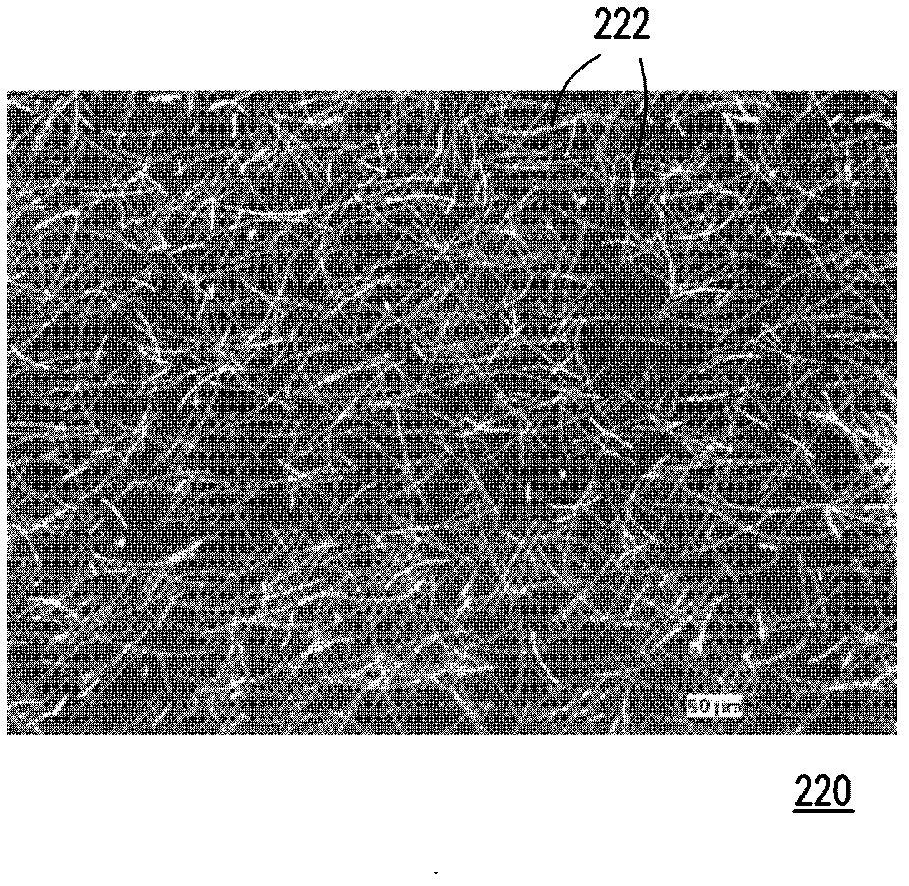

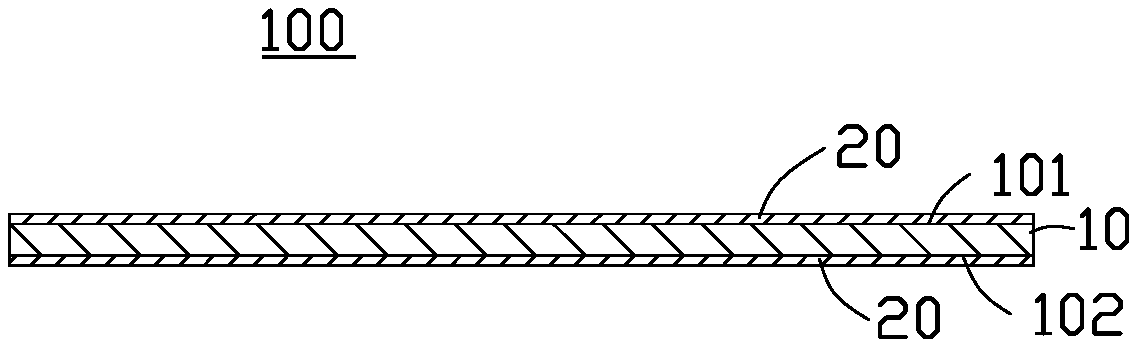

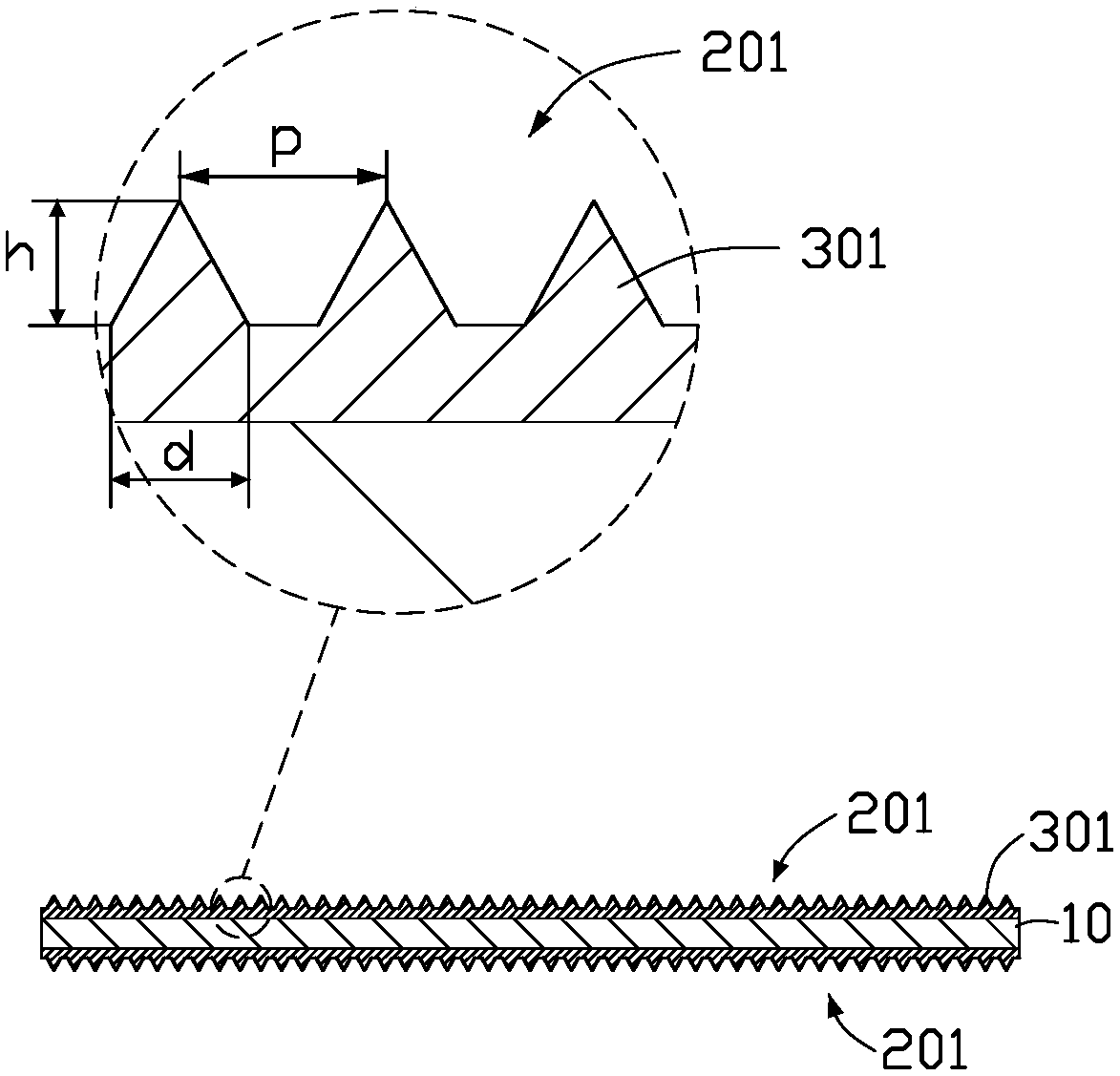

Touch device and touch display device

InactiveCN102855013AIncrease Penetration··Meet the needs of thinningInput/output processes for data processingDisplay deviceComputer science

A touch device comprises a touch panel and a shielding electrode film. The touch panel comprises a substrate and a touch element located on the substrate. The shielding electrode film is configured on the touch panel and is provided with a plurality of nanometer metal wires which are staggered to form the shielding electrode film. Therefore, the touch device can greatly reduce integral thickness. A touch display device with the structure is further provided.

