Backlight module and manufacturing method therefor

A technology for a backlight module and a manufacturing method, which are applied in the fields of optics, nonlinear optics, instruments, etc., can solve problems such as development, deficiencies, and unevenness that are unfavorable to the thinning direction of portable flat display devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

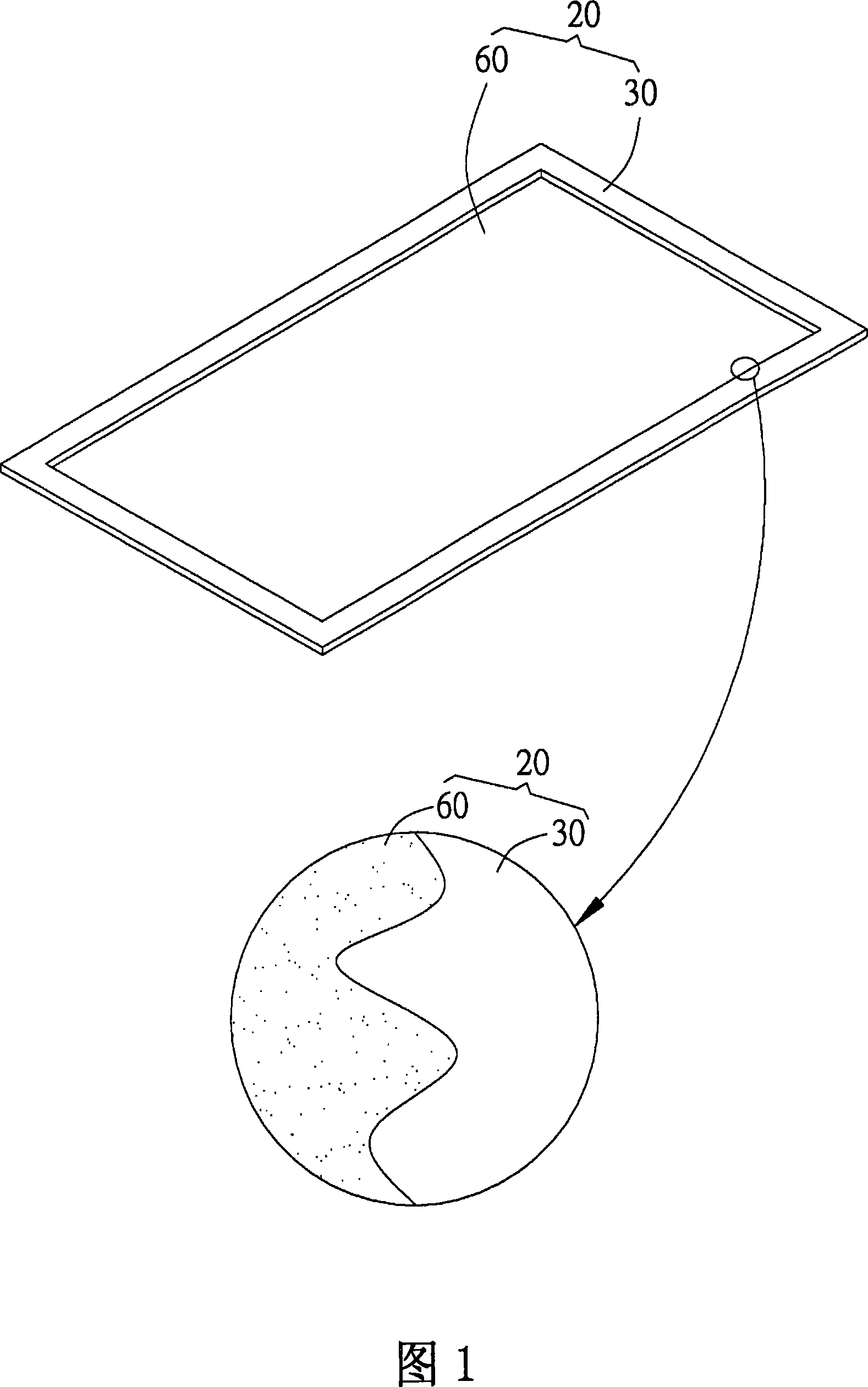

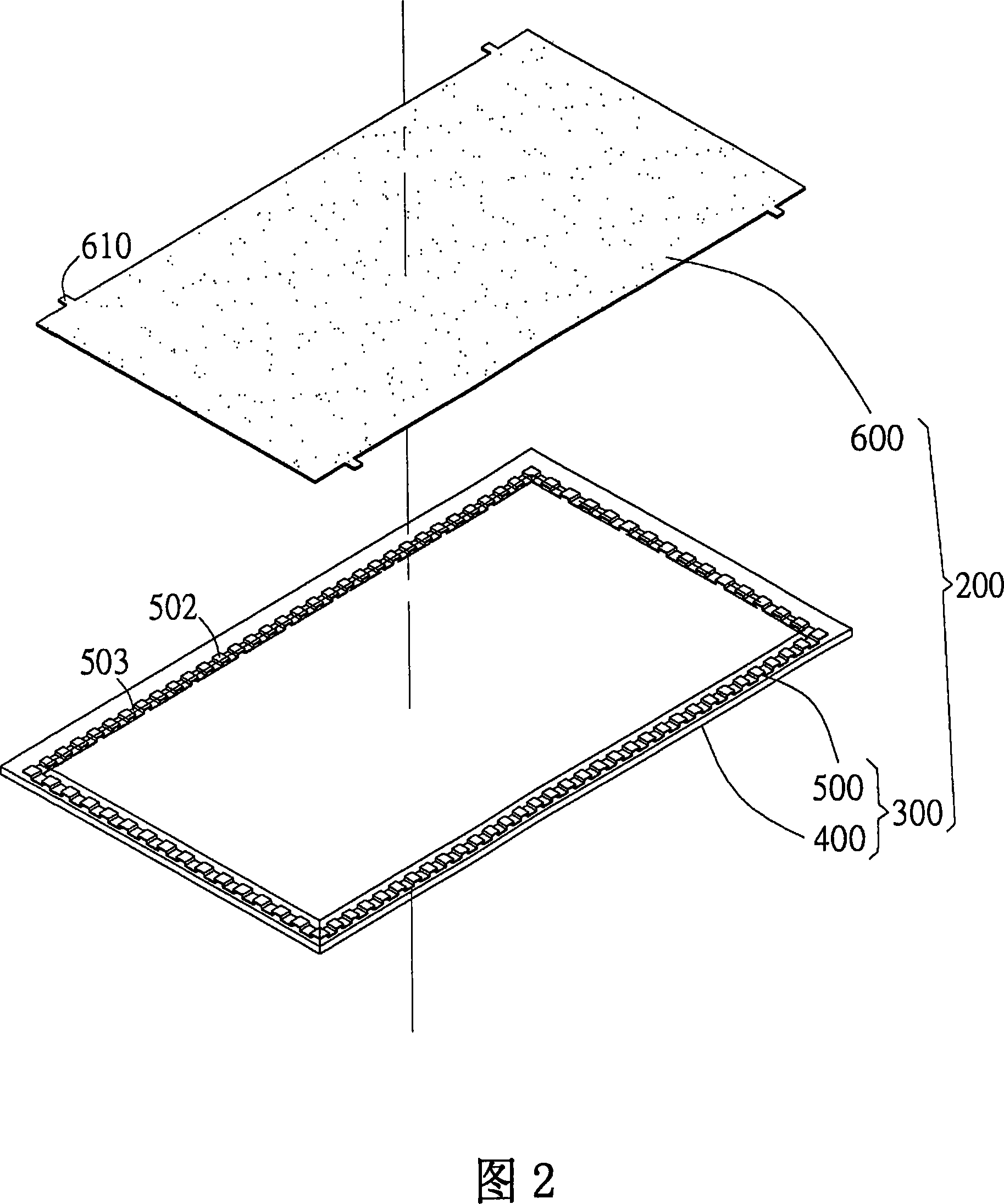

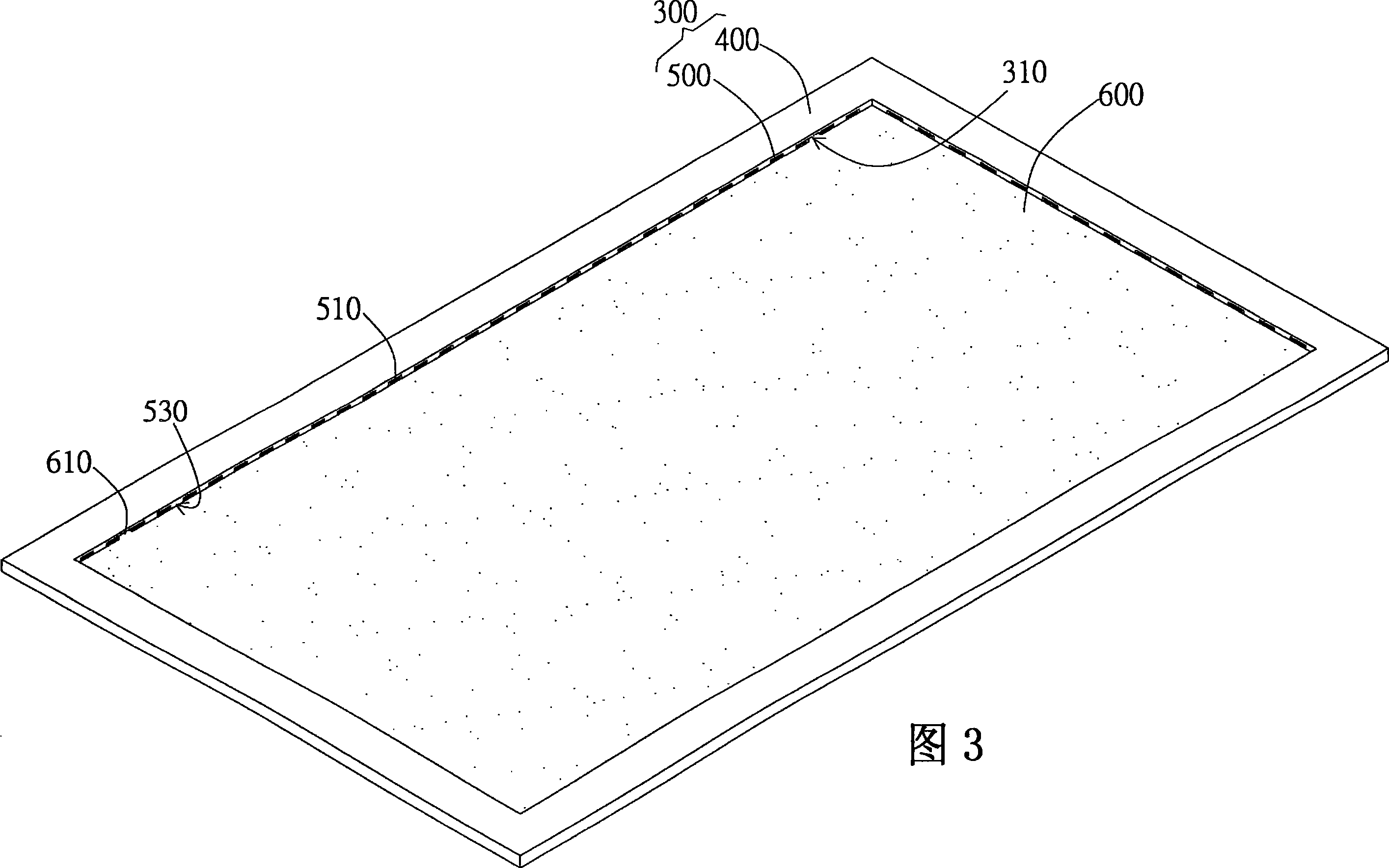

[0039] The present invention provides a backlight module and a manufacturing method thereof. By combining optical plates and at least one material frame to form an integrated structure, the overall strength of the panel is increased and the demand for thinner panel is met. The backlight module of the present invention preferably combines the optical plate, the first material frame, and the second material frame to form an integrated structure by injection technology to increase the overall strength of the panel. In a preferred embodiment, the backlight module of the present invention combines dual-material injection technology to enhance the overall strength of the panel, and connects the plastic frame and the optical plate through a metal frame, such as a light guide plate or other optical plates (such as a diaphragm) Etc. to ensure the maintenance of panel brightness. The backlight module of the present invention is preferably applied to a mobile display device, a portable flat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com