liquid heating vessel

A liquid heating container and heating part technology, which is applied to water-boiling appliances and other directions, can solve the problems of large space of electric kettle, small capacity of liquid-holding device, large volume of electric kettle, etc., so as to improve heat preservation effect, prolong heat preservation time, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

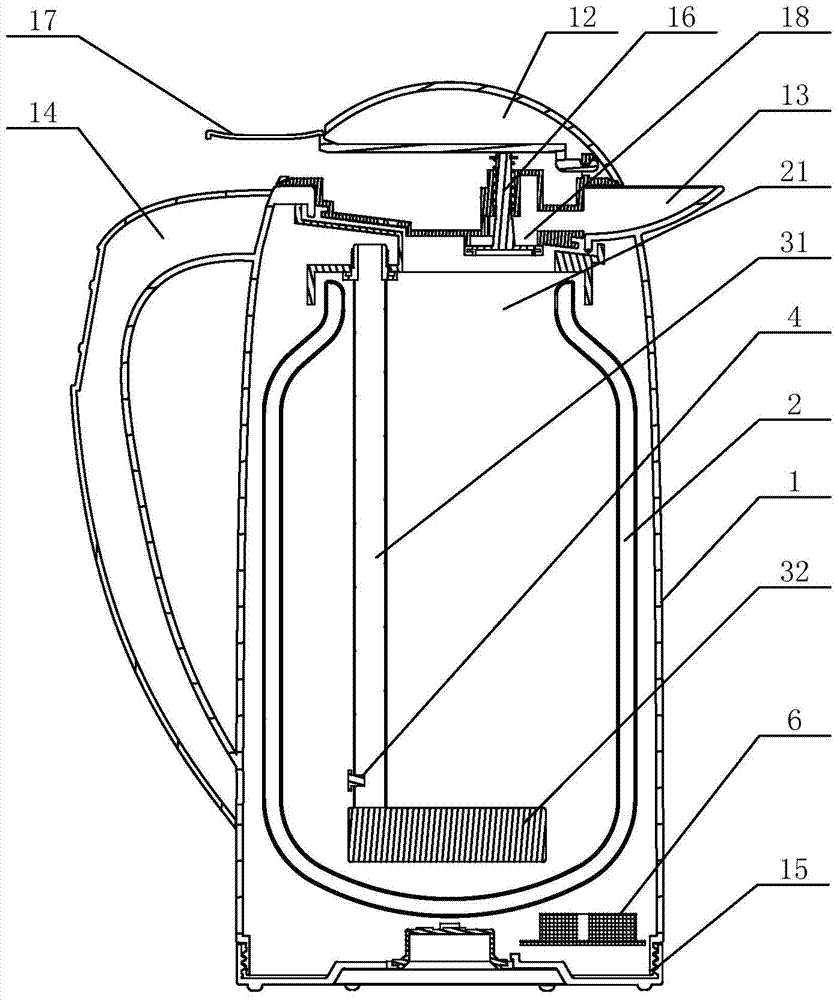

[0034] figure 1 It is a schematic structural diagram of the liquid heating container provided by the first embodiment of the present invention. Such as figure 1 As shown, the liquid heating container provided in this embodiment includes: a housing 1, a liquid holding device 2 having an opening 21 and located in the housing 1, a cover 12 covering the opening 21, and a heating device 3 for heating the liquid . The heating device 3 includes a connection part 31 and a heating part 32 , wherein the heating part 31 enters the liquid storage device 2 from the opening 21 and is fixedly connected to the casing 1 through the connection part 31 . The connecting portion 31 extends along a direction toward the bottom surface of the liquid storage device 2 , and at least part of the heating portion 32 extends along a direction forming a set angle with the extending direction of the connecting portion 31 .

