Semiconductor package with cooling fan and its stack structure

A heat dissipation fan and stacking structure technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of affecting the overall height of the heat dissipation fan, thinning the heat dissipation fan, and failing to meet the thinning of electronic products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

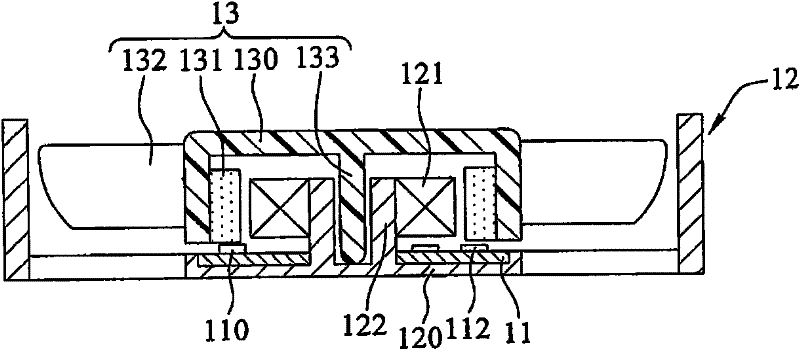

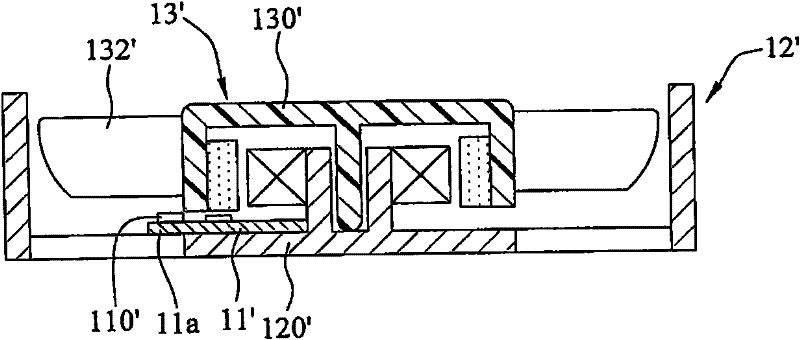

[0074] see 2A to 2E , is a cross-sectional view of the manufacturing method of the semiconductor package with cooling fan of the present invention.

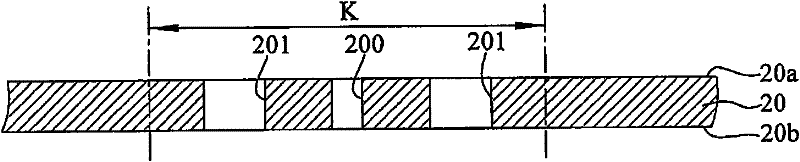

[0075] like Figure 2A As shown, first, a substrate 20 having a first surface 20a and a second surface 20b is provided, and the first surface 20a of the substrate 20 has a fan placement area K; The opening 200 and the ventilation hole 201. like Figure 2A' As shown, in this embodiment, the opening 200 is surrounded by four ventilation holes 201 . Of course, the present invention does not limit the number and shape of the ventilation holes, and there may be only two or more ventilation holes, and the ventilation holes may also be in a honeycomb shape.

[0076] like Figure 2B As shown, a plurality of electronic components 21 are arranged on the first surface 20a around the fan placement area K, and the electronic components 21 are electrically connected to the substrate 20; the electronic components 21 at least include a con...

no. 2 Embodiment

[0099] In another manufacturing method of a semiconductor package with a cooling fan of the present invention, as Figure 3A and Figure 3B As shown, electronic components 21 are disposed on the first surface 20a around the fan placement area K, including functional chips 21c, which are disposed on the substrate 20 and embedded in the encapsulant 22 after forming. In addition, in this preferred embodiment, heat dissipation pads 27 are formed on the first surface 20a and the second surface 20b of the substrate 20; The chip 21c is disposed on the thermal pad 27 on the first surface 20a of the substrate 20 . In addition, conductive connection elements 26' such as solder balls can also be connected to the heat dissipation pad 27 under the second surface 20b, so as to transmit heat energy to the bottom of the substrate 20 and / or communicate with other electrical devices through the conductive connection elements 26'. electrical connection.

no. 3 Embodiment

[0101] like 4A to 4C shown, for the continuation Figure 2E The present invention also provides a semiconductor package stack structure 3 with a heat dissipation fan, including: a semiconductor package 2 with a heat dissipation fan according to the present invention; a bottom electrical device 4, including a carrier 41 and located on the carrier The electronic component 43 on the component 41; and the conductive bonding material 31 such as a solder ball is arranged between the semiconductor package 2 and the bottom electrical device 4, and the substrate 20 of the semiconductor package 2 is connected to the conductive bonding material 31. material 31 , so that an air passage W is formed between the semiconductor package 2 and the bottom electrical device 4 , so that the fan unit 23 can dissipate the heat generated by the bottom electrical device 4 through the air passage W.

[0102] like Figure 4A As shown, the carrier 41 included in the aforementioned bottom electrical dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com