Owner:WINTEK CHINA TECH LTD +1

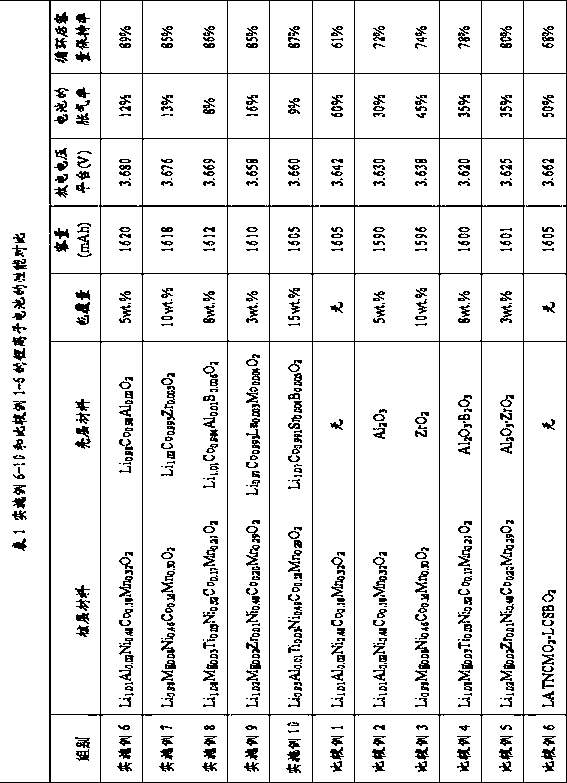

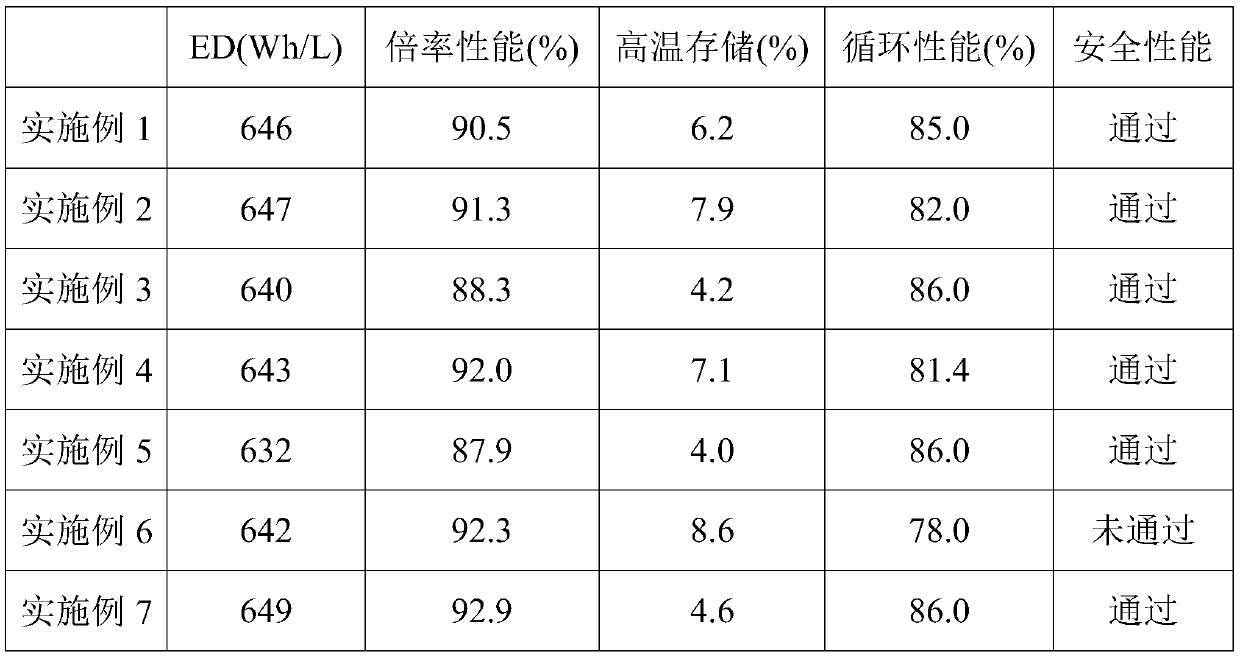

Positive electrode material and preparation method and application thereof

InactiveCN110112393AIncrease energy densityImproved magnification performanceCell electrodesSecondary cellsState of artDecomposition

The invention relates to a positive electrode material and a preparation method and application thereof. The surfaces of a core layer material A composed of secondary spherical particles and a singlecrystal particle core layer material B composed of the secondary spherical particles are coated with a shell layer material to form a material A and a material B respectively, and then the material Aand the material B are mixed, so that the energy density, the rate capability, the high-temperature cycle and the safety performance of the positive electrode material are remarkably improved. The core layer material is coated with the shell layer material, so that the residual alkali of the positive electrode material can be remarkably reduced, the oxidative decomposition of the positive electrode material on the electrolyte is reduced, and the high-temperature cycle and safety performance of the positive electrode material are improved. Compared with the prior art, a lithium ion battery obtained by the invention can achieve very good energy density, cycle performance and safety performance under higher voltage (greater than or equal to 4.2V vs (Li + / Li)). Due to the fact that the charging cut-off voltage is increased, the battery has high energy density, and the requirement of people for thinness of the lithium ion battery can be met.

Owner:东莞维科电池有限公司

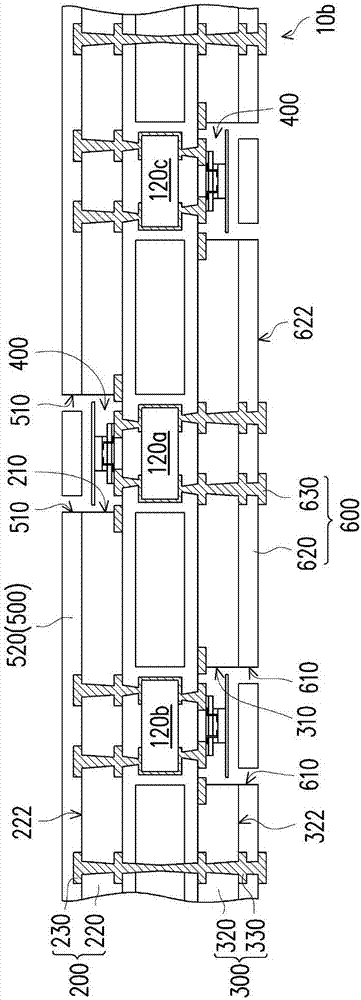

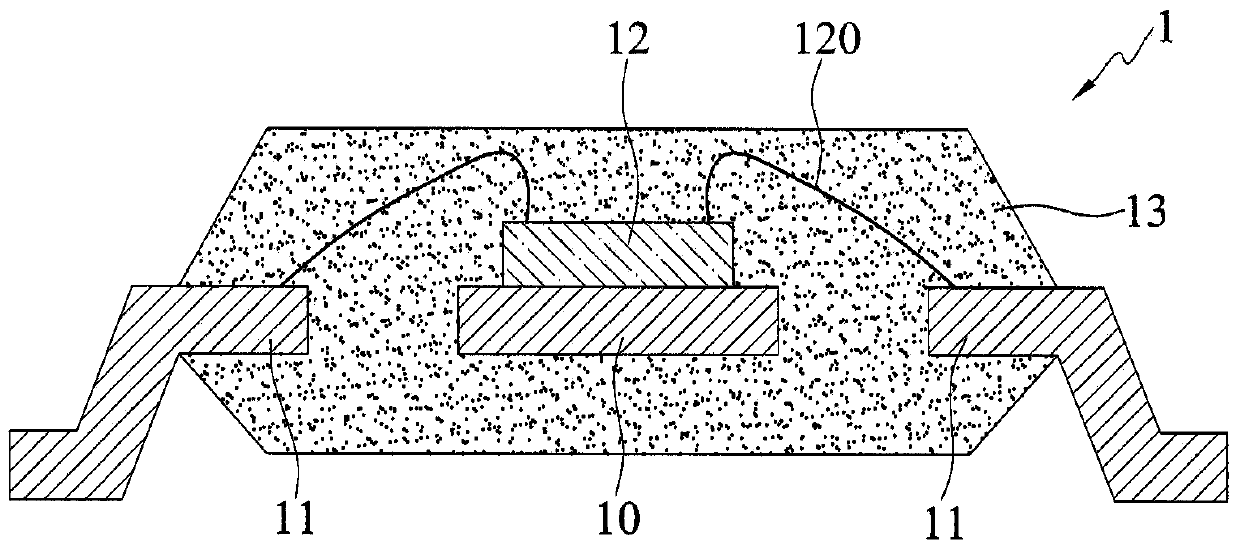

Semiconductor package with cooling fan and its stack structure

InactiveCN102290389AReduce thicknessHigh outputSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention discloses a semiconductor packaging component with a cooling fan and a manufacturing method and a stacking structure thereof. The semiconductor packaging component with the cooling fan comprises a substrate, an electronic element, a packaging rubber body and a fan unit, wherein the substrate is provided with a first surface and a second surface, the first surface is provided with a fan arrangement area, the fan arrangement area of the substrate is provided with an open hole and a ventilation hole penetrating through the substrate; the electronic element is arranged on the first surface and around the fan arrangement area and is electrically connected with the substrate; the packaging rubber body is formed on the electronic element and the first surface of the substrate and is provided with a packaging rubber body opening for the exposure of the fan arrangement area; and the fan unit is arranged in the packaging rubber body opening and is electrically connected with the substrate. Since the electronic element is arranged on the part of the substrate outside the fan arrangement area, when the fan unit operates normally, heat produced by the electronic element can be effectively dissipated and can be prevented from being damaged as a result of overheating, and the overall height of the fan unit can be reduced.

Owner:AMTEK SEMICON

Reflecting type electrochromic liquid crystal display (LCD)

InactiveCN101852959AImprove reflection efficiencyAchieve colorful display effectNon-linear opticsElectric fieldWavelength

The invention discloses a reflecting type electrochromic liquid crystal display (LCD) which comprises a first base plate, a second base plate, a first electrochromic liquid crystal mixture layer, a first electrode layer and a second electrode layer, wherein the second base plate is parallel to the first base plate, and the first electrochromic liquid crystal mixture layer is configured between the first base plate and the second base plate and comprises a plurality of liquid crystal molecules, an optical rotating agent and a macromolecule mixture; the liquid crystal molecules and the optical rotating agent are distributed in a curing structure of the macromolecule mixture; the first electrode layer is configured between the first base plate and the first electrochromic liquid crystal mixture layer, and the second electrode layer is configured between the second base plate and the first electrochromic liquid crystal mixture layer; the first electrochromic liquid crystal mixture layer reflects first reflecting light, and the wavelength of the first reflecting light is changed along with a first electric field between the first electrode layer and the second electrode layer.

Owner:WINTEK CORP

Positive electrode material, preparation method thereof, and lithium ion battery comprising the positive electrode material

ActiveCN103137961BIncrease volumetric energy densityMeet the needs of thinningElectrode thermal treatmentLi-accumulatorsSurface layerSodium-ion battery

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a positive electrode material. The positive electrode material is formed by melting a bulk phase material and a surface layer material located on the surface of the bulk phase material. The bulk phase material is lithium cobaltate, and the surface layer material is layered nickel manganese Lithium oxide is composed of molten small particles, and the surface layer material accounts for 0.1-10% by mass of the positive electrode material. Compared with the prior art, the positive electrode material formed by coating the layered lithium nickel manganese oxide on the surface of the lithium cobalt oxide in the present invention has excellent lithium ion conductivity, not only does not reduce the discharge voltage platform of the positive electrode material, but instead To a certain extent, the discharge voltage platform of the positive electrode material can be improved; and the coating layer can also exert an effective gram capacity under high voltage, and enhance the structural stability of the matrix material, thereby significantly improving the discharge of the positive electrode material under high voltage. capacity and cycle life. In addition, the invention also discloses a preparation method of the cathode material and a lithium ion battery containing the cathode material.

