Five-piece type high-pixel imaging lens

An imaging lens and high-pixel technology, applied in optical components, optics, instruments, etc., can solve the problems of unreasonable setting of focal power, lens spacing and lens shape, and inability to meet large aperture, ultra-thin, wide-angle, etc. Achieve the effect of shortening the overall length, high imaging quality, and meeting the shooting needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

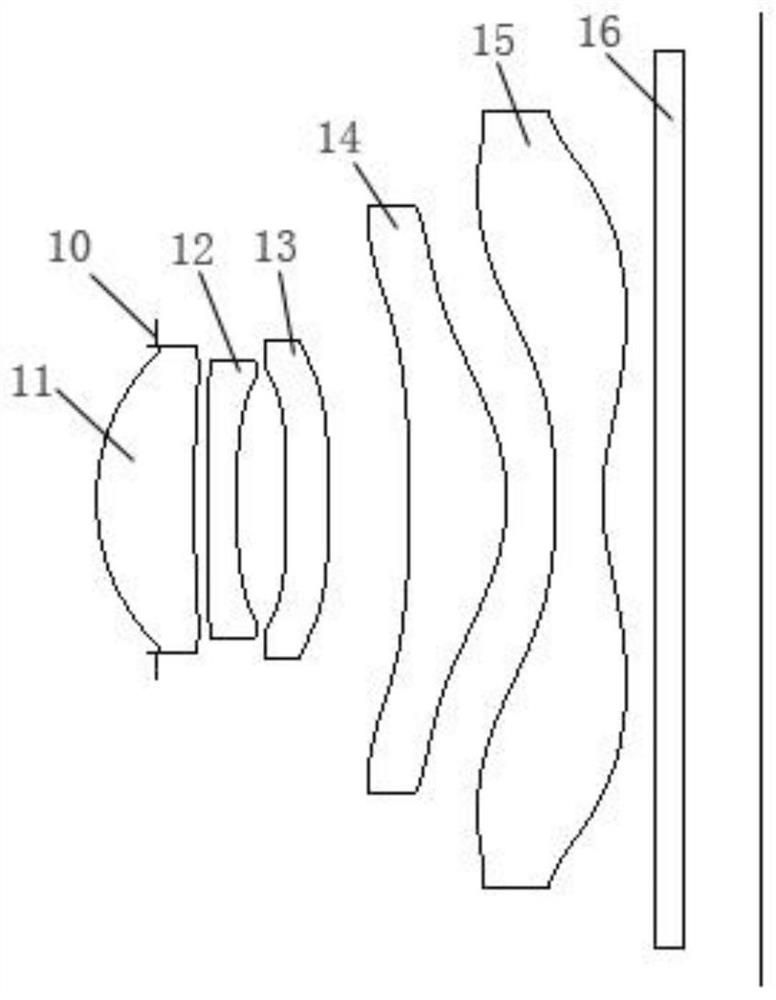

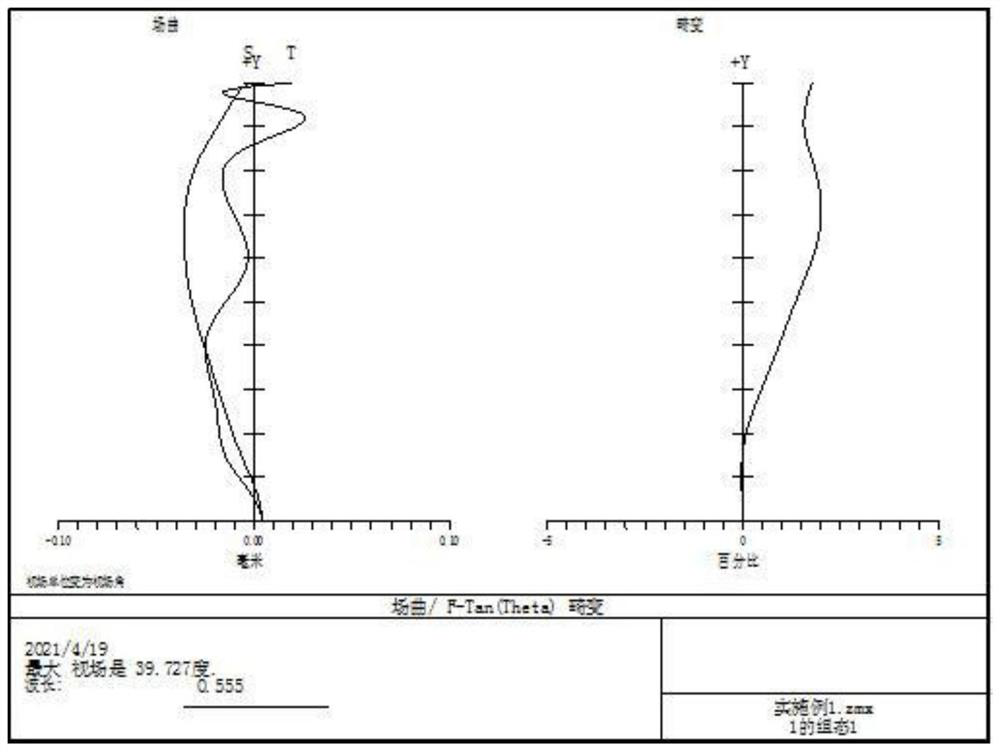

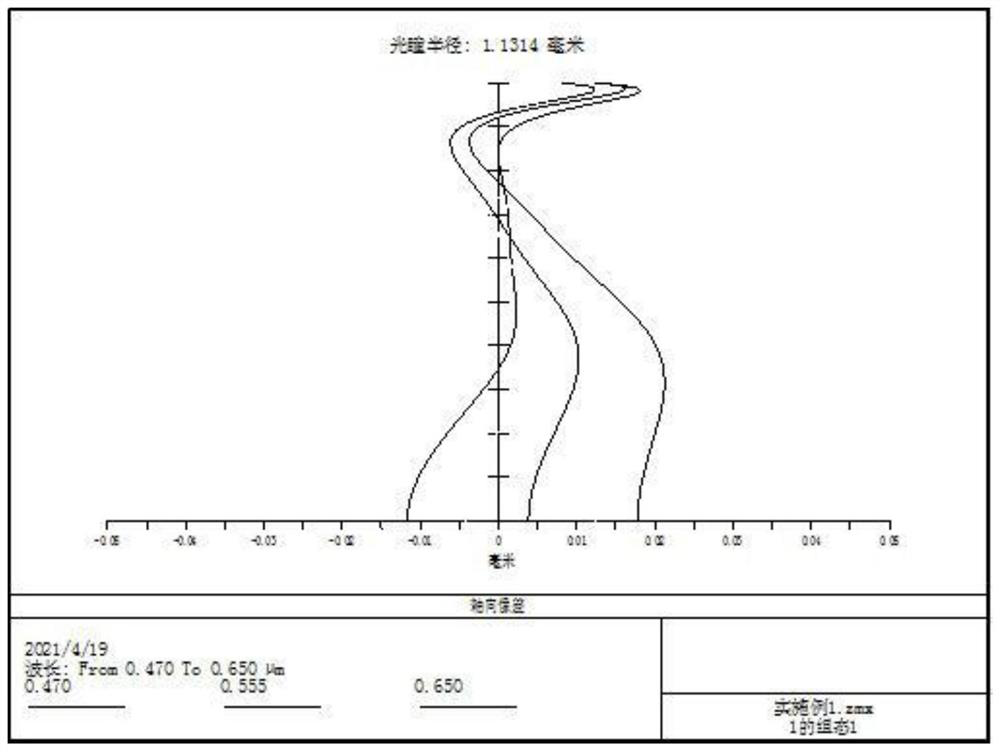

[0059] Please combine figure 2 and image 3 , in the first embodiment, the five-chip high-pixel imaging lens satisfies Table 1-1, Table 1-2, and Table 1-3.

[0060] Table 1-1 is the basic parameters of the five-chip high-pixel imaging lens of the first embodiment:

[0061]

[0062] Table 1-2 is the aspheric coefficient of each lens in the first embodiment:

[0063]

[0064] Table 1-3 is the value of each conditional expression in the first embodiment:

[0065]

[0066]

no. 2 example

[0068] Please combine Figure 4 to Figure 6 The five-element high-resolution imaging lens of this embodiment includes a first lens 21 , a second lens 22 , a third lens 23 , a fourth lens 24 , and a fifth lens 25 in sequence from the object side to the image side. During specific implementation, an aperture 20 is provided on the object-side surface of the first lens 21 , and a filter 26 is provided on the image side of the fifth lens 25 .

