High-efficiency electromagnetic induction heating device for molten steel in tundish

A technology of electromagnetic induction heating and electromagnetic induction coils, which is applied in the direction of induction heating, coil devices, metal processing equipment, etc., can solve problems such as the reduction of tundish strength, the danger of induction heating production, the increase of tundish maintenance costs and the cost of refractory materials , to achieve the effect of eliminating aging and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

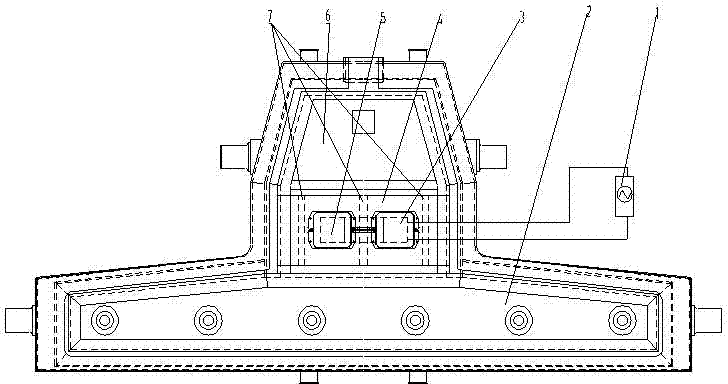

[0014] Such as figure 1 As shown, the device is composed of a power supply device 1, a tundish 2, an electromagnetic induction coil A3, a refractory wall 4, an electromagnetic induction coil B5, a tundish steel cavity 6, and an induction channel 7, wherein the casting cavity of the tundish 2 and The tundish steel cavity 6 is an integrated steel body, which does not require flange connection, and thus does not require insulating materials. The casting cavity of the tundish 2 and the interior of the tundish steel cavity 6 are separated by a refractory wall 4, and the refractory wall An electromagnetic induction coil A3 and an electromagnetic induction coil B5 are arranged inside the body 4, and induction channels 7 are respectively arranged on both sides of the two electromagnetic induction coils (according to the actual space of the tundish and the flow of molten steel, the induction channels between the two coils can be two , can also share one), the electromagnetic induction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com