Owner:DONGGUAN AMPEREX TECH

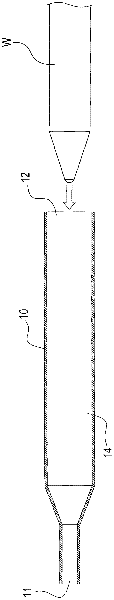

Cross-under type heat pipe structure and manufacturing method thereof

InactiveCN102636058ADry burning will not occurFast heat conductionIndirect heat exchangersEngineeringHeat pipe

The invention discloses a cross-under type heat pipe structure and a manufacturing method of the cross-under type heat pipe structure. The cross-under type heat pipe comprises a first heat pipe and a second heat pipe, wherein the first heat pipe comprises a first pipe body, a first capillary organization and a first operating fluid, wherein the first pipe body is provided with a hollow containing cavity and an opening; the first capillary organization is arranged on the wall surface of the hollow containing cavity, and the first operating fluid is filled in the hollow containing cavity; the second heat pipe penetrates into the first pipe body from the opening, one part of region of the second heat pipe is contained and sealed in the hollow containing cavity, and a gas channel is formed between the outer wall of the second heat pipe and the inner wall of the first pipe body; and the cross-under type heat pipe structure formed by the first heat pipe and the second heat pipe through cross under is suitable for long-range heat conduction, and the heat conduction efficiency is improved.

Owner:KUNSHAN JUZHONG ELECTRONICS

High-voltage lithium-ion battery cathode material and lithium-ion battery comprising the material

ActiveCN103066282BMeet the needs of thinningIncrease volumetric energy densityCell electrodesSecondary cellsMass ratioCore shell

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a high-voltage anode material for a lithium ion battery. The anode material comprises a material A and a material B, wherein the material A has a core-shell structure, a core layer material is lithium cobalt oxide particles formed by primary particles, the median particle diameters D50 of the lithium cobalt oxide particles are 15-25 microns, and the structure formula of a core-shell material is LixNiyMnzPO4; the material B has a core-shell structure, the core layer material is the lithium cobalt oxide particles formed by secondary particles, and the median particle diameters D50 of the lithium cobalt oxide particles are is 3-9 microns; and the structure formula of the core-shell material is LiwAlpZrqO2, and the mass ratio of the material A to the material B is (0.1-10) to 1. Compared with the prior art, the high-voltage anode material for the lithium ion battery provided by the invention has the advantages that the large and small lithium cobalt oxide particles are combined reasonably, different core layer materials can be arranged on the surfaces of the lithium cobalt oxide particles, and the secondary particles are selected as the small lithium cobalt oxide particles, so that the cycle performance and the safety performance of the anode material under high voltage are notably improved.

Owner:DONGGUAN AMPEREX TECH

Glasses lens

InactiveCN109884736AMeet the needs of thinningHigh transparencySpectales/gogglesOptical partsUses eyeglassesEyewear

The invention relates to a glass lens which comprises an eyeglass body and a functional film layer formed on at least one surface of the eyeglass body, wherein the main component of the eyeglass bodyis a cyclic-block-copolymer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

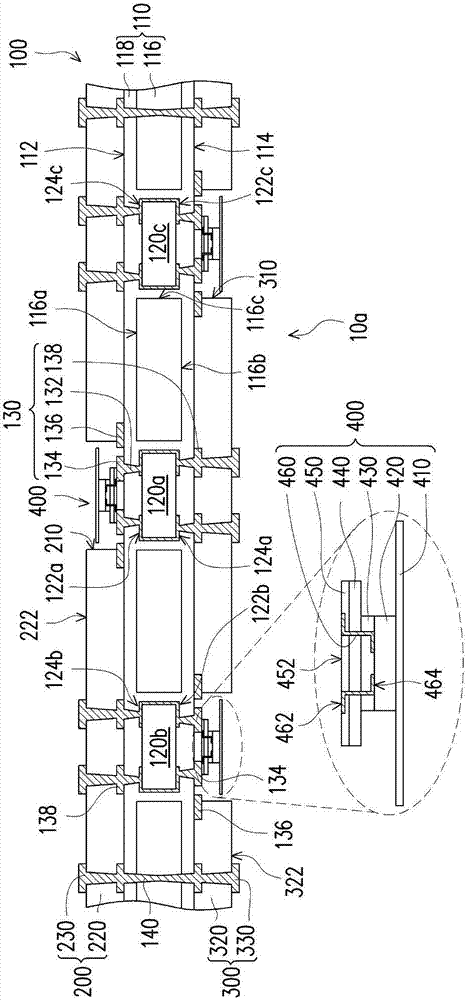

Image module and manufacturing method thereof

InactiveCN103474440AReduce the overall height of the moduleMeet the needs of thinningRadiation controlled devicesAnisotropic conductive adhesiveThermal compression

The invention discloses an image module and a manufacturing method thereof. The image module comprises a lens assembly, an image sensing component, an anisotropic conductive adhesive and a circuit board. The circuit board possesses a first plate surface and a second plate surface. The image sensing component is arranged on the second plate surface. The lens assembly is arranged on the first plate surface. The anisotropic conductive adhesive is arranged between the second plate surface of the circuit board and the image sensing component so that the image sensing component is electrically connected to the circuit board. The manufacturing method of the image module comprises the following steps that the anisotropic conductive adhesive is coated on the second plate surface; thermal compression bonding processing is performed on the image sensing component and the anisotropic conductive adhesive so that the image sensing component is fixedly connected and electrically connected with the second plate surface; the lens assembly is arranged on the first plate surface and the image sensing component is packaged.

