Touch device and touch display device

A touch device, touch panel technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve anti-reflective film creases, increased labor costs, and the overall thickness of the touch device can not be effective Reduced ground and other issues to achieve the effect of reducing light reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

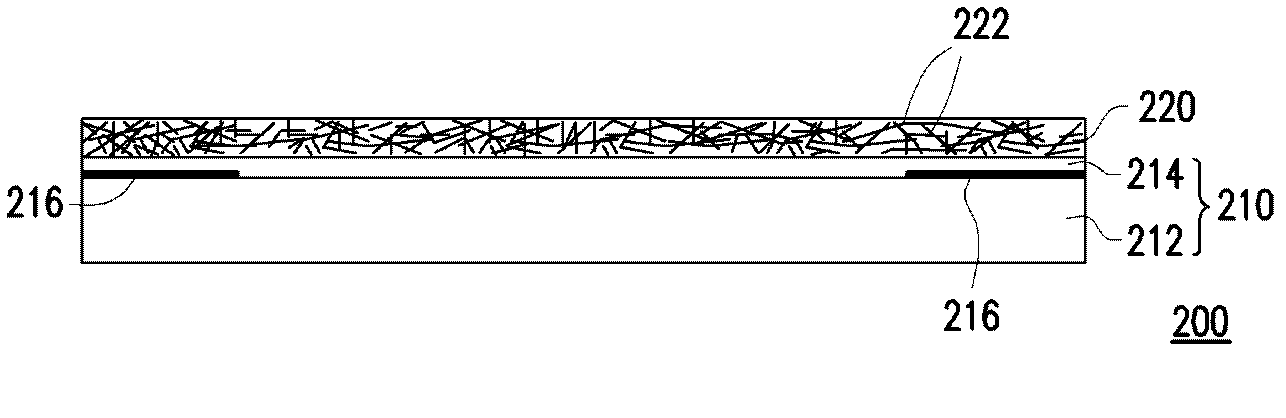

[0026] figure 2 It is a partial cross-sectional schematic diagram of the touch device of the present invention. Please refer to figure 2 , the touch device 200 includes a touch panel 210 and a shielding electrode film 220 . The touch panel 210 includes a substrate 212 and a touch element 214, wherein the touch element 214 is located on the substrate 212, and the substrate 212 is a glass plate or a plastic plate. In this embodiment, the substrate 212 is provided with a decorative layer 216 to The substrate 212 and the decoration layer 216 form a cover lens, such as figure 2 As shown, the decorative layer 216 is located between the substrate 212 and the touch element 214, and the decorative layer 216 is composed of at least one of diamond-like, ceramic, ink and photoresist materials, but the present invention does not limit the arrangement of the decorative layer location and material.

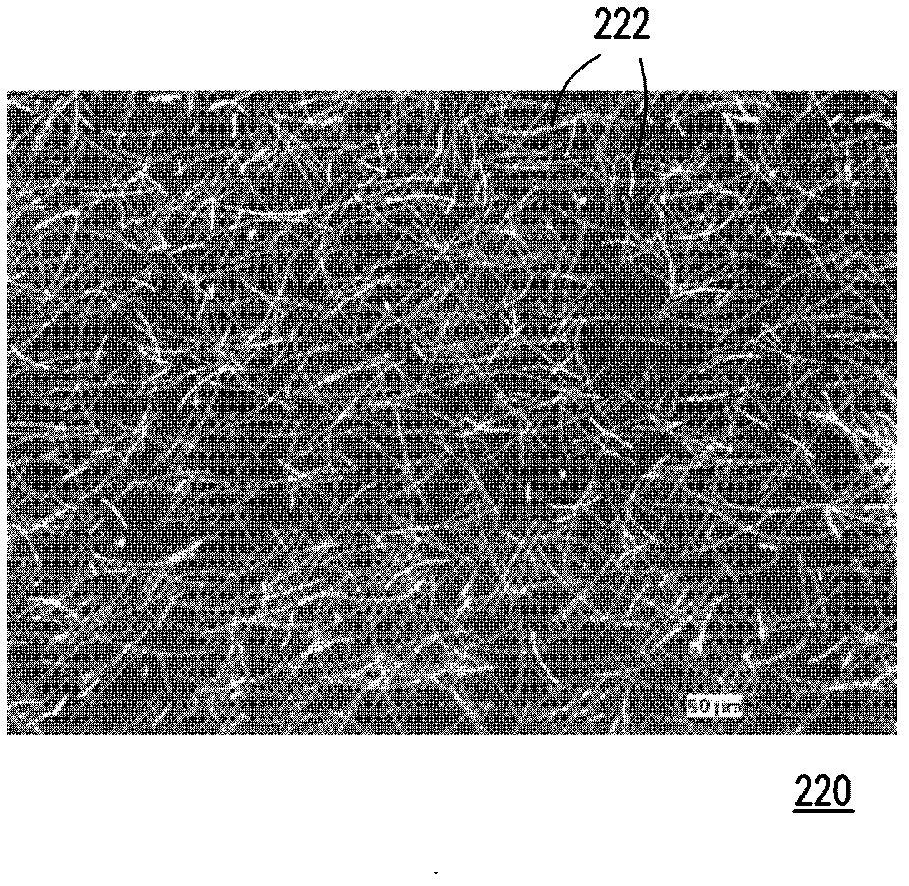

[0027] Please continue to refer to figure 2 The shielding electrode film 220 is dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com