Positive electrode material, preparation method thereof, and lithium ion battery comprising the positive electrode material

A technology for lithium ion batteries and positive electrode materials, applied in the field of positive electrode materials and their preparation, can solve the problems of unstable use structure, poor cycle performance, low discharge capacity, etc., and achieve enhanced structural stability, excellent lithium ion conductivity, The effect of high volumetric energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

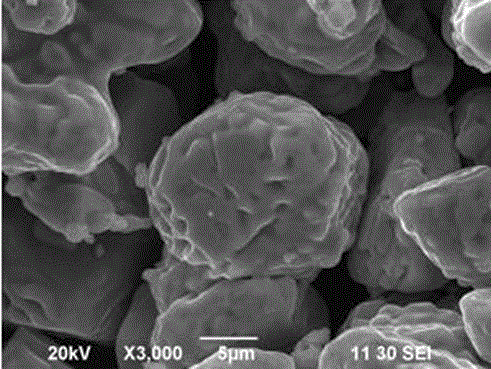

[0035] Example 1: The positive electrode material provided in this example is Li with a coating amount of 3wt%. 1.01 co 0.99 Mg 0.01 o 2 / LiNi 0.5 mn 0.5 o 2 The positive electrode material, the BET of the positive electrode material is 0.35m 2 / g,D 50 =9.0 μm. Among them, Li 1.01 co 0.99 Mg 0.01 o 2 / LiNi 0.5 mn 0.5 o 2 Expressed in Li 1.01 co 0.99 Mg 0.01 o 2 As the bulk material, LiNi 0.5 mn 0.5 o 2 It is the positive electrode material of the surface layer material, the same below.

[0036] The preparation method is as follows: Weigh a certain mass of lithium acetate, manganese acetate, nickel acetate and citric acid into 400mL of water, stir to dissolve them to form a lithium-nickel-manganese mixed solution, and adjust the pH of the solution to 7.8; add 250g of bulk phase Material Li 1.01 co 0.99 Mg 0.01 o 2 powder, stir evenly; adjust the pH of the solution to 11.8, stir and mix evenly; after drying the above mixed solution, first roast it in an...

Embodiment 2

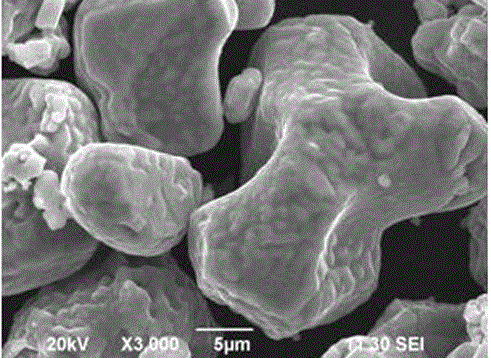

[0037] Example 2: The positive electrode material provided in this example is LiCo with a coating amount of 1wt%. 0.998 Ti 0.002 o 2 / Li 1.02 Ni 0.5 mn 0.498 Al 0.002 o 2 The positive electrode material, the BET of the positive electrode material is 0.27m 2 / g,D 50 =15.0 μm.

[0038] The preparation method is as follows: Weigh a certain mass of lithium nitrate, manganese nitrate, nickel nitrate, aluminum nitrate and ammonia water and add them to 300mL water, stir to dissolve them to form a mixed solution of lithium nickel manganese aluminum, and adjust the pH of the solution to 6.2; add 250gLiCo 0.998 Ti 0.002 o 2 Powder, stir evenly, adjust the pH of the solution to 10.1, stir and mix evenly; after drying the above mixed solution, first bake it under an air atmosphere at 550°C for 4 hours, and then bake it under an air atmosphere at 1000°C for 4 hours to obtain the Cathode material.

Embodiment 3

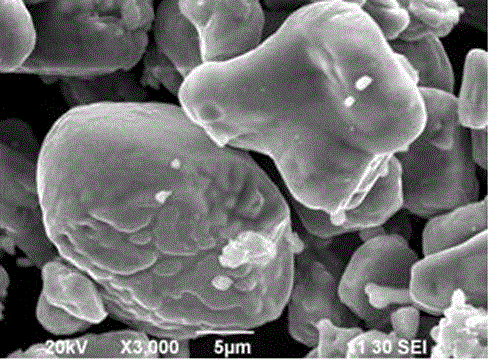

[0039] Example 3: The positive electrode material provided in this example is LiCo with a coating amount of 8wt%. 0.99 Ni 0.01 o 2 / LiNi 0.5 mn 0.45 Zr 0.05 o 2 The positive electrode material, the BET of the positive electrode material is 0.22m 2 / g,D 50 =18.0 μm.

[0040] The preparation method is as follows: Weigh a certain mass of lithium hydroxide, manganese nitrate, nickel acetate, zirconium nitrate and tartaric acid and add them to 400mL of water, stir to dissolve them to form a lithium nickel manganese zirconium mixed solution, and adjust the pH of the solution to 6.7; Add 200gLiCo 0.99 Ni 0.01 o 2 Powder, stir evenly, adjust the pH of the solution to 11.2, stir and mix evenly; after drying the above mixed solution, first roast it in an air atmosphere at 700°C for 5 hours, and then roast it in an air atmosphere at 800°C for 15 hours to obtain the Cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com