Owner:BISON ELECTRONICS

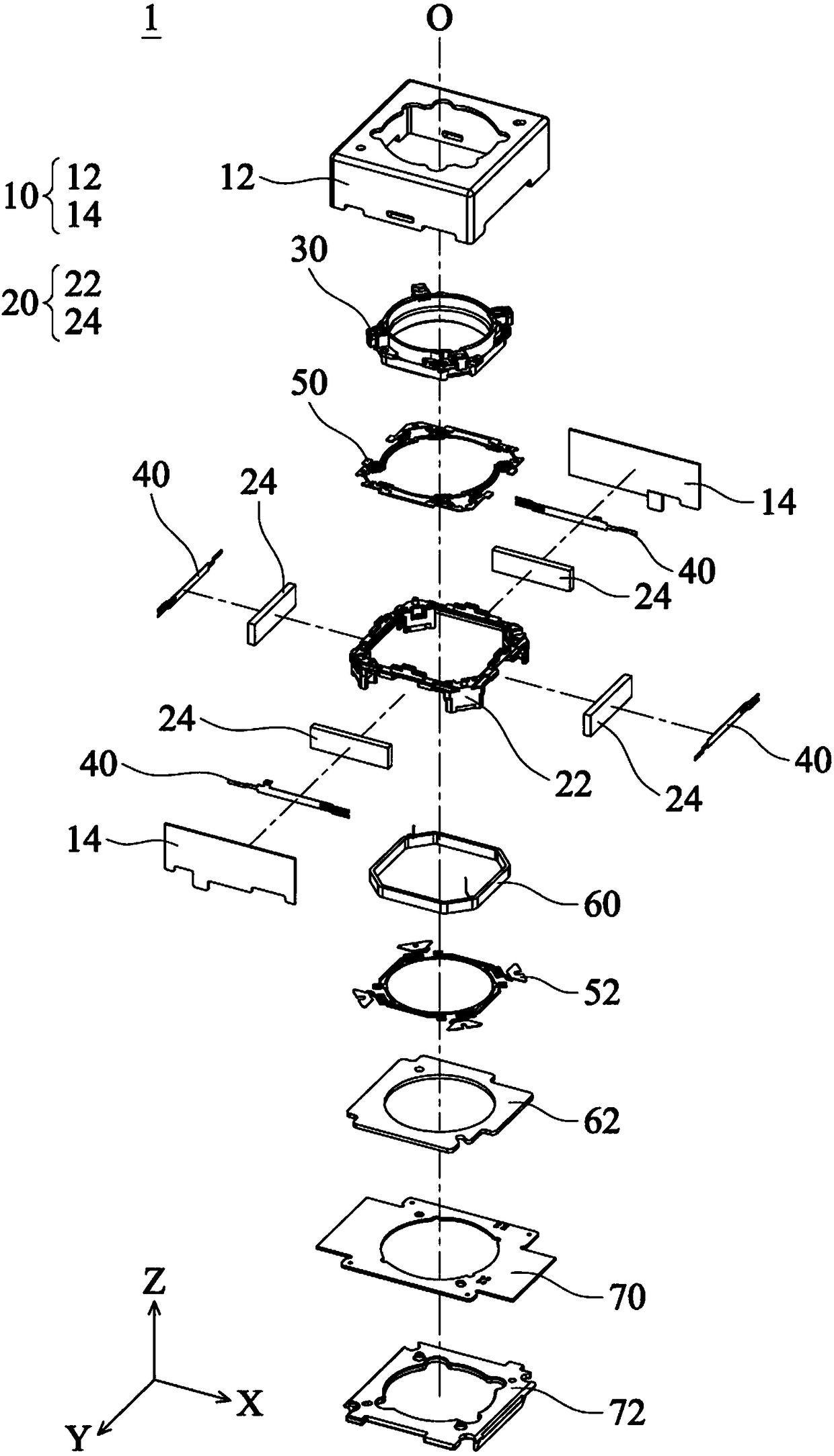

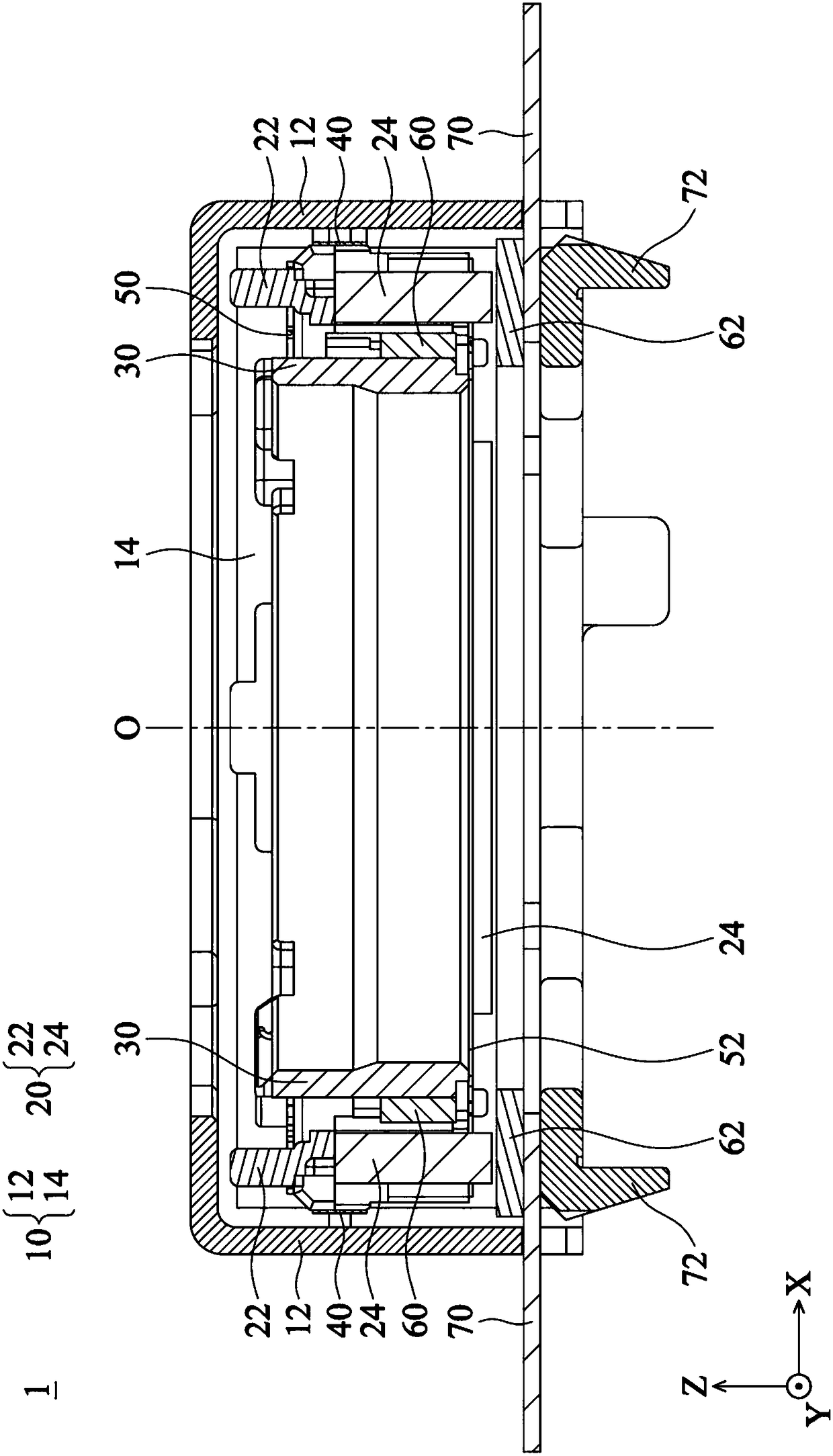

Support mechanism

ActiveCN108345081ALower the altitudeMeet the needs of thinningPrintersProjectorsEngineeringMechanical engineering

Owner:TDK TAIWAN

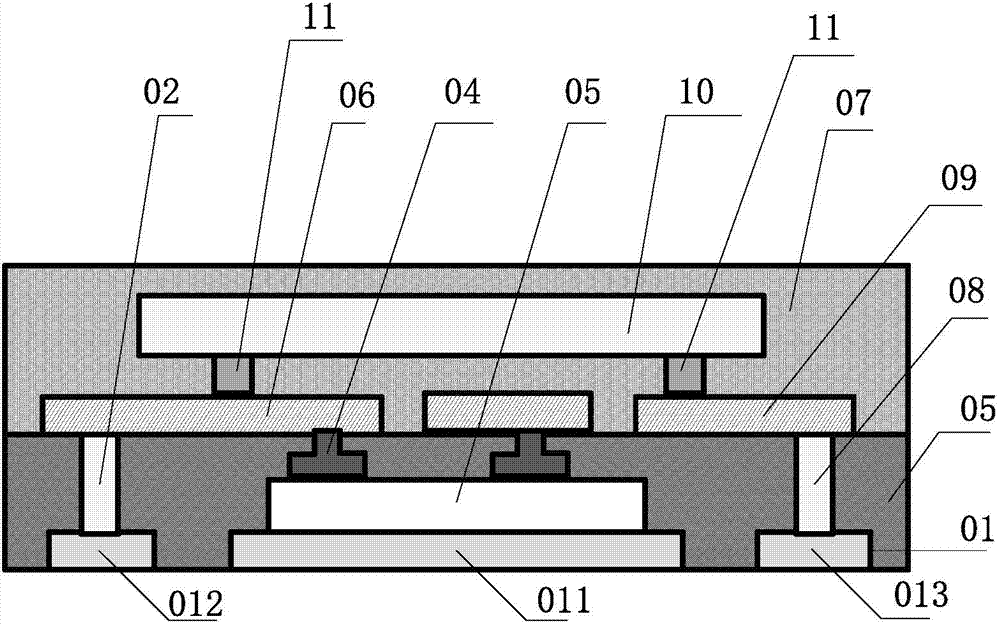

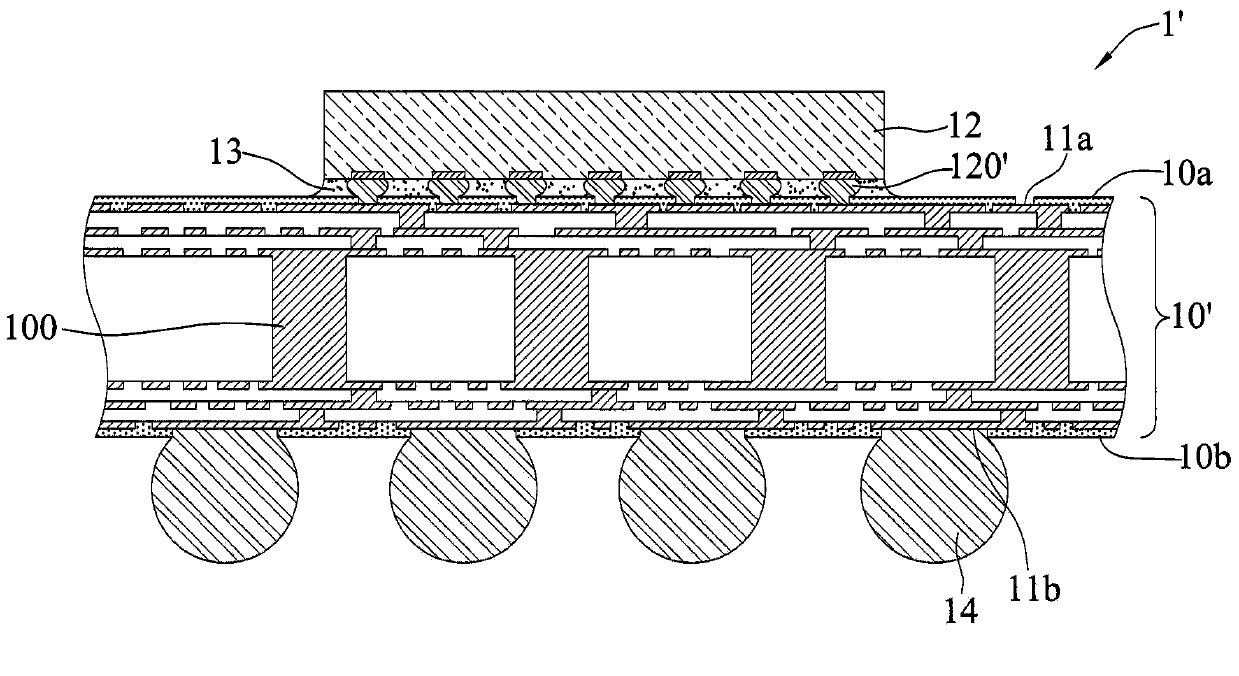

Packaging structure and manufacturing method thereof

ActiveCN107978575AAvoid electromagnetic interferenceThin Package ThicknessSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

The invention relates to a packaging structure and a manufacturing method thereof. The packaging structure comprises a circuit substrate, a first layer-adding line structure, a second layer-adding line structure, and a plurality of piezoelectric heat radiating units. The circuit substrate comprises a core layer, a plurality of electronic components, and a conducting unit. The electronic componentsare imbedded in the core layer, and the active surfaces of two adjacent electronic components respectively face towards the a first surface and a second surface of the core layer. The conducting unitis configured to the core layer and is electrically connected to the electronic components. The first and second layer-adding line structure are respectively configured to the first and second surface, and are respectively provided with at least one first opening and one second opening. Each piezoelectric heat radiating unit is corresponding to the active surface of the electronic component, andis electrically connected to the conducting unit, exposing from the first opening and the second opening. The invention is advantageous in that the electromagnetic wave interference among the electronic components can be prevented; the packaging is thin and volume can be small; the thin-type demand can be met.

