Cross-under type heat pipe structure and manufacturing method thereof

A production method and technology of heat pipes, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of high vaporization rate and condensation rate, dry burning, dry burning of heat pipes, etc., to reduce thickness, increase contact area, and improve heat conduction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The detailed description and technical content of the present invention will be described as follows with the accompanying drawings, but the attached drawings are only for illustration purposes and are not intended to limit the present invention.

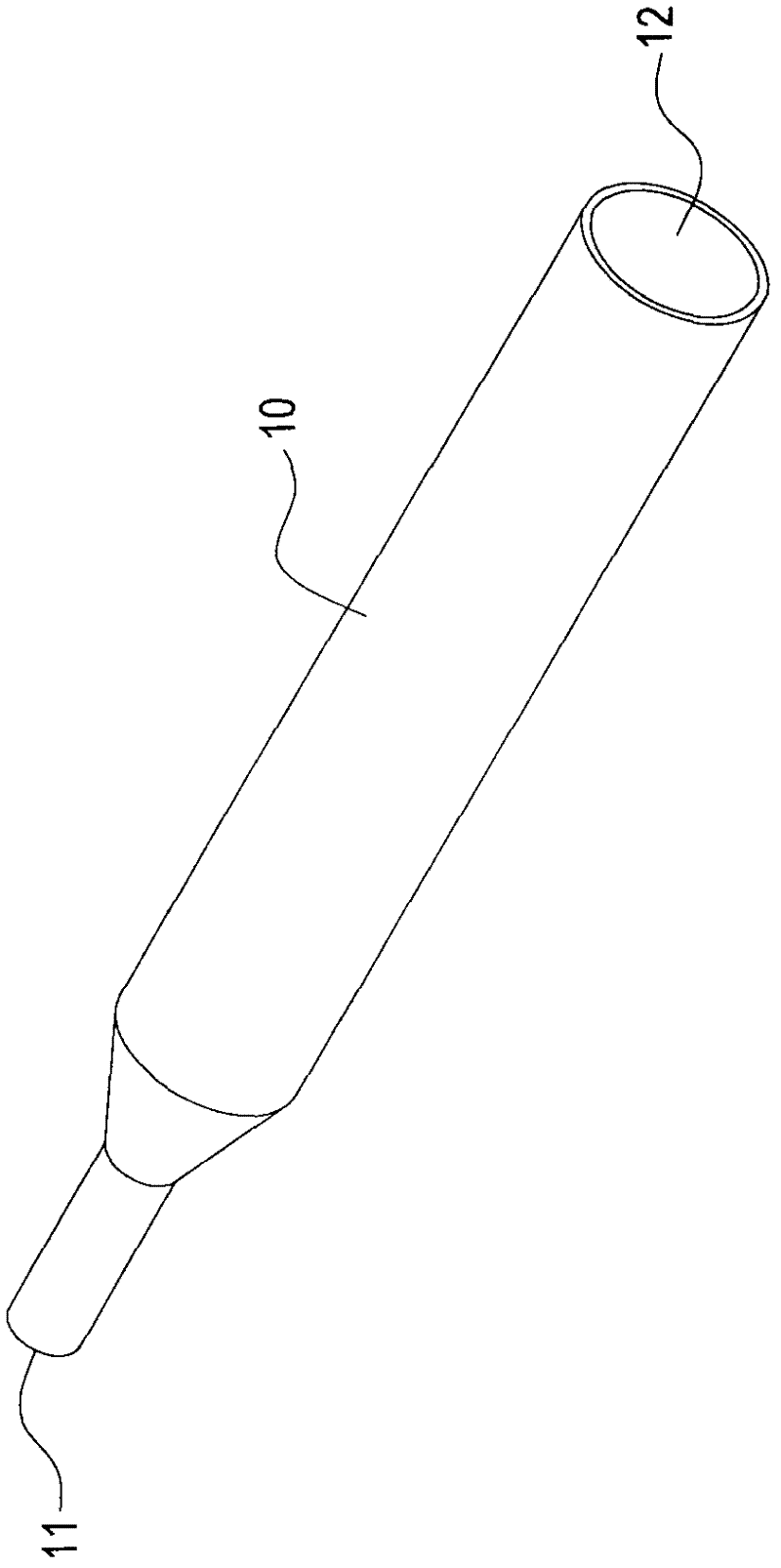

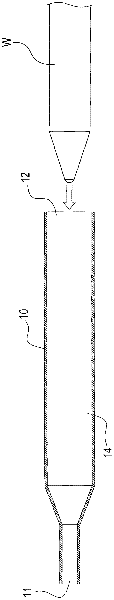

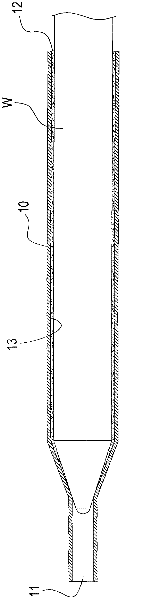

[0076] Please refer to Figure 1 to Figure 10 , which shows the first embodiment of the present invention. The present invention provides a through-type heat pipe structure 1 and a manufacturing method thereof. The fabrication method of the through-type heat pipe structure 1 of the present invention will be described below according to the accompanying drawings, so as to help understand the composition of the through-type heat pipe structure 1 of the present invention.

[0077] The manufacturing method of the threaded heat pipe structure of the present invention, its steps comprise as follows:

[0078] a) providing a first pipe body, the two ends of the first pipe body are respectively formed with a first degassing port and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com