[0035] Specifically, the shape of the housing 1 can be set in various forms, and ...

no. 2 example

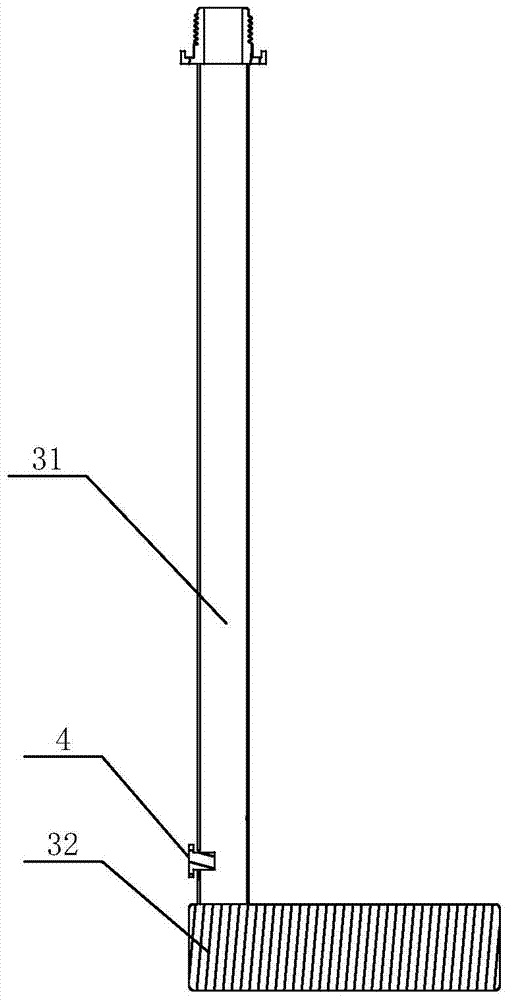

[0049] In order to improve the thermal insulation effect of the liquid heating container, it is usually necessary to reduce the size of the opening 21 in the liquid holding device 2 as much as possible. Therefore, the heating device 3 with a larger size cannot smoothly extend into the liquid holding device 2 from the opening 21 with a smaller size. Adds difficulty to the assembly process of the liquid heating vessel.

[0050] Therefore, this embodiment further improves the structure of the heating device 3 on the basis of the above embodiments: the heating device 3 is set to be foldable, that is, the heating part 32 can rotate relative to the connecting part 31. The example also gives a specific implementation:

[0051] Figure 4 Schematic structural representation of the heating device in the liquid heating container provided for the second embodiment of the present invention Figure 1 , Figure 5 Schematic structural representation of the heating device in the liquid heat...

no. 3 example

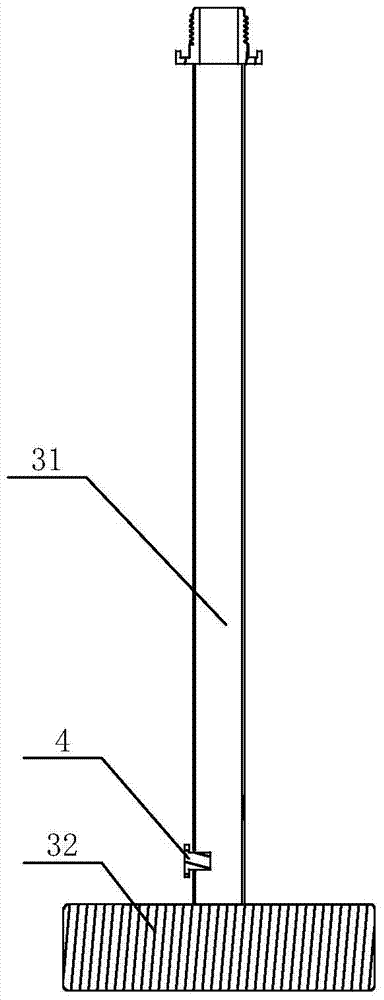

[0054] Figure 6 Schematic diagram of the structure of the heating device in the liquid heating container provided by the third embodiment of the present invention Figure 1 , Figure 7 Schematic diagram of the structure of the heating device in the liquid heating container provided by the third embodiment of the present invention Figure II . As for the heating part 32 being rotatable relative to the connecting part 31 , this embodiment provides a different implementation from the second embodiment.

[0055] Such as Figure 6 and Figure 7 As shown, the heating part 32 includes a first heating part 321 and a second heating part 322 , wherein the second heating part 322 can rotate relative to the first heating part 321 , and the first heating part 321 is connected with the connection part 31 .

[0056] Specifically, the first heating element 321 can be fixed at the end of the connecting part 31, and the second heating element 322 is connected with the first heating elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com