Owner:UNIMICRON TECH CORP

Semiconductor package

InactiveCN102891137AImprove performanceIncrease the number ofSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

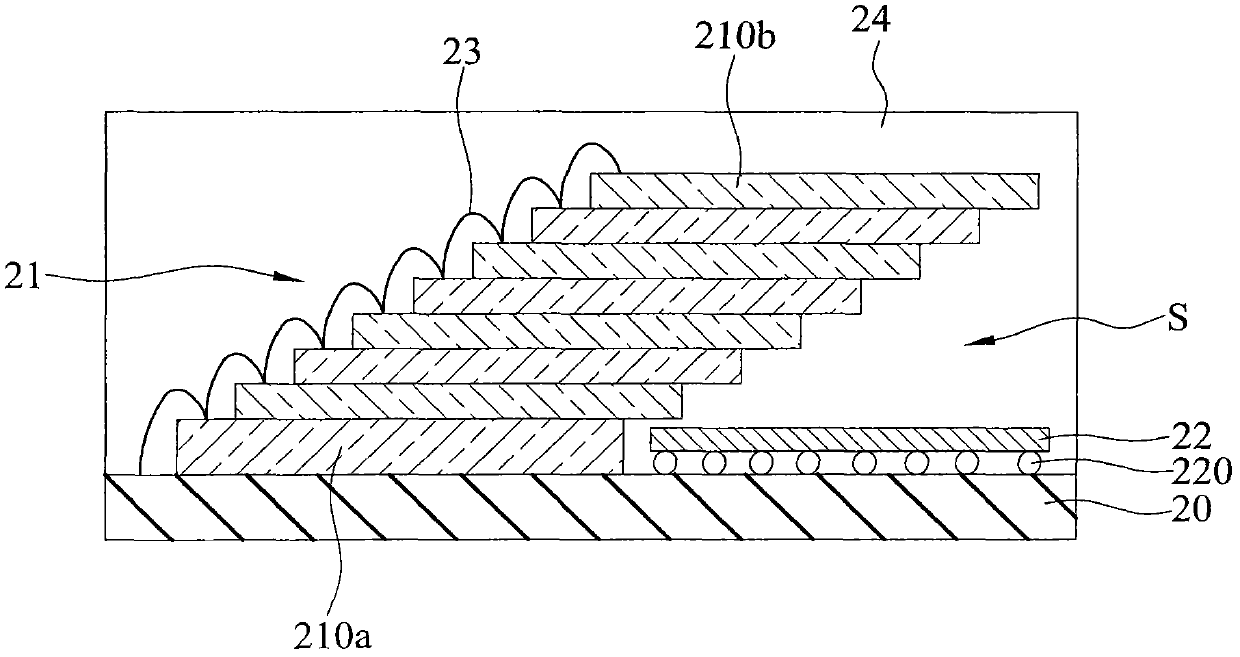

A semiconductor package comprises a packaging substrate; a plurality of semiconductor chips stacked on the packaging substrate in a stagger manner, forming an accommodation space between the packaging substrate and the stacked semiconductor chips; and a control chip integrated with the packaging substrate by flip chip technology and positioned in the accommodation space. As the control chip is arranged in the accommodation space, the thickness of the whole package is reduced so as to achieve the purpose of thinning.

Owner:SILICONWARE PRECISION IND CO LTD

Backlight module and manufacturing method therefor

ActiveCN101082740AHigh strengthMeet the needs of thinningNon-linear opticsEngineeringUltimate tensile strength

Owner:AU OPTRONICS CORP

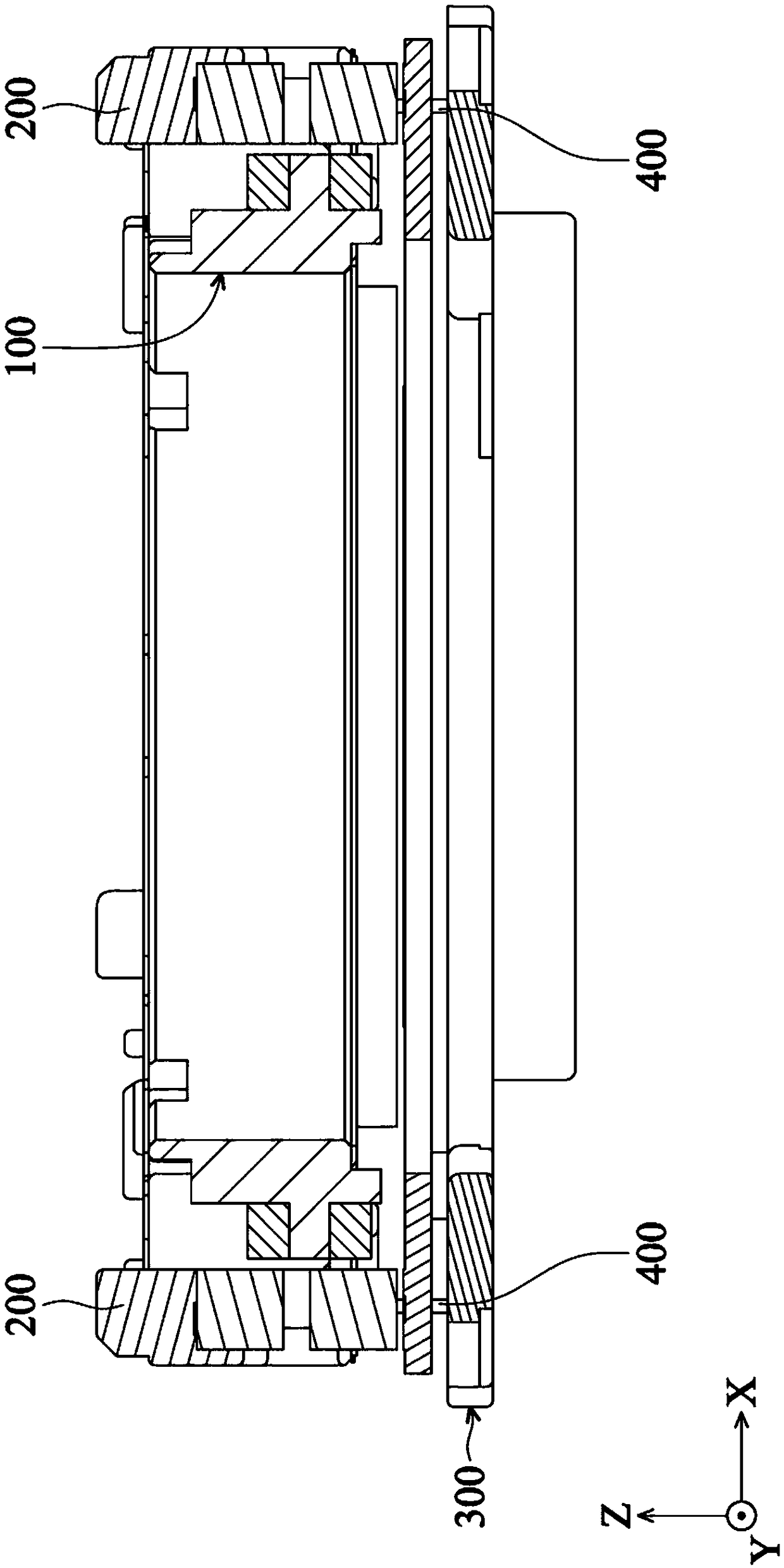

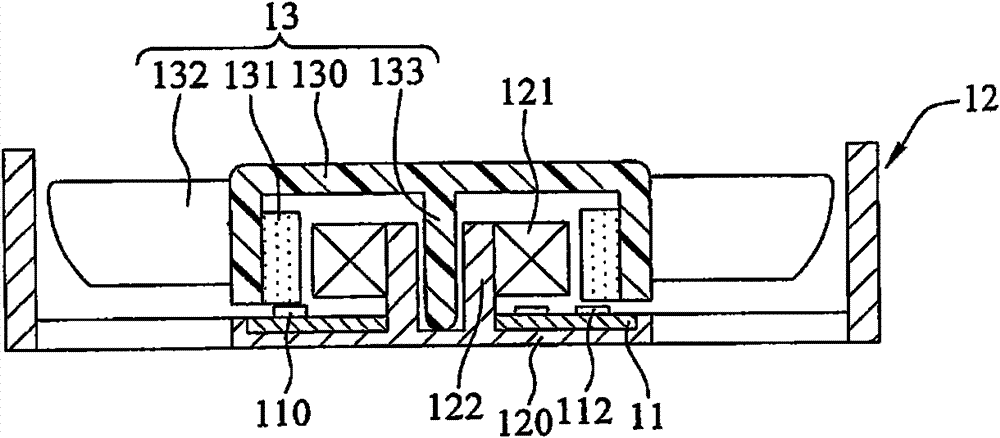

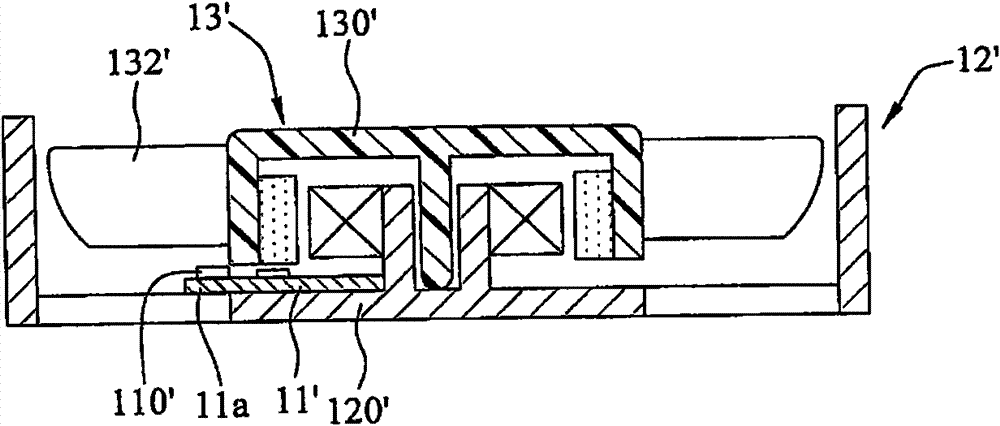

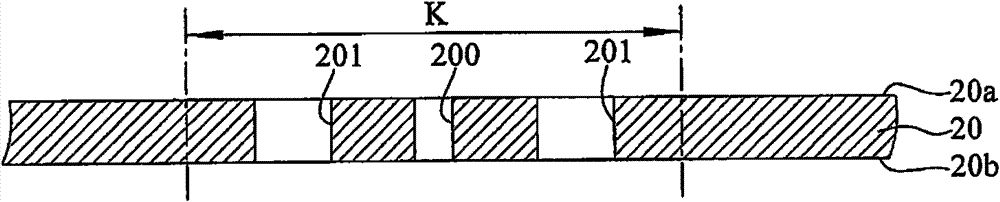

Motor and electronic device

ActiveCN113765432ASimple structureEasy to assembleReciprocating/oscillating/vibrating magnetic circuit partsPiezoelectric/electrostriction/magnetostriction machinesHemt circuitsWorking environment

The invention provides a motor and an electronic device, and the motor comprises a shell, a first electric vibration part, and a mass block. The shell is internally provided with a containing cavity, the first electric vibration part and the mass block are arranged in the containing cavity, the first end of the first electric vibration part is connected with the shell, and the second end of the first electric vibration part is connected with the mass block. When the voltage is applied to the first electric vibration part, the first electric vibration part drives the mass block to move. According to the structure of the motor, the magnetic steel and a coil are omitted, so that magnetic field interference on the circuits and devices around the motor is avoided, and the working environment of the circuits and the devices around the motor is purified; meanwhile, the motor in the embodiment is simple in structure and is convenient to assemble and automatically produce; and in addition, due to the fact that the occupied space of the motor is small, the requirement for thinning the electronic device can be better met.