[0069] It should be understood that the five-chip high-pixel imaging lens in the second embodiment satisfies the bending force, surface unevenness, and various expressions in the above-mentioned first embodiment, and details are not repeated here.

[0070] In the second embodiment, the five-chip high-pixel imaging lens satisfies Table 2-1, Table 2-2 and Table 2-3.

[0071] Table 2-1 is the basic parameters of the five-chip high-pixel imaging lens of the second embodiment:

[0072]

[0073] Table 2-2 is the aspheric coefficient of each l...

no. 3 example

[0079] Please combine Figure 7 to Figure 9 The five-piece high-pixel imaging lens of this embodiment includes a first lens 31 , a second lens 32 , a third lens 33 , a fourth lens 34 , and a fifth lens 35 in sequence from the object side to the image side. During specific implementation, an aperture 30 is provided on the object-side surface of the first lens 31 , and a filter 36 is provided on the image side of the fifth lens 35 .

[0080] It should be understood that the five-chip high-pixel imaging lens in the third embodiment satisfies the bending force, surface unevenness, and various expressions in the first embodiment above, and details are not repeated here.

[0081] In the third embodiment, the five-piece high-pixel imaging lens satisfies Table 3-1, Table 3-2 and Table 3-3.

[0082] Table 3-1 is the basic parameters of the five-chip high-pixel imaging lens of the third embodiment:

[0083]

[0084]

[0085] Table 3-2 is the aspheric coefficient of each lens in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com