Electromagnetic induction heating apparatus

A technology of electromagnetic induction heating and inductive coil, applied in induction heating devices, induction heating, water heaters and other directions, can solve the problem of not realizing large flow of fluid, large input power, limiting the popularization and application of electromagnetic induction heating technology, and not realizing electromagnetic induction. Heating and other problems, to achieve the effect of simple structure, high power and small fluid pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

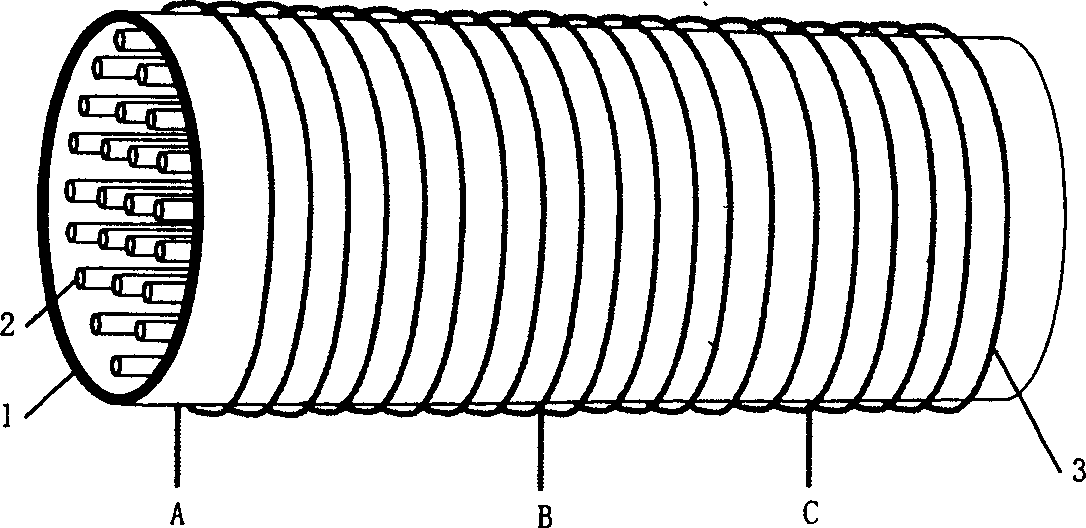

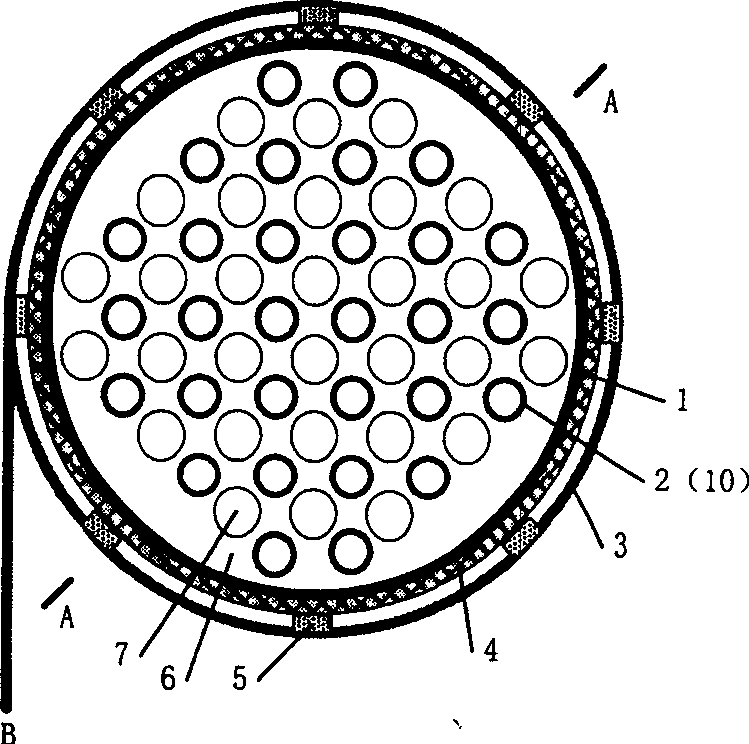

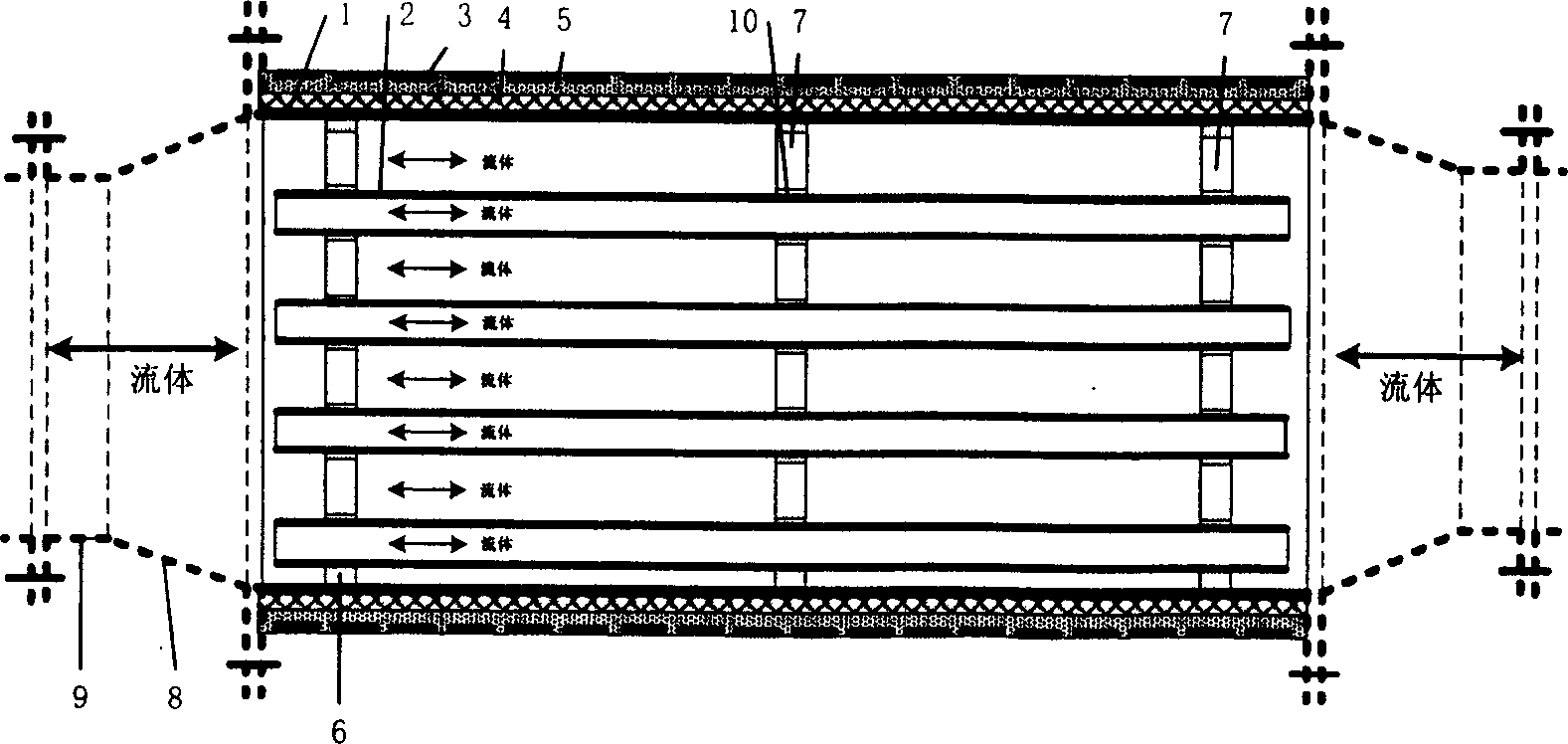

[0027] refer to figure 1 , 2 , 3. This electromagnetic induction heating device is composed of a conductive, non-magnetic and heat-resistant outer heating cylinder 1. A heat insulating layer 4 is arranged on the outer periphery of the outer heating cylinder, and an insulating bracket 5 is wound on the heat insulating layer. Inductance coil 3; an inner heating tube support plate 6 of non-magnetic material is provided in the outer heating cylinder, and several axial inner heating tubes 2 of magnetic material are supported in the support hole 10 on the inner heating tube support plate. Several flow holes 7 are opened on the support plate of the inner heating tube.

[0028] Conductive and non-magnetic heat-resistant external heating cylinder can be made of stainless steel, copper or aluminum alloy and other materials to make circular cylinders, square cylinders, rectangular cylinders or other shapes of cylinders; the inner heating tube of magnetic permeable material can be made o...

Embodiment 2

[0049] refer to Figure 4 , which is an electromagnetic induction heating device that can be used as a heating boiler. Its structure is basically the same as that of Embodiment 1, but the inner heating tube 2 is a triangular tube, and flow holes 7 are added. In this embodiment, the support hole 10 supporting the inner heating pipe also functions as a flow hole at the same time.

Embodiment 3

[0061] refer to Figure 5 , which is a kind of electromagnetic induction heating device for flowing solid heating, its structure is basically the same as that of embodiment 1, but the whole device is vertically arranged. According to the requirements of use, the flow direction of the fluid can be from top to bottom or from bottom to top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com