Owner:VIVO MOBILE COMM CO LTD

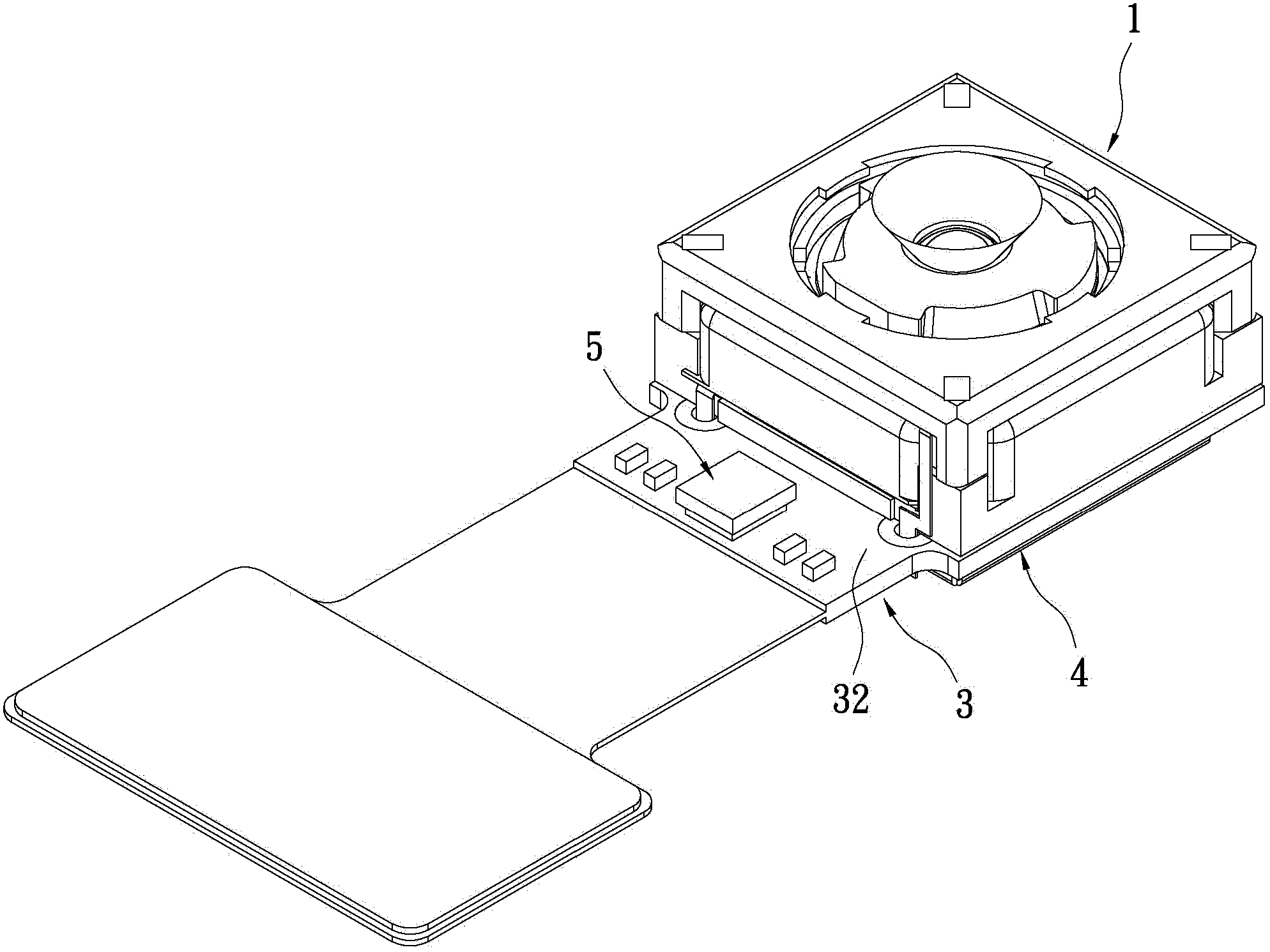

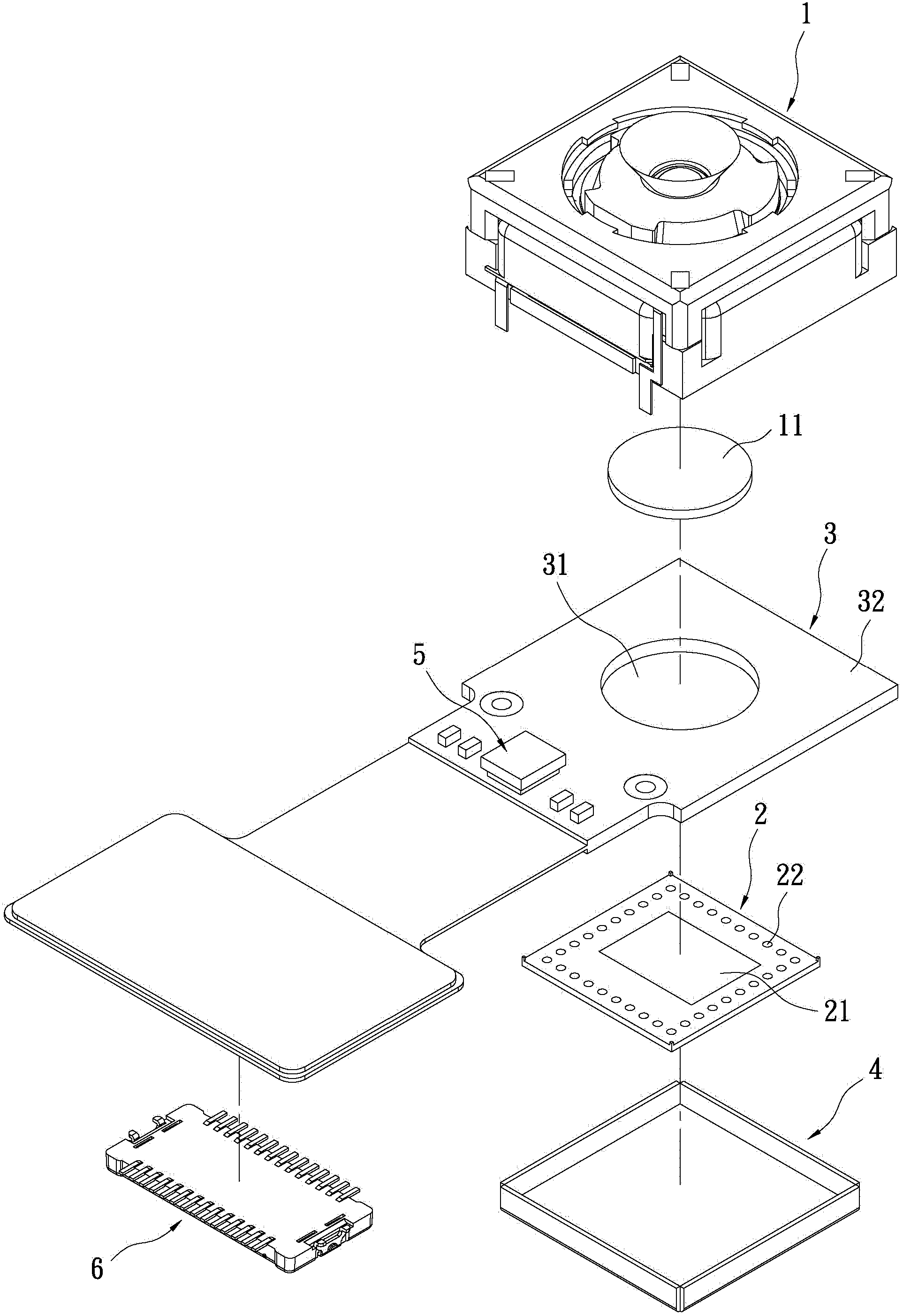

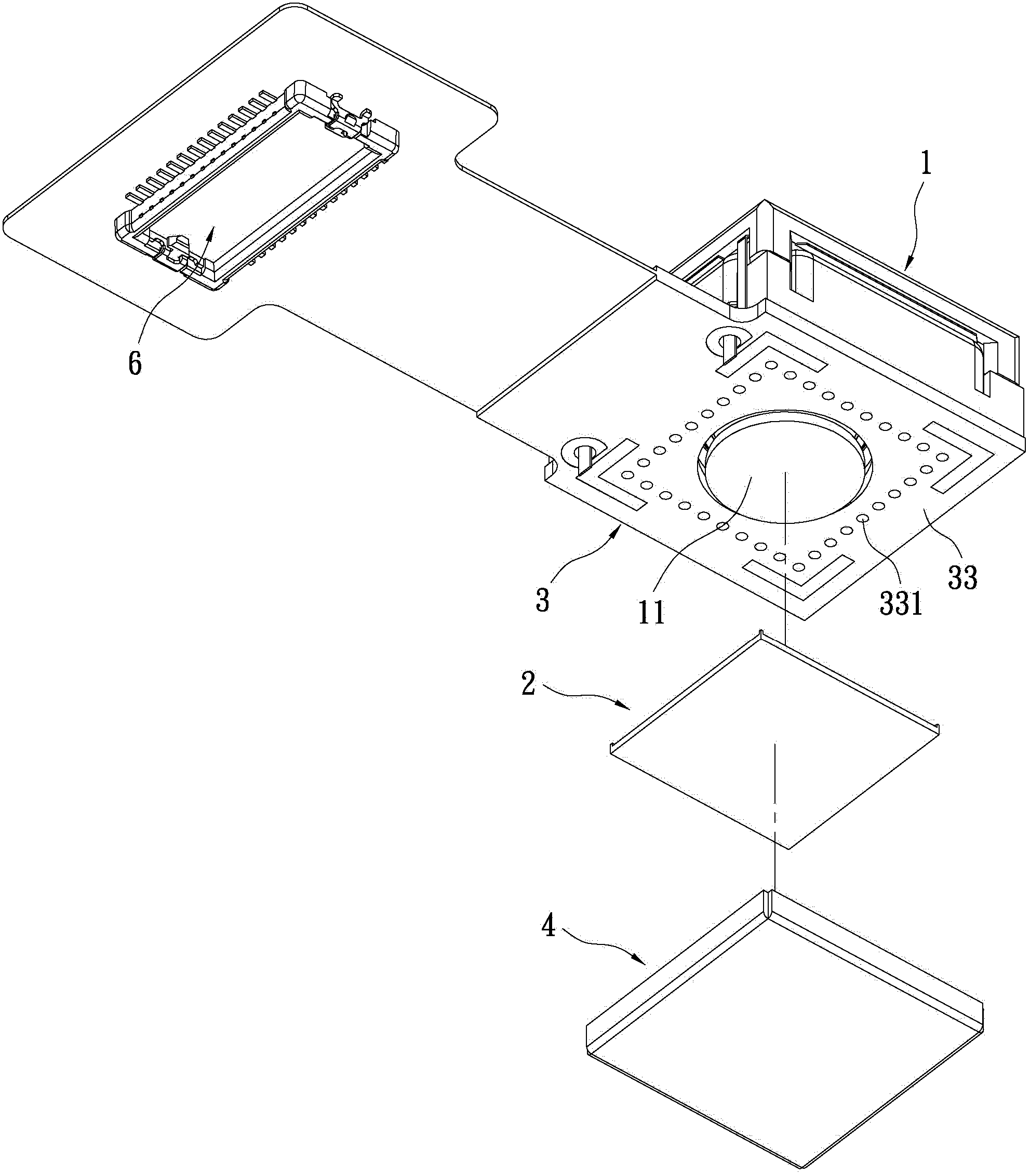

Semiconductor package member and fabrication method thereof

ActiveCN102956585ACannot be effectively escapedMeet the needs of thinningSemiconductor/solid-state device detailsSolid-state devicesNoise generationSemiconductor package

The present invention relates to a semiconductor package member and a fabrication method thereof, wherein the semiconductor package is provided for carrying a sleeve member and a fan wheel axially coupled to the sleeve member so as to provide a heat dissipating function. The semiconductor package member includes: a substrate; a stator module and at least an electronic component disposed on the substrate; and an encapsulant formed on the substrate for encapsulating the coil module and the electronic component so as to prevent the coil module and the electronic component from disturbing air flow generated by the fan wheel during operation, thereby avoiding generation of noises or vibrations.

Owner:AMTEK SEMICON

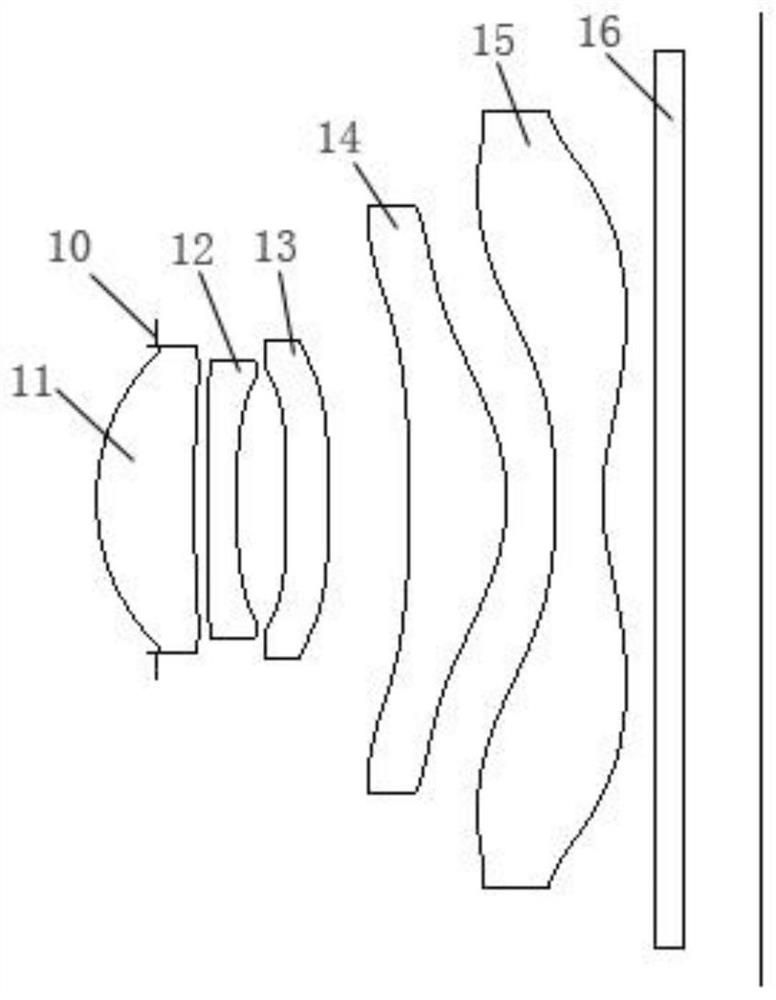

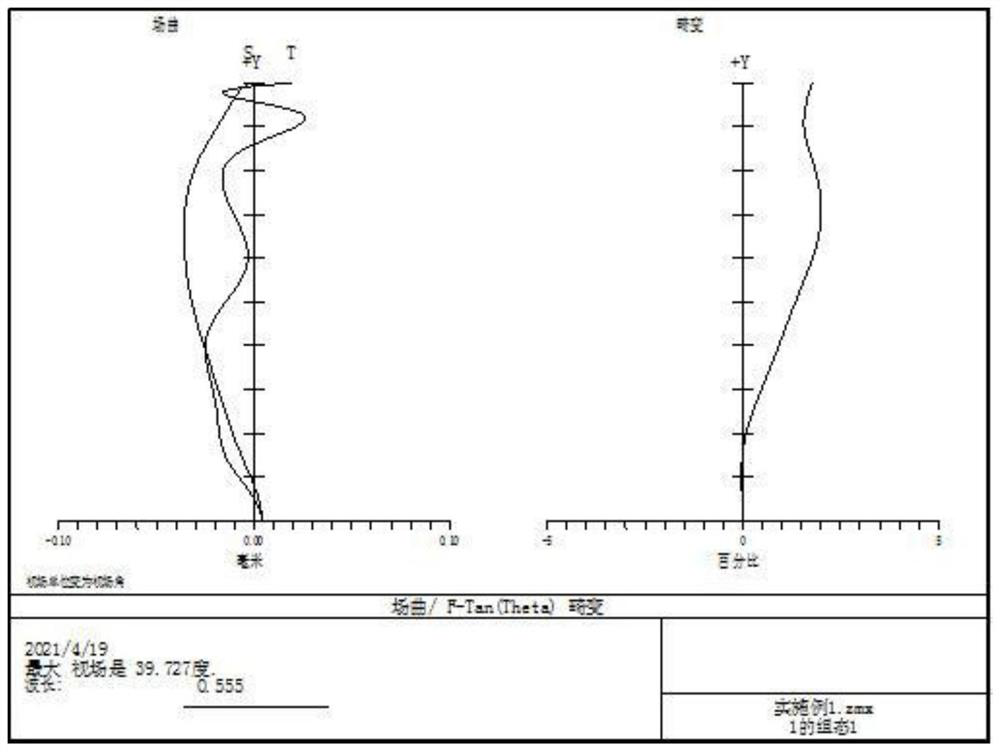

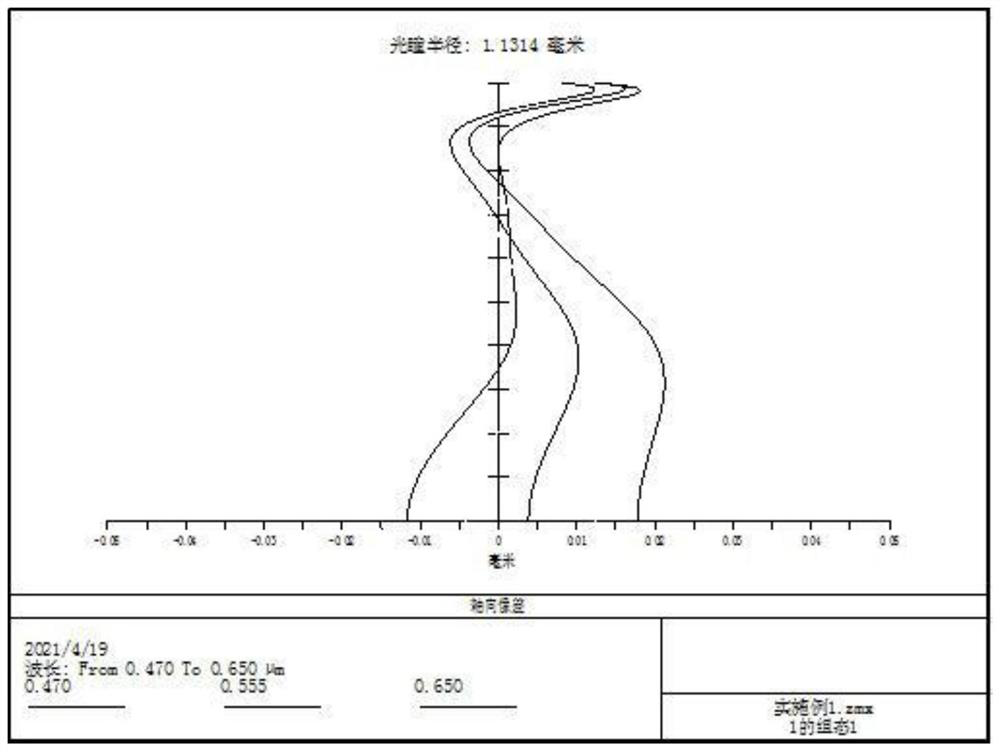

Five-piece type high-pixel imaging lens

PendingCN113156625AHigh image qualityShorten the overall lengthOptical elementsOphthalmologyNegative refraction

The invention relates to a five-piece type high-pixel imaging lens, and the five-piece type high-pixel imaging lens is composed of five lenses. The five-piece type high-pixel imaging lens sequentially comprises a first lens with positive refraction power, a second lens with negative refraction power, a third lens with positive refraction power or negative refraction power, a fourth lens with positive refraction power and a fifth lens with negative refraction power from an object side to an image side, and meets the following relational expressions: ImgH / Fno is greater than 1.91, wherein ImgH is half of the length of a diagonal line of an effective imaging area of the five-piece type high-pixel imaging lens, and Fno is the aperture number of the five-piece type high-pixel imaging lens. The five-piece type high-pixel imaging lens is high in imaging quality and light and thin in size, and has a large aperture and a large field angle.

Owner:HUIZHOU SAGETECH OPTRONICS CO LTD

Package structure and method of fabricating the same

InactiveCN105514081AShorten the signal transmission pathReduce signal lossSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

A package structure and a method for fabricating a package structure are provided. The method includes the steps of forming a wiring layer on a carrier by electroplating; disposing at least one electronic component on the wiring layer; forming on the carrier an insulating layer that encapsulates the wiring layer and the electronic component; and removing the carrier. With the single wiring layer having one surface electrically connected the at least one electronic component and the other surface electrically connected to a plurality of conductive elements, the package structure has a signal transmission path that is shortened.

Owner:PHOENIX & CORP

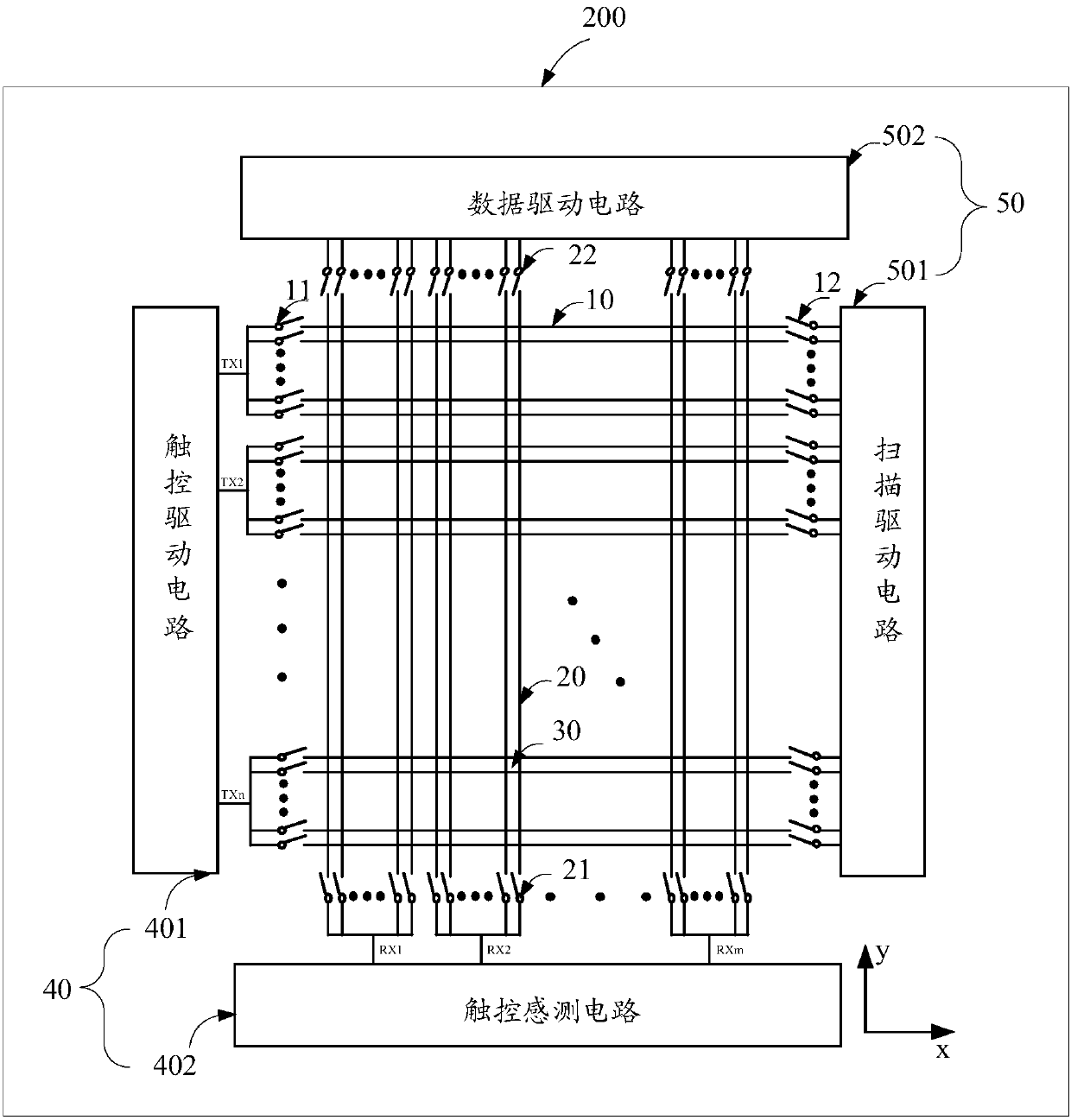

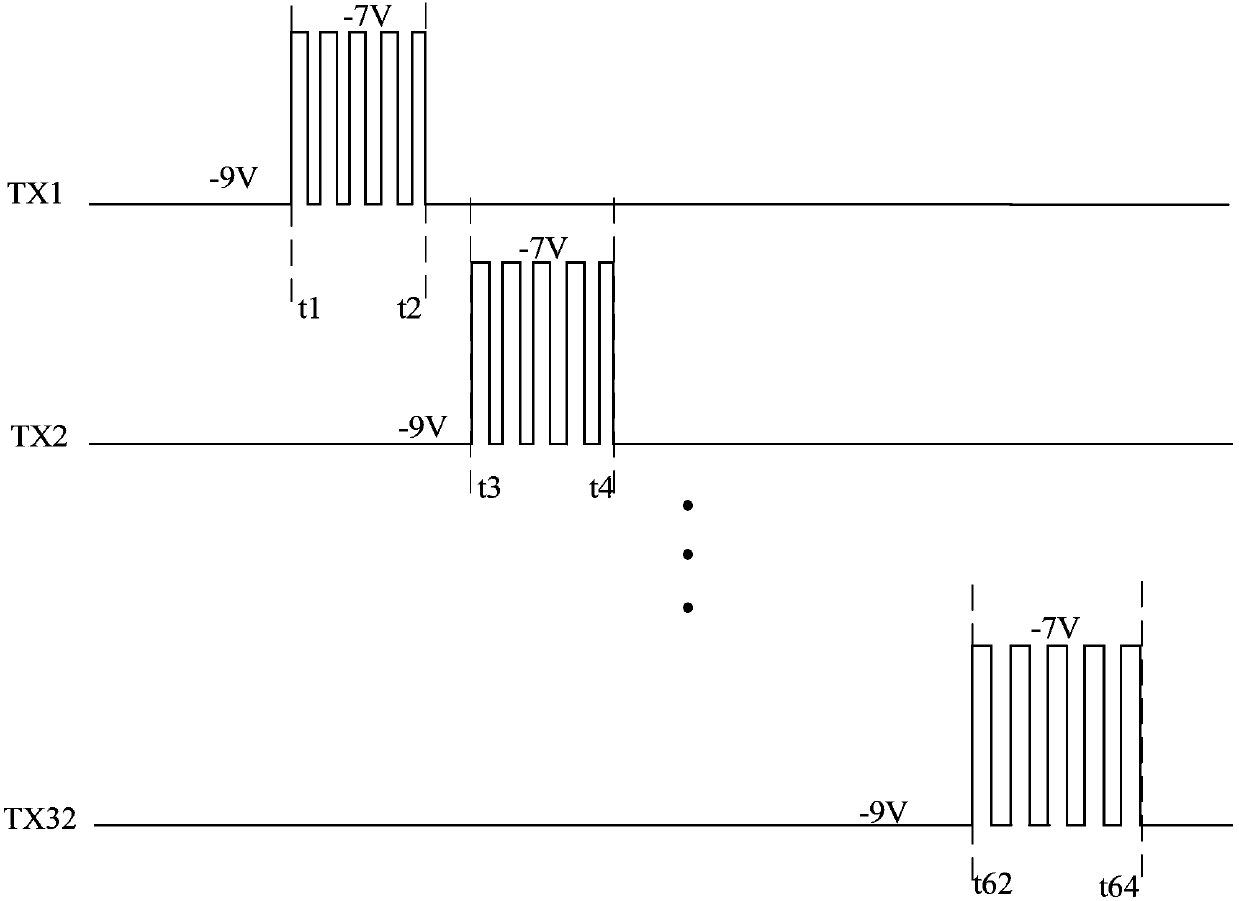

Touch display panel and driving method based on the touch display panel

ActiveCN107608555AReduce complexityLow costStatic indicating devicesInput/output processes for data processingMultiplexingTouch Senses

An embodiment of the present invention discloses a touch display panel and a driving method based on the touch display panel. The touch display panel may include a plurality of first conductors, a plurality of second conductors, and pixel units located at intersections of the first conductors and the second conductors. The pixel units are electrically connected to the first conductors and the second conductors. A first switch and a second switch are arranged on both ends of the first conductors in a first direction. A third switch and a fourth switch are arranged on both ends of the second conductors in a second direction. The first direction is perpendicular to the second direction, and the touch display panel is in a display state or a touch-sensing state in a time-sharing manner. The method can realize the multiplexing of the display and the touch of the first conductors and the second conductors, which not only reduces the process complexity and cost of the touch display panel, butalso meets the demand for thinning of the touch display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Semiconductor packaging component with cooling fan and stacking structure thereof

InactiveCN102290389BReduce thicknessHigh outputSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention discloses a semiconductor packaging component with a cooling fan and a manufacturing method and a stacking structure thereof. The semiconductor packaging component with the cooling fan comprises a substrate, an electronic element, a packaging rubber body and a fan unit, wherein the substrate is provided with a first surface and a second surface, the first surface is provided with a fan arrangement area, the fan arrangement area of the substrate is provided with an open hole and a ventilation hole penetrating through the substrate; the electronic element is arranged on the first surface and around the fan arrangement area and is electrically connected with the substrate; the packaging rubber body is formed on the electronic element and the first surface of the substrate and is provided with a packaging rubber body opening for the exposure of the fan arrangement area; and the fan unit is arranged in the packaging rubber body opening and is electrically connected with the substrate. Since the electronic element is arranged on the part of the substrate outside the fan arrangement area, when the fan unit operates normally, heat produced by the electronic element can be effectively dissipated and can be prevented from being damaged as a result of overheating, and the overall height of the fan unit can be reduced.

Owner:AMTEK SEMICON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com